Metal powder refers to a group of metal particles with a size of less than 1mm, including single metal powder, alloy powder and some refractory compound powder with metallic properties. It is the main raw material of powder metallurgy. , so the general vibrating screen is difficult to carry out effective screening, so it is recommended that you use a screening equipment specially designed to solve the difficult screening problems of materials such as light specific gravity, static electricity, sticking mesh, adsorption, agglomeration, and blocking mesh - ultrasonic vibrating screen . The specific reasons are as follows:

1. Screening of 100-mesh-600-mesh ultrafine materials

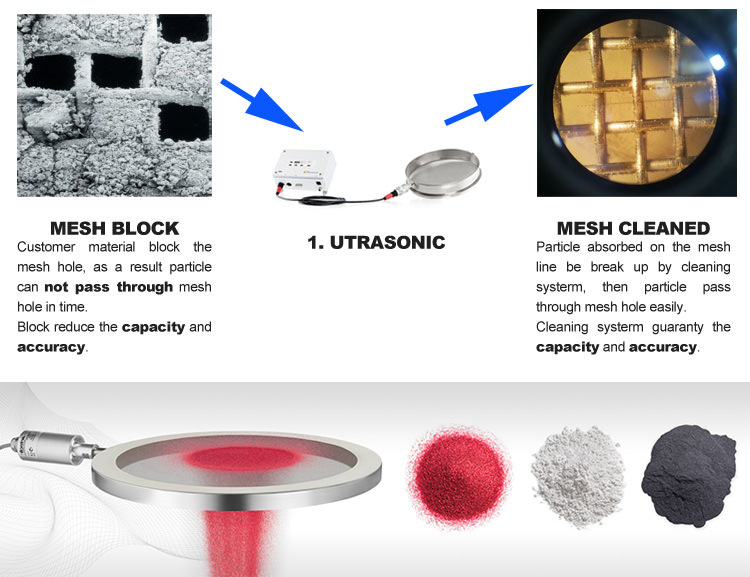

Metal powders can generate static electricity during sieving, causing particles to stick to sieves or other equipment, which can also lead to inconsistencies in the final product, and metal powders tend to agglomerate and particles stick together, which can make it difficult to sieve the powder and Obtain a consistent particle size distribution. In an ultrasonic vibrating screen, the transducer generates high-frequency vibrations and transmits them to the screen, these vibrations cause the metal powder to move in a circular or oval shape on the screen surface, which helps to prevent the powder from being trapped or sticking to the screen , while allowing separations down to 20µm (#635 mesh).

2. Fully enclosed structure, no dust

| Raw Material | Proportion | Mesh Size | Model | Method | Capacity |

| Graphite powder | 1.2 | 16/40/80 | DHC-1000-3S | Dry | 1400㎏/h |

| Lead powder | 11.34 | 10/80 | DHC-1000-2S | 1000㎏/h | |

| Tungsten carbide powder | 7.5-9.0 | 20-60 | DHC-800-2S | 400㎏/h | |

| Gold copper powder | 2 | 100 | DHC-800-1S | 70㎏/h | |

| Iron powder | 3 | 400 | DHC-800-1S | 230㎏/h | |

| Aluminum powder | 0.9/1.2 | 80/120 | DHC-800-2S | 350㎏/h | |

| Electrode powder | 0.95 | 20/200 | DHC-1000-2S | 550㎏/h | |

| Titanium dioxide | 2.1 | 16 | DHC-800-1S | 600㎏/h | |

| Manganese dioxide | 2 | 60 | DHC-1000-1S | 1550㎏/h | |

| Electrolytic copper powder | 1.5/2.4 | 24 | DHC-1000-1S | 210㎏/h |

Metal powder is flammable and explosive, and sieving will produce dust. If it is not properly controlled, there will be safety hazards. The closed system of the metal powder ultrasonic vibrating screen isolates the pollution-sensitive powder from the ambient air and moisture, reduces the cross-contamination of the powder, avoids the operator from contacting the powder, and ensures a safer environment. Oversized particles to increase the safety of handling metal powders.

3. The output can be increased by 2-15 times, and the screening efficiency is more efficient

Ultrasonic vibrating screen for metal powder is the core technology of ultrasonic power supply, which can improve the leveling and sliding effect of low-density powder in gravity sedimentation (light contact between powder and mesh port), and improve the retention or wedging of high-density metal in the mesh port. , to improve the adhesion effect of electrostatic powder, thereby improving the screening efficiency and screening quality. Compared with ordinary vibrating screen, the screening strength of ultrasonic vibrating screen can be increased by 2-100%, and the output can be increased by 2-15 times.

| Model | Test Material | Mesh Size | Test Results | |

| Vibrating Screen | Ultrasonic Vibrating Screen | |||

| φ1000 | Silicon carbide | 500 mesh | Cannot be sieved | 1500kg/h |

| φ1000 | Tungsten powder | 600 mesh | 15 minutes without sifting out fine powder | 30kg/h |

| φ1000 | Cobalt powder | 400 mesh | 10kg/h | 300kg/h |

| φ1000 | NdFeB powder | 300 mesh | 32.2% sieve residue in 30 minutes | 6.9% sieve residue in 30 minutes |

| φ1000 | Gold steel sand powder | 300 mesh | Cannot be sieved | 1300kg/h |

| φ1200 | Antimony trioxide | 80 mesh | 700kg/h | 2000kg/h |

The following is a comparison between ultrasonic vibrating screens and ordinary vibrating screens in screening different types of metal powders:

The ultrasonic vibrating screen used in the screening of metal powders can not only solve the problem of difficult screening of fine powders, but also expand production capacity for you, protect materials from pollution, achieve good screening results and improve screening efficiency for you!

Address:China,Yanjin county forest park gate to the west 1000 meters north road.