The circular vibrating sieve is named after its appearance. It is also called a circular vibrating sieve. It is mainly used to separate solid powders, solid particles and liquids, and can classify materials according to the particle size. This article will explain the circular vibrating sieve in detail for you. Structure and working principle.

The circular vibrating sieve is composed of dust cover, screen frame, beam ring, screen mesh, punching plate, mesh cleaning device, vibration motor, bottom bucket, vibrating plate and other parts.

Dust Cover: It confines the material and keeps the machine and surrounding environment free from dust.

Vibration motor: YZUL vertical vibration motor, power 0.18KW-4.0KW, it is this motor that causes horizontal, inclined and vertical three-dimensional motion, this motion will increase the speed of the material passing through the circular vibrating sieve, in order to achieve this, the The device is equipped with an unbalanced weight assembly.

Screen frame: The material thickness is 2.0mm~3.0mm, generally made of stainless steel, and carbon steel can also be selected, which limits the product to be processed to the required size and fineness.

Beam ring: It connects the bottom cone and the screen frame, the upper and lower screen frames, and also plays a role in preventing material leakage.

Screen mesh: maintain tension to make it easier for the material to move in the direction of vibration, commonly used 304 stainless steel woven mesh.

Punching plate: carry the screen, prolong the service life of the screen.

Mesh cleaning device: remove the blockages in the screen holes and increase the output, it is made of silicone and rubber bouncing balls, and an ultrasonic cleaning device (635mesh) can also be selected.

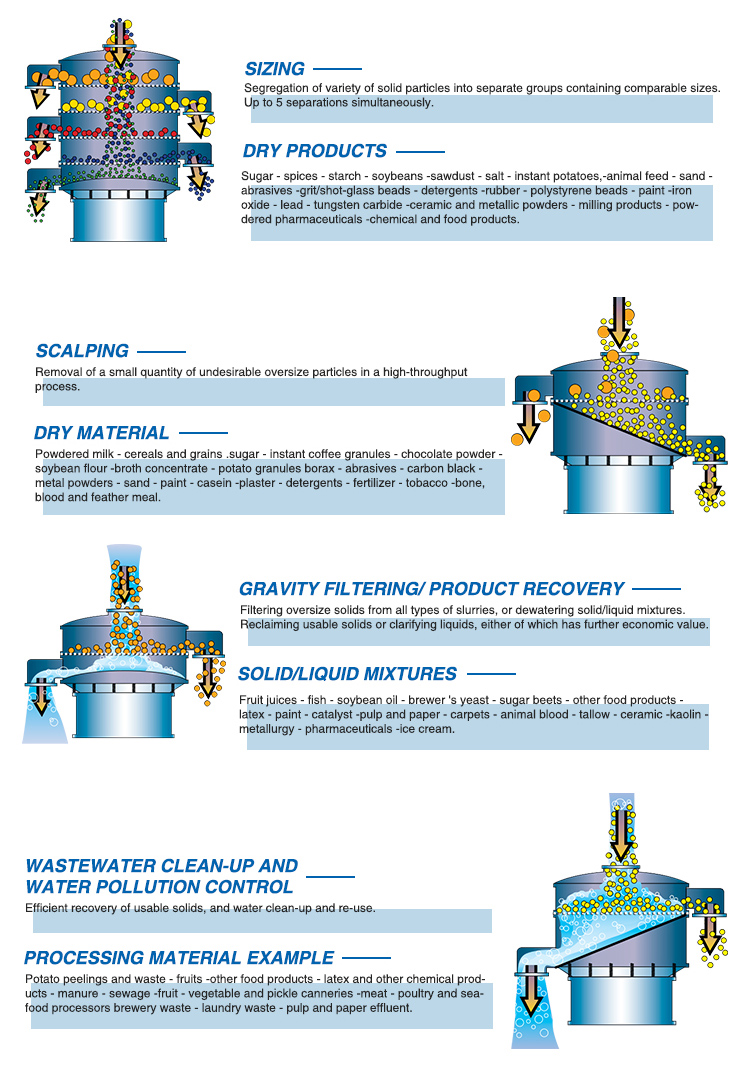

Feed the material to be separated through the feed port (the feed port at the top of the circular vibrating sieve), make sure the cover plate, screen structure and base are fastened with snap rings, due to the unbalanced weight assembly, the vibration motor will be energized, resulting in vibrating motion , the screen will start to vibrate, and then, the material fed into the hopper will pass through the screen according to the particle size, the material larger than the screen size will remain on the screen surface and discharged from the coarse material discharge port, and the material smaller than the screen size will fall into the lower layer. , according to the design of the vibrating screen, you can configure 1-5 layers of screen to achieve particle size classification.

The above is an introduction to the structure and working principle of vibrating screen, circular vibrating sieve can sort, separate or sieve materials to the desired particle size for direct use or further processing, as you can see, the machine uses vibrating motion to shake the screen, thereby Screen out the desired products, which are widely used in food processing, powder processing, feed processing, medicine, chemical and other industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.