Copper electrolytic powder is a fine powder produced during the electrolysis process of copper refining. Copper electrolytic powder sieving machine is a special tool used to separate copper electrolytic powder particles of different sizes. This article will introduce you in detail about the sieving machine in copper electrolytic powder. application.

Electrolytic copper powder is produced during the electrolysis process of copper refining, the obtained powder has different particle sizes, the screening process helps to remove any oversized or undersized particles, remove any impurities that may exist in the powder, and ensure the final Purity and quality of copper products.

Depending on the specific characteristics of the powder and the screening equipment used, screening copper electrolytic powders can present several challenges:

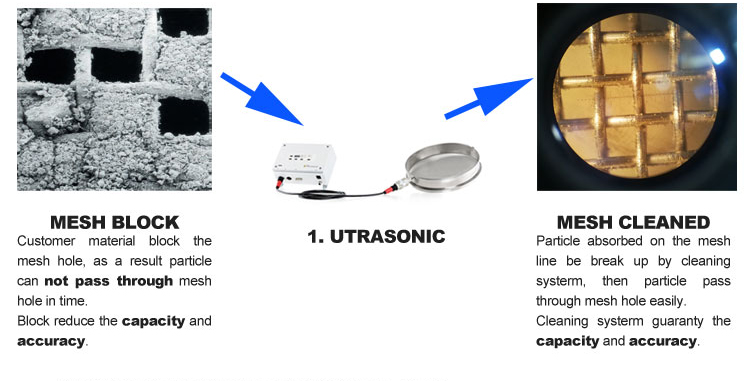

1. Fine particle size: Copper electrolytic powder can be very fine, which makes it difficult to separate particles of different sizes. Fine particles can also cause clogging of screening equipment, affecting process efficiency.

2. Agglomeration: Copper electrolytic powder is prone to agglomeration or agglomeration, which will affect the accuracy of the screening process. Agglomerated particles can also cause clogging of screening equipment.

3. Equipment wear and tear: The screening equipment used for copper electrolytic powder will wear out over time, which will affect the accuracy and efficiency of the process. This can lead to the need for regular maintenance and repairs to the equipment.

4. Pollution: Copper electrolytic powder is sensitive to contamination by foreign matter, which affects the quality of the final copper product. It is important to ensure that screening equipment is properly cleaned and maintained to prevent contamination.

5. Operator Safety: Handling copper electrolytic powder poses a health risk to the operator as the powder is dangerous if inhaled or ingested. Always follow proper safety procedures and use proper protective equipment when handling powder.

In general, with proper equipment and maintenance, as well as following proper safety procedures, the challenges faced in the copper electrolytic powder screening process can be overcome. Dahan Machinery has designed an ultrasonic sieving machine specifically for the copper electrolytic powder screening process. It can solve the above text encountered in the sieving of copper electrolytic powder.

Sieving Machine for Copper Electrolytic Powder

Copper Electrolytic Powder Sieving Machine

Ultrasonic sieving machine can be used to sieve copper electrolytic powders as they utilize high frequency ultrasonic vibrations to overcome some of the challenges associated with sieving fine powders. Some of the advantages of using ultrasonic sieving machine to screen copper electrolytic powder include:

1. Improve accuracy: Traditional sieving machines cannot achieve ideal product quality, because fine copper electrolytic powder adheres and clogs the screen, resulting in low flow rate and inconsistent product quality, and will also cause damage to the screen. Ultrasonic frequency vibration is used to vibrate the screen grid, high-frequency vibration helps break up agglomerated particles and prevents screening equipment from clogging, and makes it easier to screen powders with a separation accuracy as low as 20µm (#635 mesh)

2. Reduce wear and tear: Compared with traditional screening equipment, ultrasonic screening machines have less wear and tear, which can reduce maintenance costs and extend equipment life.

3. Increased throughput: Compared with traditional screening equipment, this ultrasonic sieving machine can increase the screening capacity by 10 times by eliminating mesh blockage.

4. Improved product quality: Ultrasonic vibrating sieves help to improve the quality of the resulting copper product by ensuring consistent size and quality of the powder used.

5. Safety: The closed system can be purged with inertia gas to isolate the pollution-sensitive powder from the ambient air and moisture, reduce the cross-contamination of the powder, eliminate the operator having to touch the powder, and ensure a safer environment

Overall, ultrasonic sieving machines are useful tools for sieving copper electrolytic powders, as they can overcome some of the challenges associated with sieving fine powders, resulting in a more efficient and accurate sieving process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.