Usually used to achieve vertical lifting or lowering of materials in a limited space.

![]()

![]()

Price:$500.00-$3,000.00/Set

Consult now and enjoy a 10% discount

Diameter: 114mm, 159mm, 160mm, 250mm, 315mm

Angle: 90 degrees

Height: ≤2.5 meters

Conveying capacity: 1-1000kg/hr

Weight: 25-45kg

Material: carbon steel/stainless steel

Application: Can be used to handle a variety of materials such as granules, powders, pellets and small particles. They are often used to transport materials such as grains, seeds, chemicals, medicines and foods, and to lift or lower materials in a vertical direction.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Small vertical screw conveyor is a mechanical conveying system used to transport materials in the vertical direction. Compared with the traditional horizontal screw conveyor, it has the characteristics of smaller size and ability to handle vertical transportation needs, and is usually used to achieve vertical lifting or lowering of materials in a limited space. This conveyor usually consists of a spiral screw, a pipe or channel, and a drive device, which can effectively transport materials from one height to another.

Small vertical screw conveyors are widely used in many industries and occasions. Here are some common applications:

1. Storage and warehousing facilities: Small vertical screw conveyors can be used to transport materials from the ground to the upper floors of storage facilities or warehouses.

2. Processing plants: Small vertical screw conveyors can be used to transport materials from one processing link to another, especially in factories with limited space or where vertical transportation is required. They can provide efficient material transfer and process control.

3. Packaging lines: Convey materials from packaging machines to packaging boxes or containers. They can provide fast and reliable material transportation and improve the efficiency of packaging lines.

4. Food and beverage processing: It can be used to transport raw materials to different processing links, or to transport finished products from the processing area to the packaging area.

5. Chemical and pharmaceutical industries: Chemical raw materials, drug raw materials, additives, etc. can be transported from one process link to another.

Material feeding: The material enters the spiral body of the screw conveyor from the feed port.

Screw rotation: When the screw conveyor starts, the spiral body begins to rotate, pushing the material along the spiral blades toward the discharge port.

Material conveying: Due to the pushing action of the spiral blades, the material forms a continuous material flow in the screw conveyor and is conveyed forward along the axis of the conveyor.

Gravity action: During the conveying process, the material is affected by gravity and moves along the inclined direction or vertical direction of the conveyor to complete the conveying process.

Discharge: Finally, the material reaches the discharge port and is discharged to the designated location through the discharge port to complete the entire conveying process.

Small vertical screw conveyors can be divided into two different types: stainless steel and carbon steel. The following is a detailed introduction to these two types:

Stainless steel small vertical screw conveyor

Stainless steel small vertical screw conveyor is usually made of stainless steel, which has the characteristics of corrosion resistance, wear resistance and easy cleaning.

This type of screw conveyor is often used in food, medicine, chemical and other industries, where the conveyed materials are required to be pollution-free and odor-free.

Carbon steel small vertical screw conveyor

Carbon steel small vertical screw conveyor is mainly made of carbon steel, which has strong wear resistance and durability.

This type of screw conveyor is often used in building materials, metallurgy, mining and other industries to convey general granular and granular materials.

| Model | 100 | 160 | 200 | 250 | 315 | 400 |

| Screw diameter(mm) | 100 | 160 | 200 | 250 | 315 | 400 |

| Screw pitch(mm) | 100 | 160 | 200 | 250 | 315 | 355 |

| Rotating speed(r/min) | 100 | 120 | 90 | 90 | 75 | 75 |

| Capacity Qφ=0.33(m3/h) | 2.2 | 7.6 | 11 | 22 | 36.4 | 66.1 |

| Power Pd 1=10m(kw) | 1.1 | 1.5 | 2.2 | 2.4 | 3.2 | 5.1 |

Specification only for your reference, size variable as per customer's request. Note: Please use other types of screw conveyors of our company for those larger than 1000 kg/h. |

||||||

Space saving

Small vertical screw conveyors use a vertical conveying method to achieve the lifting or lowering of materials in a limited space. Compared with other traditional vertical conveying equipment, such as bucket elevators or lifts, small vertical screw conveyors have smaller size and footprint, and can better adapt to small spaces.

Flexibility

Small vertical screw conveyors can be customized and adjusted according to specific needs. They can adapt to the handling requirements of different materials and can be designed according to the height requirements of the working scene. In addition, small vertical screw conveyors can also be integrated with other equipment to achieve more complex material conveying systems.

High efficiency

Small vertical screw conveyors have efficient material lifting or lowering capabilities. Through the rotational motion of the screw, they can quickly and reliably convey materials from the bottom to the top or in the opposite direction. This high efficiency can improve production efficiency and reduce human resource costs.

Reliability

Small vertical screw conveyors use sturdy and durable materials and structures, with good mechanical stability and durability. They are able to handle a variety of materials and maintain stable performance and reliable operation in long-term use. Cost and downtime.

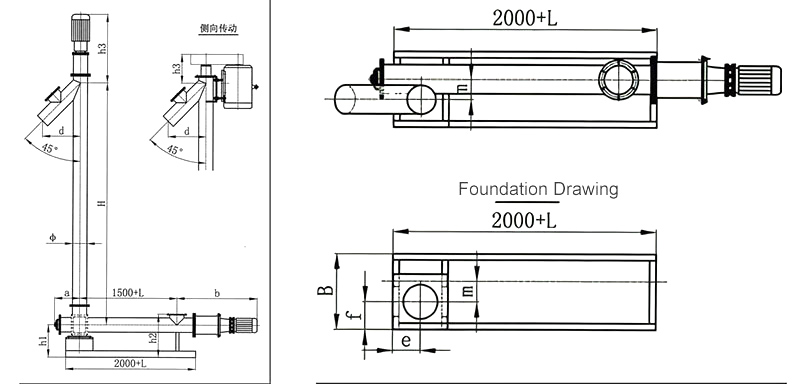

1、Screw: The screw is the main component of the conveyor and is responsible for transporting the material. It is a helical-shaped blade that rotates inside a tube or trough. The design of the screw determines the type of material it can handle and the efficiency of the conveyor.

2、Tube or Trough: The screw is enclosed within a tube or trough, which acts as the container for the material being transported. The tube or trough is typically made of stainless steel or carbon steel and is designed to withstand the weight and pressure of the material.

3、Drive Mechanism: The drive mechanism consists of a motor and a gearbox that provide the power to rotate the screw. The motor provides the necessary rotational force, while the gearbox helps control the speed and torque of the screw. The drive mechanism is typically located at the top or bottom of the conveyor.

4、Inlet and Outlet: The small vertical screw conveyor has an inlet at the bottom, where the material enters the conveyor, and an outlet at the top, where the material is discharged. These openings are designed to facilitate the smooth flow of material into and out of the conveyor.

| Conveying materials | Conveying height (m) |

Transport capacity (t/h) |

Model |

| Sand | 3 | 6 | LC273 |

| Iron oxide | 2.5 | 1 | LC219 |

| Coffee powder | 1.3 | 1 | LC159 |

| Soybean | 1 | 5 | LC160 |

| Aluminum block | 4 | 1 | LC245 |

| Salt | 1.5 | 5 | LC219 |

| Catalyst | 2 | 10 | LC315 |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.