Mechanical conveying system with belts made of PVC (polyvinyl chloride) as conveying medium.

![]()

![]()

Price:$980.00 - $7,800.00/Set

Consult now and enjoy a 10% discount

Belt material: food grade PVC

Belt width: 300-1500mm

Belt Type: Skirt

Speed: 0.8-4.0m/s

Conveying capacity: 28-800m³/h

Conveying length: 6 meters

Frame material: SUS304 stainless steel/carbon steel/aluminum

Weight: 300 kg

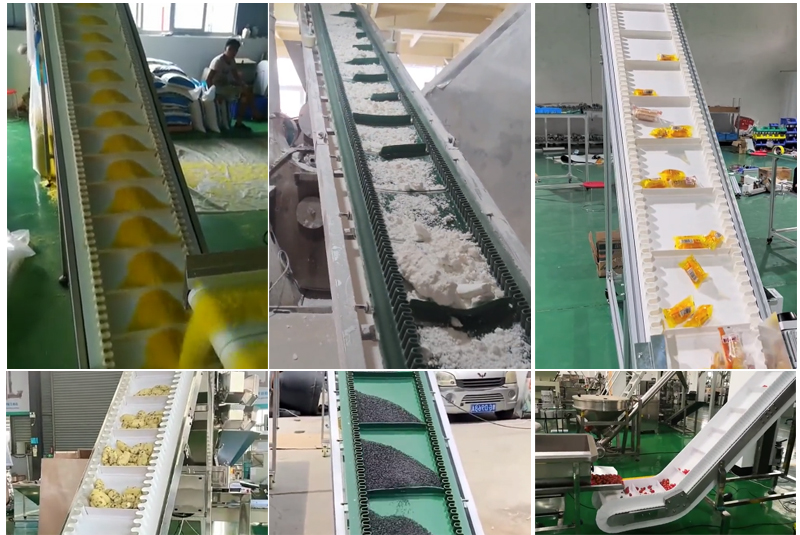

Application: Commonly used in manufacturing, packaging and logistics applications to move product along horizontal or inclined paths.

Commitment:

PVC belt conveyor is a type of mechanical conveyor system that uses a belt made of PVC (polyvinyl chloride) as the conveying medium. PVC belt conveyors are commonly used in manufacturing, packaging, and logistics applications to move products along a horizontal or inclined path.

PVC belt conveyors are commonly used in a variety of industries and applications for the handling and transportation of materials. Here are some examples:

Food Processing: Used in the food processing industry to convey food at various stages of production and packaging. They are designed to meet strict hygiene and safety standards and can be made from materials suitable for food contact.

Manufacturing: Transporting parts between workstations, assembly lines, and storage areas. They can be customized to suit different types of materials, including raw materials, finished products and heavy machinery.

Packaging: Often used in packaging applications to transport products along a production line. They can be designed to handle a wide variety of products including boxes, packaging and other materials.

Logistics: Used in logistics and distribution centers to move products between different stages of the supply chain. They can be used for truck loading, shipping packages and containers, and sorting delivered products.

Agriculture: Used to transport crops, seeds and other materials. They can be designed to handle a variety of materials including grain, hay and fertilizer.

The PVC belt conveyor is a continuous conveying equipment that uses the conveyor belt as a traction and bearing member to convey materials through the movement of the conveyor belt that carries the material. The conveyor belt is wound around the drive roller and the tail roller to form a carrier endless belt. The support is used to limit the deflection sag of the conveyor belt, and the tensioning device provides the necessary tension for the normal operation of the conveyor belt. When working, the drive device drives the drive roller, and the conveyor belt is driven by the friction between the drive roller and the conveyor belt. The material is loaded on the conveyor belt and moves together with the conveyor belt. The belt conveyor is generally unloaded at the end, and can also be unloaded in the middle when a special unloading device should be used.

Durability

PVC belt conveyors are constructed of durable PVC material and reinforced with polyester or other materials for added strength and durability. Belts are designed to withstand heavy loads and resist wear and tear.

easy to clean

PVC belts are easy to clean and sanitize, making them ideal for hygiene-conscious applications. The smooth surface of the PVC belt won't collect dirt and debris and is easy to wipe clean.

Versatility

Can be used to convey a variety of products including boxes, packages and other materials. They are available in various widths, lengths and load capacities to meet the specific requirements of different applications.

Customizable

PVC belt conveyors can be customized to accommodate different layouts and configurations, making them suitable for different production environments. They can be designed with curves, slopes and drops to meet the specific needs of the application.

Run quietly

Quiet and smooth operation, ideal for applications where noise is a concern.

Cost-effective

PVC belt conveyors are usually less expensive than other types of conveyors.

PVC (Polyvinyl Chloride) and PV (Polyester Vinyl) are two types of synthetic materials that are commonly used to make conveyor belts. Here are some differences between PVC and PV conveyor belts:

| Compared | PVC Conveyor Belt | PU Conveyor Belt |

| Material | Made of PVC material | Made from a combination of polyester and vinyl |

| Strength | Not as durable as PU material | PU belts are generally stronger than PVC belts due to the polyester reinforcement. This makes photovoltaic conveyor belts more suitable for heavy-duty applications that require high strength and durability. |

| Flexibility | Typically more flexible than PU conveyor belts, which can make them better suited for applications that require the belt to bend or bend. | Usually less flexible than PVC conveyor belts |

| Temperature resistance | Limited to temperatures around 60°C | Higher temperature resistance, can withstand temperatures up to 200°C |

| Chemical resistance | PVC conveyor belts are more acid resistant | More resistant to alkaline solutions |

| Cost | Cheaper than PU conveyor belts | High cost |

| Belt width (mm) |

Conveying length(m) Power(kw) |

Conveying speed (m/s) |

Conveying amount (t/h) |

||

| B400 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 30-60 |

| 3 | 3-4 | 4-7.5 | |||

| B500 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 40-80 |

| 3 | 4-5.5 | 5.5-7.5 | |||

| B650 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 80-120 |

| 4 | 7.5 | 7.5-11 | |||

| B800 | ≤10 | 12-15 | 15-30 | 1.25-2.0 | 120-200 |

| 4 | 7.5 | 7.5-15 | |||

| B1000 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 200-320 |

| 5.5 | 7.5-11 | 11-22 | |||

| B1200 | ≤10 | 10-20 | 20-40 | 1.25-2.0 | 290-480 |

| 7.5 | 7.5-15 | 15-30 | |||

| B1400 | ≤10 | 10-20 | <20-40 | 1.25-2.0 | 400-680 |

| 11 | 15-22 | 22-45 | |||

| B1600 | ≤10 | 10-20 | <20-50 | 1.25-2.0 | 600-1080 |

| 15 | 22-30 | 30-75 | |||

| B1800 | ≤10 | 10-20 | <20-50 | 1.0-2.0 | 200-1500 |

| 18.5 | 30-45 | 45-110 | |||

| B2000 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1000-2000 |

| 22 | 45-55 | 55-132 | |||

| B2400 | ≤10 | 10-20 | <20-40 | 1.0-2.0 | 1500-3000 |

1. Basic dimensions: the length, width and height of the equipment, the climbing angle for climbing, the turning radius for turning, etc.

2. Frame material: carbon steel spray/stainless steel/aluminum, usually choose carbon steel spray.

3. Conveying speed: V≤60 m/min, common speed is 3-~15m/min.

4. Conveyor belt: green PVC material is selected by default, whether to add baffles and skirts

5. Motor power: 0.2/0.4/0.75/1.5/2.2/3.7kw.

6. Power supply: AC220V/AC380V.

7. Diameter of driving roller: 38, 50, 76, 89, 120mm and so on.

8. Other accessories: whether to install guardrails on both sides, whether it is mobile, whether the speed is adjustable, whether it has lifting and lowering, other requirements, etc.

WhatsApp:+86 15236742901

Address::China,Yanjin county forest park gate to the west 1000 meters north road.