Vibrating sifter is suitable for screening and filtering various materials such as granular powder, granular powder, mucus, etc., so as to remove impurities or classify the materials.

| Feature | Large capacity fine material screening | Application | Suitable for sieving from 36 microns to 25 mm |

| Material | Carbon Steel, Stainless Steel 304 and 316 | Key words | Vibrating sifte for sale |

| Custom made | Bespoke acceptance by your screening material | Advantage | Offers high throughput capacity to screen bulk solid, powder & slurries,allows 4 sieve levels. |

| Cleaning system | Bouncing Ball Cleaning System/Ultrasonic | Layers | 1-5 layers |

| Mesh size | 2~500 mesh | Voltage | 380V/custom |

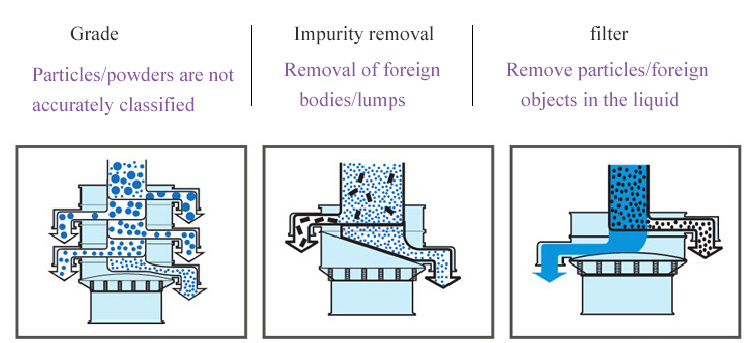

1. Classification: The vibrating sifter can be used to continuously and accurately separate and screen the products, and the multi-layer use can separate and screen out six groups of products with different particle sizes at a time without inconsistent particle size ratio.

2. Liquid removal: This equipment is used in single layer and multi-layer, which can effectively process solid and liquid mixtures, quickly realize solid-liquid separation, and filter out different target materials.

3. Removal of impurities: This equipment can quickly separate a large amount of materials and remove small parts of materials of different sizes.

The material enters the equipment through the material inlet. According to different material screening requirements, the material passes through the sieve of the sieve for layering. In this process, the bouncing ball, a cleaning device located under the sieve, continuously hits the sieve to make the sieve layer layered. The material can be screened through the mesh smoothly, and effectively solve the problem of material blockage. The screened material and the screened material are discharged from different outlets, so as to achieve the purpose of screening and removing impurities or filtering and grading.

Vibrating sifter materials can be divided into three materials: carbon steel, stainless steel, and plastic. In addition, you can choose 1~5 layers of screen design according to the screening purpose, and you can get 2-6 kinds of finished products in one operation. We can also follow Your request designs a special model for you.

Suitable for mass production of industrial screening - it can be used for the separation process of solids in liquid, for the separation of different particle sizes in the same product, for safe screening to eliminate foreign matter, for the homogenization of particles, etc.

Maximum capacity - Allows a production volume of 100 to 25,000 kg/h, depending on the product, mesh size and feed flow of the machine.

Separating products of different specifications - you can achieve 6 different gradation in a single operation as it can be structured up to 5 decks.

Easy handling - Easy to handle due to automatic discharge of material and customized solutions.

| Model |

Feeding Size (mm) |

Frequency (RPM) |

Layers |

Power (kw) |

Capacity (kg/h) |

| DH-400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 0.25 | 200 | |||

| DH-800 | 0.55 | 500 | |||

| DH-1000 | 0.75 | 800 | |||

| DH-1200 | 1.1 | 1200 | |||

| DH-1500 | 1.5 | 1800 | |||

| DH-1800 | 2.2 | 2000 |

| Productivity | |||||

| PRODUCT | MESH OPENING | DH-600 | DH-800 | DH-1200 | DH-1500 |

| Milk powder | 400µ | 350Kg/h | 800Kg/h | 1.800Kg/h | 2.800Kg/h |

| Orange juice | 1000µ | 1.600l/h | 3.500l/h | 8.000l/h | 12.000l/h |

| Sweet pepper | 1000µ | 180Kg/h | 350Kg/h | 1.000Kg/h | 1.300Kg/h |

| Serum lactic | 50µ | 1.000l/h | 2.200l/h | 5.000l/h | 7.500l/h |

| Sugar glass | 150µ | 800 Kg/h | 2.000 Kg/h | 3.000 Kg/h | 3.500Kg/h |

| Wheat flour | 300µ | 300 Kg/h | 600 Kg/h | 1.350 Kg/h | 2.100Kg/h |

| High- Density Polyethylene | 3000µ | 600Kg/h | 1.300Kg/h | 3.000Kg/h | 4.500Kg/h |

| Ammonium sulfate | 350µ | 400Kg/h | 900Kg/h | 2.000Kg/h | 3.100Kg/h |

| Toner powder | 100µ | 90Kg/h | 170Kg/h | 400Kg/h | 600Kg/h |

| Glass powder | 100µ | 270Kg/h | 500Kg/h | 1.300Kg/h | 2.000Kg/h |

| Shredded tire | 1000µ | 300Kg/h | 650Kg/h | 1.500Kg/h | 2.200Kg/h |

| Purines | 125µ | 2.000l/h | 4.000l/h | 10.000l/h | 15.000l/h |

| PET recycled | 5000µ | 400Kg/h | 850Kg/h | 2.000Kg/h | 3.000Kg/h |

| Biofuel oil | 200µ | 800l/h | 1.600l/h | 4.000l/h | 6.100l/h |

| Acrylic paint | 80µ | 500l/h | 1.200l/h | 2.700l/h | 4.200l/h |

Vibrating sifter is suitable for dry and wet screening and grading of powder, granular, fibrous materials or slurries. It is a new type of high-precision fine particle screening equipment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.