The vertical screw conveyor is suitable for conveying powdery, granular, non-viscous dry materials with a bulk density of ≤1.3t/m, such as grain, oil bran, feed, chemical raw materials, cement, etc., vertically or at a large inclined angle. The temperature of the material generally cannot exceed 80℃, and the vertical screw conveyor is not suitable for loosening the viscous material of the lump. This article will give you a detailed introduction to the structure and working principle of the vertical screw conveyor:

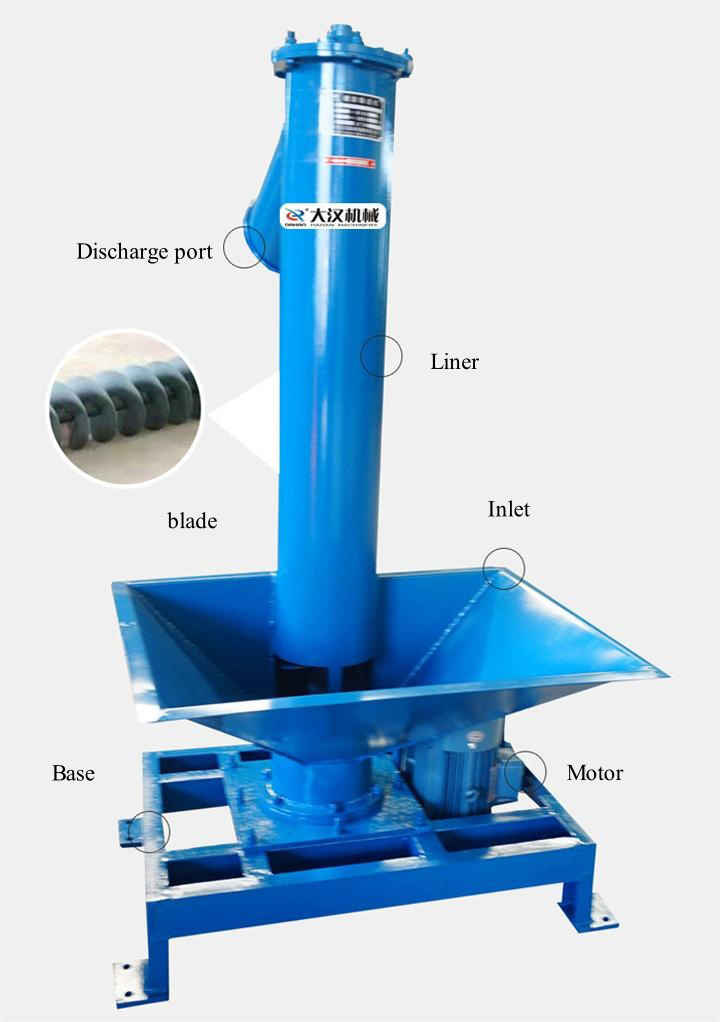

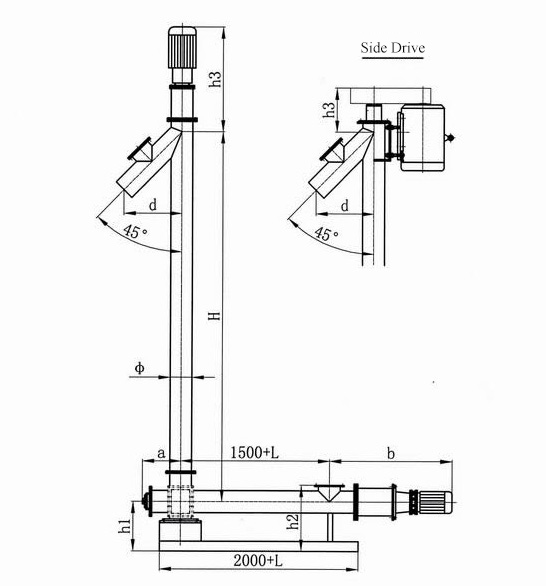

Structure of Vertical Screw Conveyor

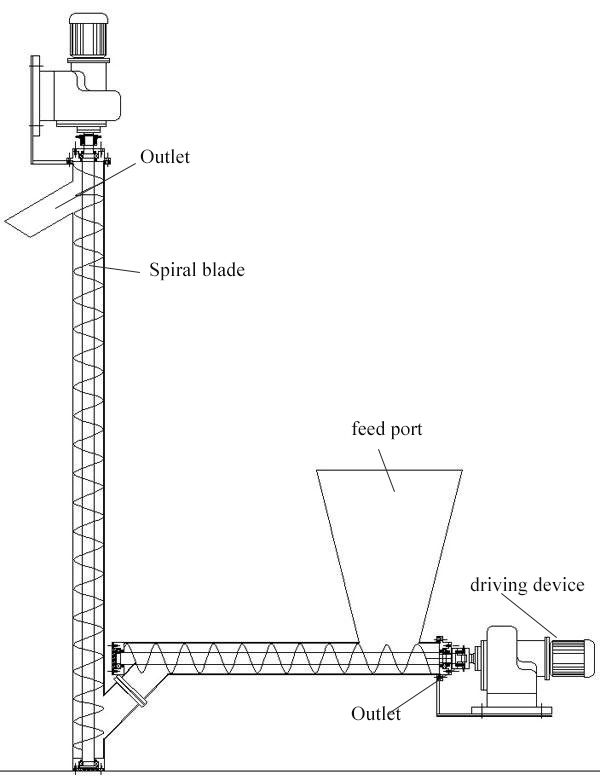

The vertical Screw conveyor is composed of a driving device, a screw, a bearing, a trough, a feed port, and a feed port.

Drive device: adopts the upper drive form. The motor is installed on the head of the main machine, and the power is transmitted to the main shaft via a belt to drive the spiral operation. When the motor power is less than or equal to 15Kw, the single drive is adopted, and when the motor power is greater than 15Kw, the dual drive is adopted.

Spiral: The surface shape of the spiral blade includes solid surface type, belt surface type, blade surface type, etc. according to the different materials conveyed by the vertical screw conveyor.

Bearing: The screw shaft of the vertical screw conveyor has a thrust bearing at the end of the material movement direction to give the axial reaction force of the screw with the material. When the length of the machine is long, the middle hanging bearing should be added.

Trough: The trough is made of carbon steel and stainless steel, but it is usually made of 2~4mm thick thin steel plate. The two side walls of the cross section are vertical, and the bottom is semicircular.

Working Principle of Vertical Screw Conveyor

During the conveying process, the material rotates at a high speed with the spiral. Due to the centrifugal force, the material forms several concentric layers in the trough, and the outermost layer of the material is close to the trough wall. When the spiral speed is not high, the friction force between the material and the spiral surface is greater than the centrifugal force received by the material, and the material and the spiral rotate together to maintain a relatively static state; when the spiral speed is high, the centrifugal force received by the material is greater than the material and the spiral surface The frictional force of the material. The material moves to the outer edge of the spiral, creating pressure on the trough wall and at the same time generating friction. Only when this frictional force is greater than the sum of the frictional force between the material and the spiral surface and the component force of the gravity of the material, the material It will slide with the spiral surface and rise along the spiral trajectory in the opposite direction, that is, the material is pushed up by the vertical part of the spiral, so as to achieve the purpose of vertical ascending transportation.

The structure and working principle of the vertical screw conveyor mentioned above, I hope it will be helpful to you.

Nevertheless, you still have any confusion, so please let Dahan Machinery experts answer for you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.