A powder coating sieving machine is an industrial device used to separate and classify powders according to particle size. It is commonly used in the powder coating industry to remove oversized or undersized particles from powder coatings before they are applied to a substrate.

The sieving machine is the key equipment in the powder coating process, which can ensure that the particle size of the powder coating is consistent, free of pollutants, and suitable for the application. The following are some specific applications of sieving machine in powder coating:

1. Remove oversized particles: The machine can remove oversized particles in powder coatings to ensure that the particles are small enough to adhere to the surface of the substrate to form a smooth and uniform finish.

2. Separation of fine particles: the fine particles in the powder coating can be separated to ensure that the particles in the powder coating are evenly distributed and will not agglomerate.

3. Removal of pollutants: dust, dirt and other impurities in powder coating materials can be removed to ensure high-quality and defect-free finished products.

4. Recycling of powder coatings: the sieving machine can be used to recycle the used powder coatings to ensure that the materials are pollution-free and suitable for repeated use.

While sieving is an important process in the production of powder coatings, some challenges can arise when using a sieving machine. Here are some common challenges faced when powder coatings are screened:

1. Agglomeration: Agglomeration occurs when powder coating particles stick together, forming clusters or clumps that are difficult to separate. This can lead to uneven particle size distribution and poor adhesion to the substrate.

2. Static electricity: Powder coating particles may become charged during sieving, causing them to stick to screens or other surfaces. This can lead to clogging of the sifter and poor particle separation.

3. Contamination: Powder coatings may be contaminated by foreign particles during the screening process, such as dust, dirt or other impurities. This may cause defects in the final product, reducing its quality and performance.

4. Screen wear: Over time, the screens in a screening machine wear down, resulting in less efficient and less accurate particle separation. This can lead to downtime and increased production costs.

5. Variation in particle size: Variation in particle size of powder coating materials can lead to uneven coating thickness and poor adhesion to the substrate, resulting in defects in the final product.

To overcome these challenges, it is important to use high-quality sieving machines, Ultrasonic Sieving Machines, designed for the specific requirements of the powder coating production process. Additionally, properly maintained and cleaned screens help reduce contamination and screen wear, ensuring consistent and high-quality particle separation.

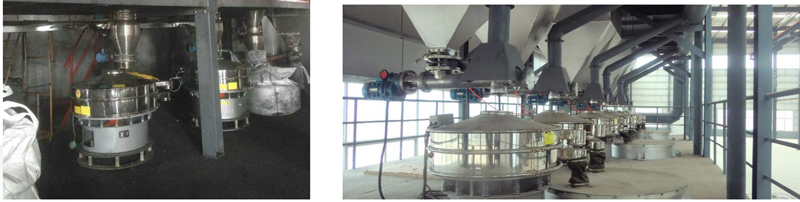

Ultrasonic sieving machines may be the best choice for sifting powder coatings for several reasons. Here are some key advantages of using an ultrasonic sieving machine to sieve powder coatings:

1. The high-frequency vibration of the ultrasonic system makes the powder coating in a low-altitude suspension state during the sieving process, which helps to reduce the blockage and blockage of the sieve, thereby improving the efficiency and accuracy of particle separation.

2. Automatic net cleaning can not afford static electricity, which may be a problem faced by traditional screening methods. Improve the screening output and greatly optimize the screening effect of powder coatings;

3. Compared with the expensive airflow sieve wind screening system, powder coating ultrasonic sieving machine is more cost-effective, with moderate output and lower space requirements.

Overall, the application of a sieving machine in powder coating is essential for ensuring that the powder coating material is of consistent quality and suitable for application, resulting in a high-quality and durable finish on the final product.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.