Vibrating sieve spring is a kind of elastic element, which is widely used in various vibration equipment. It is an indispensable shock absorbing accessory in the operation of screening equipment. Different types of springs are used in different vibrating sieve applications. How to choose a vibrating sieve spring? Let's first understand the types of vibrating sieve springs.

Vibrating sieve springs are mainly divided into three types: rubber springs, composite springs, and steel springs.

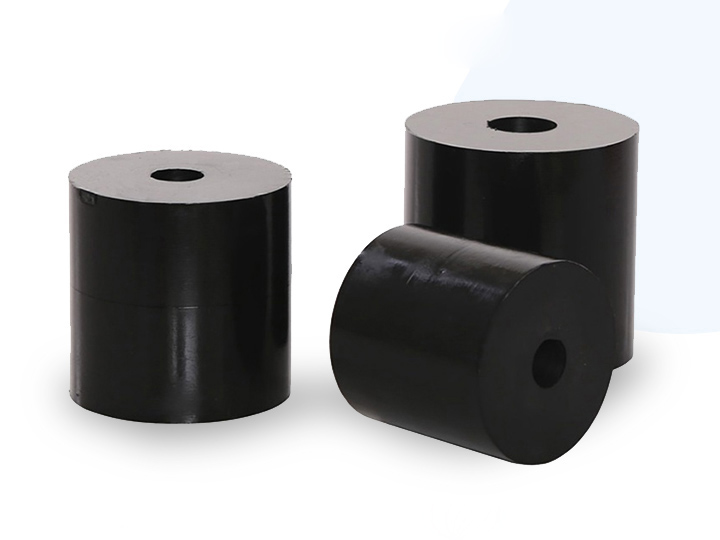

1. Rubber spring

Rubber spring is a kind of high elastic body, which is made of ordinary rubber. It is a spring that uses rubber elasticity to buffer and dampen.

Advantages: The rubber spring has a relatively high internal resistance, which has a good effect on the absorption of sudden shock or high-frequency vibration and sound insulation. The shape of the rubber spring is uncontrolled, and the stiffness in all directions is acceptable. There is no uniform standard for selection according to the actual situation. Good shock absorption effect, small resonance area, excellent cold resistance, air tightness, waterproofness and electrical insulation. There are many kinds of Dahan rubber springs, which can also be customized on demand.

Application: light linear vibrating sieve, stainless steel vibrating sieve, vibrating feeder, ZSG mining vibrating sieve, YA/YK series vibrating sieve, etc. Springs of this material are also used in vibration platforms with a bearing capacity of more than 1 ton.

2. Composite spring

Composite spring is an elastic body composed of metal coil spring and rubber. It integrates the advantages of metal spring and rubber spring, and overcomes the shortcomings of both. It has stable shape and mechanical properties, can withstand load and large deformation, and has a It has the advantages of good vibration and noise reduction effect, stable operation and short resonance time, especially suitable for large-scale vibration equipment in mining, metallurgy, coal and other industries.

Advantages: The shape of the composite spring is not limited, it has large elastic deformation, and it is easy to achieve nonlinear requirements. It has the advantages of higher load capacity and large deformation amount, better shock absorption effect, more stable operation, and shorter resonance interval.

Application: suitable for large-scale vibration equipment in mining, coal, metallurgy and other industries.

3. Steel spring

It is widely used in the machinery industry to control the movement of the parts, ease the impact or vibration, store energy, measure the size of the force, etc.

Advantages: It has the characteristics of long service life and is not affected by ambient temperature.

Application: rotary vibrating screen, stainless steel vibrating sieve, light linear vibrating sieve, small heavy-duty screen, probability screen, etc. In addition, this kind of spring is often used on vibration platforms with a bearing capacity of less than 1 ton.

Summary: Rubber springs are made of polymer materials, their stiffness is greatly affected by temperature, and their high and low temperature resistance and oil resistance are worse than steel springs. Steel springs are not suitable for large vibrating sieves due to the hardness factor. Composite springs combine the advantages of steel springs and rubber springs. Because of the hardness, they are not as good as rubber springs in terms of shock absorption and vibration isolation, and are less used.

The above is a brief introduction to the vibrating sieve spring. For more detailed introduction, please contact Dahan Machinery.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.