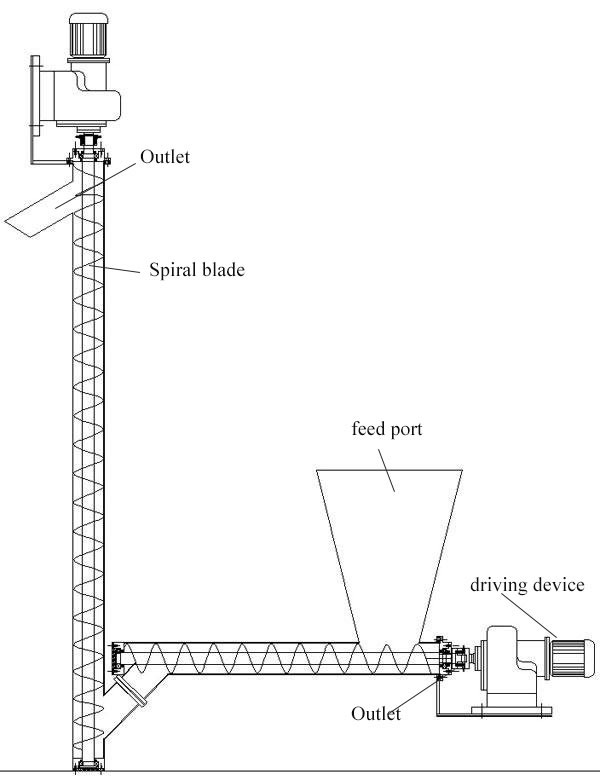

Vertical screw feeder is a common conveying equipment, which mainly consists of a feed port, spiral blades, transmission device and discharge port. It can lift various bulk materials in the vertical direction. The motor drives the screw to rotate through the reducer, and the material is transported to the predetermined position through the rotation. The structure diagram and working principle of the vertical screw feeder are introduced in detail below.

Vertical screw feeder consists of horizontal feeding screw and vertical feeding screw.

The feeding method of the vertical screw feeder is forced feeding. Generally, the horizontal feeding screw and the vertical conveying screw are made into a whole. The diameter of the horizontal feeding screw is the same as that of the vertical feeding screw, but the rotation speed of the horizontal feeding screw is lower than that of the vertical feeding screw.

The material rotates with the screw at high speed, and the material to be conveyed is added from the feed port of the horizontal part, and is sent to the conveyor and the vertical part through the rotating horizontal feed screw, and then the material is pushed up to the discharge port. The discharge port is driven by the vertical screw, The material rotates with the screw at high speed, and the material to be conveyed is fed from the feed port of the horizontal part, and enters the conveyor through the rotating horizontal feed screw. And the vertical part, then use the vertical screw to push the material to the discharge port for discharge.

When the screw speed is high, the centrifugal force on the material is greater than the friction between the material and the surface of the screw, and the material moves to the outer edge of the screw, which exerts pressure on the wall of the trough and generates friction at the same time. When the frictional force is greater than the frictional force between the material and the surface of the screw, the material will slide with the helical surface and follow the trajectory in the opposite direction of the helical rise, that is, the material will be pushed up by the helix of the vertical part, so as to achieve the purpose of vertical upward conveying, otherwise it is just The speed at this time is called the critical speed, and only when the speed of the conveyor is greater than the critical speed, the material can be conveyed upward.

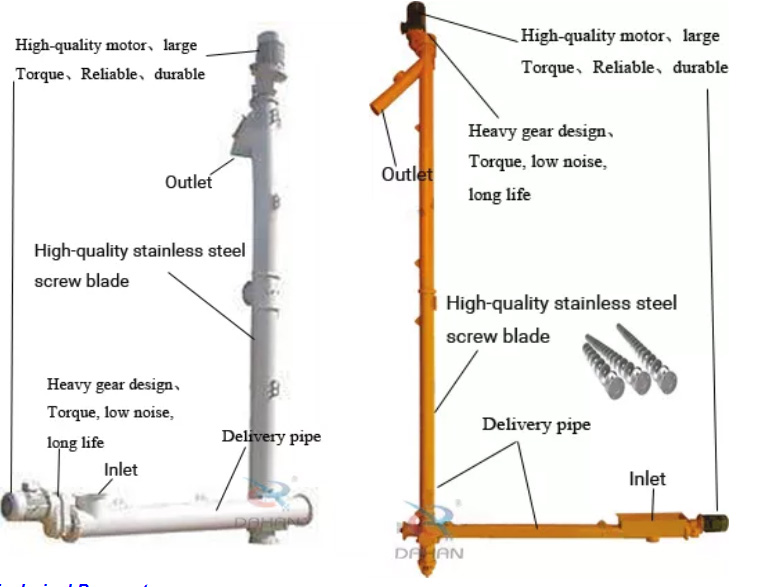

The above is the introduction to the structure diagram and working principle of the vertical screw feeder. The vertical screw feeder is used to transport powdery or granular materials from a low place to a high place. The bulk material can be transported without using internal bearings. Lifting to 8 meters, it is widely used in food, feed, grain, flour processing and other industries.

If you want to know about other aspects of the vertical screw feeder, please directly click on the online chat on the page for consultation. I will answer you in detail. Your consultation is welcome!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.