Dust-free feeding station, also known as manual dumping station, is used to collect dust generated when powders and bulk solids are dumped in containers such as bags, boxes, barrels, etc., and return the material to the hopper. The system reduces material waste and does not need to clean remote dust collection. sites, while protecting workers and preventing factory contamination.

structure:

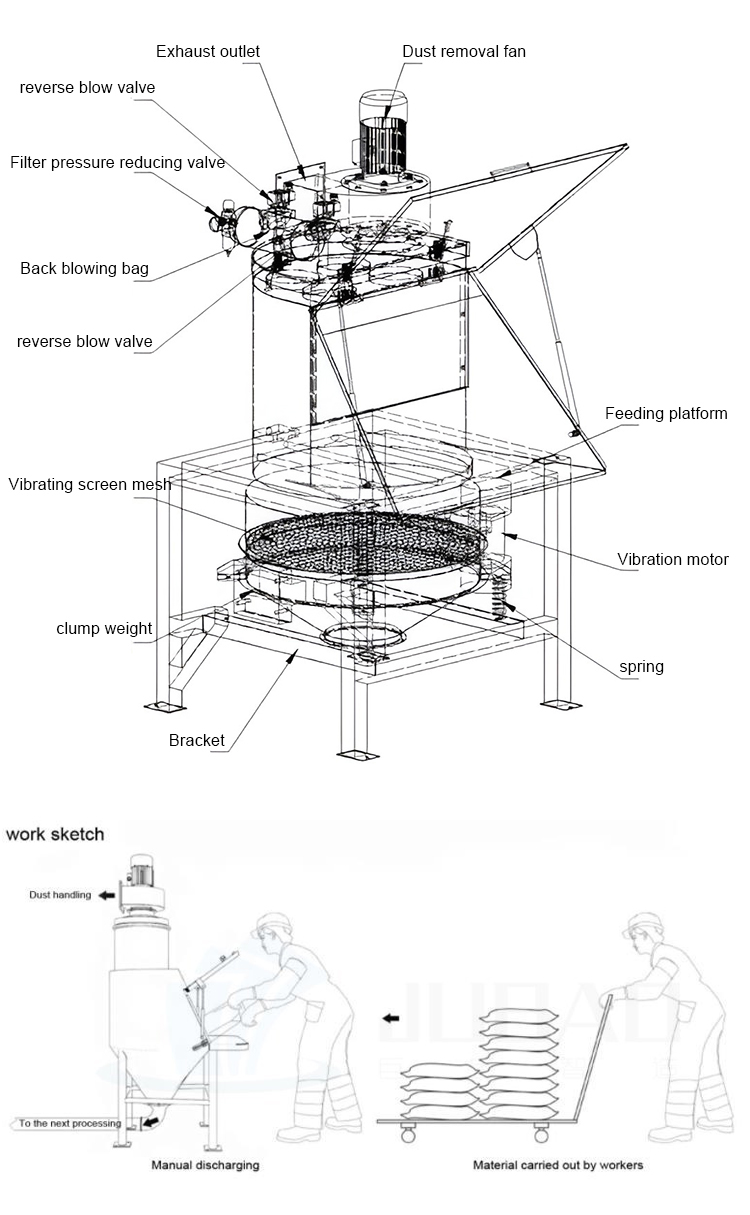

Bag unloading station: the system consists of manual unloading bin, pressure-resistant unloading platform, unloading hopper, vibrating screen, filter system, dust collection system, blowback air bag, vibration motor, etc.

Bag unloading station: The system is composed of a manual unloading bin, a pressure-resistant unloading platform, a safety screen, a filter system, a dust removal system, and a blowback airbag.

work process:

When the material in the bag needs to be discharged into the next process, the bag is manually opened and put into the system. The dust in the discharge process can be collected by the dust collection fan. The vibrating screen (safety screen) can block oversized and foreign objects, and qualified materials can be smoothly discharged to the next process.

When the pouch material needs to be unpacked and poured into the next process, it only needs to be unpacked and put into the system manually. The material dust generated during the feeding process is collected by the dust removal fan. The material is intercepted by the vibrating screen (safety screen) to intercept the bulk material and foreign matter to ensure the smooth input of the particles that meet the requirements.

It is suitable for unpacking, placing, screening and unloading of small bags of materials in the pharmaceutical, chemical, food, battery materials and other industries. When unpacking, due to the action of the dust collecting fan, the material dust can be prevented from flying around.

The above is a detailed introduction to the dust-free feeding station. This machine can be used with conveyors (such as screw conveyors, vacuum feeders) or vibrating screens.

1. The automatic dust collection system can absorb and discharge dust well, prevent the material from generating dust in the process of unpacking and feeding, and improve the working environment.

2. One equipment can dump 50kg, 25kg and 15kg bags, which can meet different processing requirements.

3. A screening and vibration device is installed to facilitate unloading and pipeline transportation, and prevent foreign matter from entering the material during the feeding process.

4. It is not easy to block the material, and a dust collector can also be selected to reduce dust flying, protect the environment and reduce labor intensity.

5. The bottom of the storage tank is equipped with an active hopper, and the size of the storage box can be selected according to the needs.

| type | sifter/td> | drive motor | live load | dead load |

excitation force (KN) |

double-amplitude (mm) |

draught fan | |||||

|

number of plies (s) |

area | structure |

power (kW) |

rotate speed (r.m.p) |

rotate speed | flow | wind pressure | |||||

| DH-800 | 1 | 0.42 | mesh grid | 2x0.18 | 1460 | 800N | 1500N | 2.0*2 | 3~4 | 2900 | 1550-997 | 1217~1641 |

| DH-1000 | 1 | 0.64 | mesh grid | 2x0.25 | 1460 | 500N | 2500N | 5*2 | 3~5 | 2900 | 1550-997 | 1217~1641 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.