The dust-free feeding station, as the name suggests, is a device without dust when feeding, so what advantages does the dust-free feeding station have over ordinary feeding equipment? This article will introduce you to the advantages of the dust-free feeding station:

1. Dust-free feeding

Dust removal test of dust-free feeding station

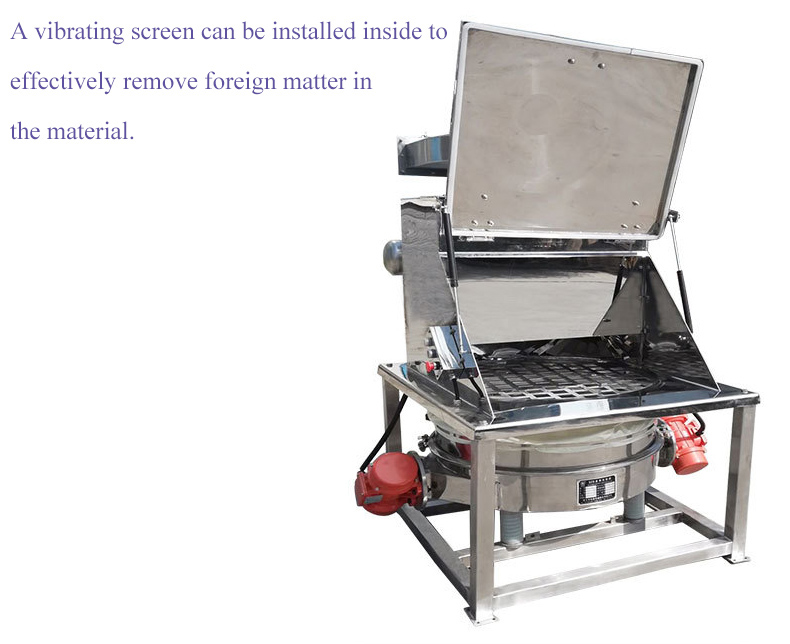

When the small bag of material needs to be unpacked and poured into the next process, it only needs to be unpacked manually and put into the dust-free feeding station. The material dust generated during feeding is collected by the dust collecting fan, and the material passes through the vibrating screen (safety screen mesh). ) can intercept bulk materials and foreign objects, so as to ensure that the finished products (qualified materials) that meet the requirements enter the next process.

2. Airtight bag opening, automatic delivery

The dust-free feeding station is absolutely airtight during the feeding process, and there will be no leakage of any material, and at the same time, dust will be prevented from flying. ; And unpacking is the function of dust collector, which can avoid material dust flying.

3. Reduce work intensity

The overall structure, overall height, and screening device can be designed and adjusted according to the actual site layout of the user. It can also be equipped with vibrating screen, iron remover, vacuum feeder and other equipment for comprehensive use. One device can open 50kg, 25kg, 15kg bags, greatly reducing the labor intensity of workers.

4. Vibration feeding to ensure material purity

The difference from general conveying equipment is that the dust-free feeding station uses vibration to transport materials, which is especially suitable for conveying some materials with poor fluidity. It is screened out and not transported, thus ensuring the purity of the transported material.

5. Easy to clean

The dust-free feeding station is also equipped with a flapping device, two filter devices and some dust removal devices to ensure that the equipment will not block the pipeline due to internal dust or other debris during operation; moreover, the interior can be automatically cleaned after the work. Reduced manual cleaning costs.

6. The spray type self-cleaning high-density filter element is adopted, which does not need to be replaced frequently. The equipment is placed indoors to ensure clean gas and no dust pollution.

If you are interested in our products, you can consult Dahan Machinery at any time.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.