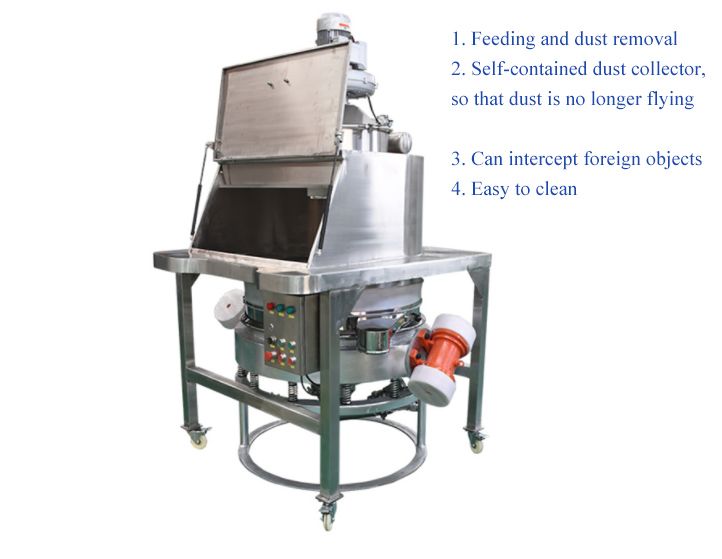

The dust-free feeding station consists of a feeding platform, an unloading bin, a dust removal system, a vibrating screen, etc. It is a manual device for manually pouring small bags of powder or granular materials into the next hopper. What are the advantages of the dust-free feeding station? Is it really possible to do dust-free feeding?

One piece of equipment can dump 50kg, 25kg, 15kg bags, while feeding to prevent dust, it can also realize manual unpacking and reduce labor costs.

The dust during the unloading process can be collected by the dust collection fan. Under the action of the negative pressure of the fan, the dust is sucked into the filter to achieve "gas-material separation". When a lot of materials are collected, they will fall into the silo due to their own weight, reducing material waste. , while protecting workers and preventing factory contamination.

The grille is set to effectively prevent the PE bag from contacting the powder, and it is equipped with a vibrating screen (usually a vertical screen or a rotary vibrating screen), which can effectively intercept foreign objects and ensure that the discharge is qualified.

The equipment is made of 304/316L stainless steel, which is durable, not easy to hang powder, and easy to clean.

The above is an introduction to the advantages of the dust-free feeding station. The upper half of the dust-free feeding station is for dust collection, and the lower half is for raw material screening or raw material transportation. It can be equipped with straight screen, rotary vibrating screen, screw conveyor and positive pressure or Vacuum conveying system

Address:China,Yanjin county forest park gate to the west 1000 meters north road.