Polypropylene fiber belt conveyor is a common conveying equipment, which is mainly used to convey various granular, powdery and small lump materials, and is widely used in coal, electric power, metallurgy, chemical industry, food and other industries.

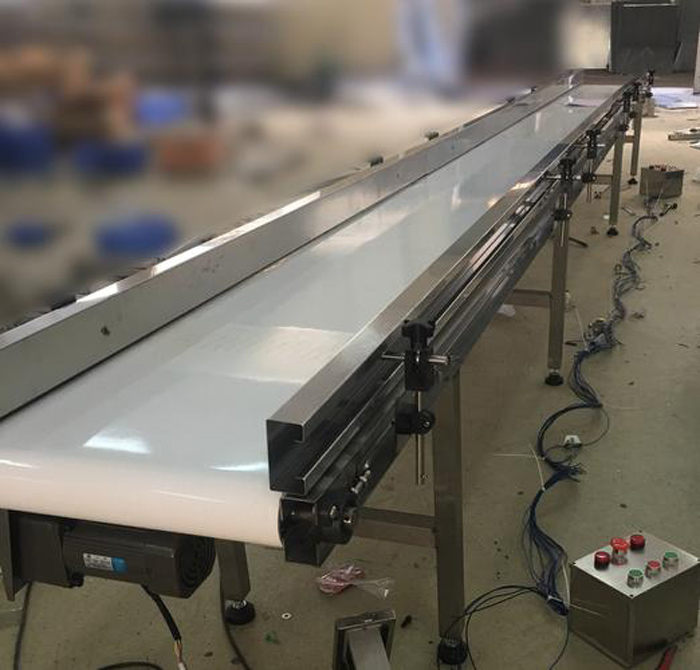

The polypropylene fiber belt conveyor is mainly composed of the following components: Polypropylene fiber belt: a conveyor belt made of polypropylene fiber, which has the characteristics of wear resistance and corrosion resistance, and is used to carry and transmit materials. Transmission device: including motor, reducer, etc., used to drive the operation of the belt. The motor transmits power to the belt through the reducer, so that it can carry out material transportation smoothly. Support structure: used to support and fix the main part of the conveyor, including conveyor brackets, supporting legs, etc.

The working principle of polypropylene fiber belt conveyor: Starting point loading: The material is loaded onto the polypropylene fiber belt from the starting point. Conveying process: start the transmission device, the motor drives the reducer, and the reducer drives the polypropylene fiber belt to start running. The belt moves over the support structure to transfer the material along the conveyor line to its destination. Unloading at the end point: After the material reaches the end point, it can be unloaded in different ways, such as gravity blanking, unloading hopper, etc. The polypropylene fiber belt conveyor is driven by the motor to make the polypropylene fiber belt move, so as to realize the transportation of materials.

Polypropylene fiber belt conveyor has the following characteristics: 1. Simple structure: Polypropylene fiber belt conveyor is composed of conveyor belt, roller, transmission device and support device, etc., with simple structure and easy installation and maintenance. 2. Large conveying capacity: The polypropylene fiber belt conveyor can be designed according to the flow requirements of the material, and the conveying capacity is large, which can meet the production needs of different scales. 3. Stable operation: The polypropylene fiber belt conveyor is made of high-quality polypropylene fiber, which has good strength and wear resistance, and can ensure long-term stable operation. 4. High transmission efficiency: The surface of the conveyor belt of the polypropylene fiber belt conveyor is smooth, and the friction between the material and the conveyor belt is small, which can reduce energy loss and improve transmission efficiency. 5. Environmental protection and energy saving: The transmission device used in the polypropylene fiber belt conveyor adopts frequency conversion speed regulation technology, which can adjust the conveying speed according to production needs, improve operating efficiency and reduce energy consumption.

Polypropylene fiber belt conveyors have a wide range of applications, and can be used for raw material transportation in cement plants, bulk material transportation in fertilizer plants, ore transportation in metallurgical plants, coal transportation in power plants, etc.

Food processing industry: Polypropylene fiber belt conveyors are often used to transport food raw materials, packaging materials, etc., because polypropylene fiber meets food safety standards, is easy to clean and corrosion-resistant.

Chemical industry: Polypropylene fiber belt conveyors can be used to transport chemical raw materials, liquids, powders and other materials. They are corrosion-resistant and wear-resistant and are suitable for a variety of chemical media.

Mining and metallurgical industry: Polypropylene fiber belt conveyors can be used to transport ore, slag and other materials, and their wear resistance can effectively extend their service life.

Building materials industry: Polypropylene fiber belt conveyors can be used to transport raw materials such as cement and sand and gravel, and their lightweight characteristics help reduce energy consumption.

Environmental protection industry: Polypropylene fiber belt conveyors can be used to transport waste materials, and have the advantages of corrosion resistance and easy cleaning.

Agricultural field: Polypropylene fiber belt conveyors can be used to transport grains, feed, etc., to help improve production efficiency.

When using polypropylene fiber belt conveyors, you need to pay attention to the following points:

Temperature control: The conveying temperature of the polypropylene fiber belt conveyor should be between -15°C and +40°C. Exceeding this range will affect the service life of the conveyor belt.

Maintenance: Regularly inspect and maintain the polypropylene fiber belt conveyor to maintain its normal operation. Remove debris on the conveyor belt, and regularly check the lubrication of the rollers and transmissions.

Prevent clogging: The materials on the conveyor belt should be kept evenly distributed to prevent accumulation and clogging, and avoid affecting normal operation. 4. Prevent overloading: the rated load of the polypropylene fiber belt conveyor must not be exceeded to avoid equipment damage or accidents caused by overloading.

To sum up, the polypropylene fiber belt conveyor is a simple, stable, efficient and energy-saving conveying equipment with broad application prospects. During use, pay attention to reasonable temperature control and regular maintenance to prevent blockage and overload.

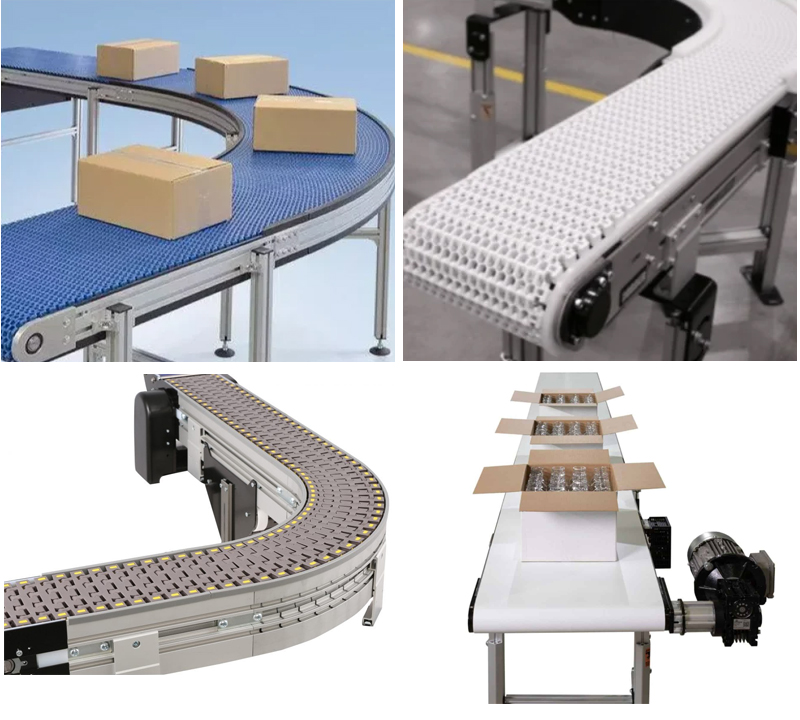

| Classification | Type | Features | Application industries |

| Weaving method | Plain woven conveyor belt | Tight structure, smooth and durable | Food, pharmaceutical, chemical |

| Weaving method | Mesh conveyor belt | Good air permeability, suitable for dry conveying | Fruit and vegetable cleaning, electronics industry |

| Structure | Single-layer conveyor belt | Lightweight, suitable for light-load conveying | Packaging line |

| Structure | Multi-layer conveyor belt | Strong load-bearing capacity | Mineral, industrial production |

| Structure | Modular conveyor belt | Easy to disassemble and maintain | Food, logistics conveying |

| Surface | Smooth conveyor belt | Smooth conveying, easy to clean | Medical, electronics |

| Surface | Anti-slip conveyor belt | Increase friction to prevent materials from sliding | Slope conveying |

| Surface | Breathable conveyor belt | Suitable for drying and cooling processes | Baking, printing and dyeing |

| Industry applications | Food-grade conveyor belt | Comply with FDA standards, safe and hygienic | Meat processing, fruit cleaning |

| Industry applications | Chemical-resistant conveyor belt | Acid and alkali resistant, corrosion-resistant | Pharmaceutical, sewage treatment |

| Industry applications | Antistatic conveyor belt | Antistatic, suitable for electronics industry | Electronic manufacturing |

| Industry applications | High-temperature resistant conveyor belt | Can be used in high temperature environments | Plastic products, baking |

Dahan Machinery Co., Ltd. can provide a full range of polyethylene (PE), polypropylene (PP) and polyoxymethylene (POM) modular conveyor belts, all standard materials are FDA approved for direct food contact.

Polyethylene: Can withstand operating temperatures as low as -73 °C, ideal for applications where a flexible belt material with excellent impact strength is required.

Polypropylene: Can withstand operating temperatures up to 100°C. It is a harder material with good tensile strength.

Polyoxymethylene: With an operating temperature range of -43 to +95°C, this material has great tensile strength and a hard surface that reduces friction for support and product.

Special Materials: Special materials are available to solve unusual tasks in high temperature areas, composite materials with reduced expansion, reinforced materials, conductive materials, non-stick materials, detectable polypropylene, flame retardant materials.

Accessories: Baffles in various heights and designs in the full range of products. Sidewalls in various heights. Top grip modular belts for inclined conveyors.

Please contact our customer service or send an email to sale@xxdahan.com and we will be happy to answer your questions.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.