Sieve machine is common industrial equipment used for particle size classification and separation of raw materials. Sieve machine can be divided into various types according to different screening principles and structural characteristics. This article will introduce several common types of sieve machines, including vibrating sieve machines, cyclonic sieve machines, air flow sieve machines and electrostatic sieve machines, and discuss their applications in different fields.

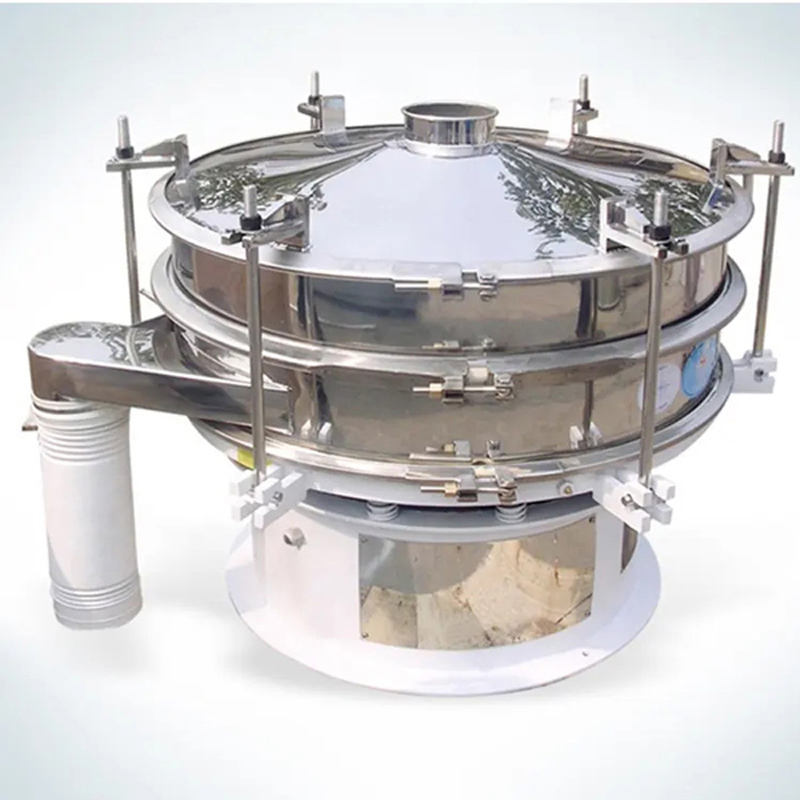

Vibrating sieve machine is one of the most common and widely used screening equipment. It uses vibration force to move the raw materials quickly on the screen surface to achieve particle size classification and separation. Vibrating screening machines can be divided into different types such as linear vibrating sieves, circular vibrating sieves and elliptical vibrating sieves. It is widely used in mining, construction, chemical industry, food and other industries for ore screening, building materials production, chemical raw material processing, etc.

The cyclone sieve uses the action of liquid cyclone to separate raw materials into components of different particle sizes. It uses the rotational motion of the liquid to cause larger particles to settle to the bottom, while smaller particles are discharged from the top with the liquid. The cyclone sieve machine is suitable for raw materials with finer particle size, such as ore slurry, quartz sand, etc. It is widely used in mining, metallurgy, environmental protection and other fields.

The air flow sieve machine uses the action of air flow to classify and separate raw materials. It adjusts the speed and direction of the air flow so that lighter particles are carried away while heavier particles fall into the collector. Air flow sieve machine is suitable for raw materials with finer particle size, such as flour, powder, etc. It is widely used in food processing, chemical, pharmaceutical and other industries.

Electrostatic sieve machines use electrostatic force to separate raw materials. It applies an electrostatic field on the screen to cause the charged particles to be repelled or attracted to achieve classification and separation. Electrostatic sieve machine is suitable for screening fine particles or powdery raw materials, such as plastic particles, powder coatings, etc. It is widely used in plastics, chemicals, electronics and other industries.

In addition to the above-mentioned common sieve machine types, there are also other types of sieve machines, such as rotary vibrating sieve machines, ultrasonic sieve machines, etc. These sieve machines provide more choices and customized screening solutions based on different working principles and application requirements.

Sieve machines are indispensable equipment in industrial production. They can be divided into many types according to different screening principles and structural characteristics. Vibrating sieve machines, cyclonic sieve machines, air flow sieve machines and electrostatic sieve machines are common types of sieve machines. They play an important role in mining, construction, chemical industry, food and other industries. Selecting the appropriate type of sieve machine requires consideration of factors such as the nature of the raw material, screening requirements and application areas. Through reasonable selection and application of sieve machines, production efficiency can be improved, product quality can be improved, and the needs of different industries for particle size classification and separation can be met.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.