It is very effective to meet the screening, impurity removal and filtration of production PH value and corrosive materials

![]()

![]()

![]()

Price:$500.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Material: PP polypropylene or PE

Diameter: 400/800/1000/1200/1500/1800/2000 mm

Mesh size: 2-500 mesh

Capacity: 1100-3300kg/h

Layers: 11-5 layers

Voltage: 1220/380V Power: 0.18-2.2kw

Application: It is used in the field of strong acid and alkali materials such as phosphor, iron powder, copper sulfate, chemical raw materials, disinfectants, aluminum trichloride, or chemical preparations that cannot be in contact with metals.

Commitment:

Plastic vibrating screen is also called polypropylene vibrating screen. It is made of PP polypropylene or PE material. It is specially used for screening and filtering corrosive materials or slurry. It can solve the oxidation and corrosion problems of ordinary steel when screening some chemical raw materials, such as some special materials such as sulfuric acid materials, disinfection agent, copper sulfate, phosphorus, etc., and can ensure that the material will not deteriorate during the screening process.

The screen and screen frame of the plastic vibrating screen are all made of polypropylene material, which solves the screening, impurity removal and filtration of materials with oxidized and corroded steel materials, and ensures that the materials will not deteriorate during the screening process.

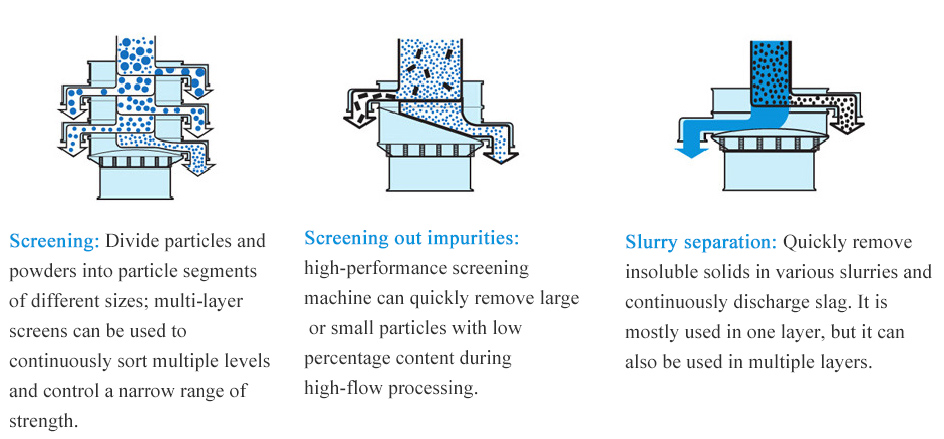

1. Screening: Divide the solid particles into different particle groups of equal size. A single unit can be equipped with 1-5 layers of screens, which can accurately and continuously classify 2-6 particle segments at the same time. The classification accuracy is over 95%.

2. Impurity removal: High-precision screen can quickly remove large or small particles with low percentage content in the process of high-flow material processing, mostly single-layer use. The plastic vibrating screen has high efficiency in removing impurities, and the accuracy can reach more than 98%.

3. Slurry filtration: It can quickly remove the insoluble large particles in all kinds of slurries, and most of them are used in a single layer. The specially designed screening filter can filter up to 20 cubic meters per hour.

In some screening cases, especially in the chemical industry, some special materials such as sulfuric acid materials, disinfectants, copper sulfate, phosphorus, etc., will cause oxidation and corrosion problems to Q235 ordinary carbon steel and SUS304 stainless steel. In order to solve this problem, Dahan Machinery has developed a plastic vibrating screen, which is made of pp plastic material, which can solve the problems of sieving, removing impurities and filtering materials due to oxidation and corrosion of steel, and can ensure that materials will not deteriorate in the screen.

Application products: fluorescent powder, paint, PVC resin powder, citric acid, resin powder, polyethylene powder, washing powder, etc.

The following table shows the application of plastic vibrating screens in chemical raw materials:

| Production | proportion | Mesh Size | Model | Method | Capacity (kg/hr T/hr) |

| Epoxy resin | 1.8 | 100 | SLS-1000-1S | dry | 280㎏ |

| MBS resin | 0.3 | 30 | SLS-800-1S | 350㎏ | |

| Melamine resin | 0.4 | 30/60 | SLS-600-2S | 36㎏ | |

| PVC resin | 1 | 10㎜/5㎜ | SLS-1200-2S | 3000㎏ | |

| Polyethylene powder | 0.45 | 48/100 | SLS-800-2S | 100㎏ | |

| Polyethylene resin | 0.5 | 60 | SLS-1000-1S | 450㎏ | |

| Spray paint | 1.1/1.2 | 325 | SLS-600 | wet | 600T |

| Epoxy powder coating | 5.0/0.8 | 80 | SLS-800-1S | dry | 450㎏ |

| Polyester powder coating | 0.6/0.8 | 100 | SLS-1000-2S | dry | 400㎏ |

Plastic vibrating screen for ceramic powder

Plastic vibrating screen for sodium hydroxide powder

Acid and alkali corrosion resistance

Polypropylene material, with good chemical stability, is often suitable for screening and filtration of corrosive materials, such as phosphor powder, chemical powder, copper sulfate, etc.

Heat resistance

It has good heat resistance, the melting point is 164 to 170 degrees, and the products can be sterilized at temperatures above 100 degrees, and will not deform at 150 degrees without external force.

Multi-layer grading

It can be used with single-layer or multi-layer screen mesh, and can carry out 2-4 grade filtration at the same time.

Light weight

Plastic material, light weight, easy to move, the discharge port can be adjusted 360 degrees.

High efficiency

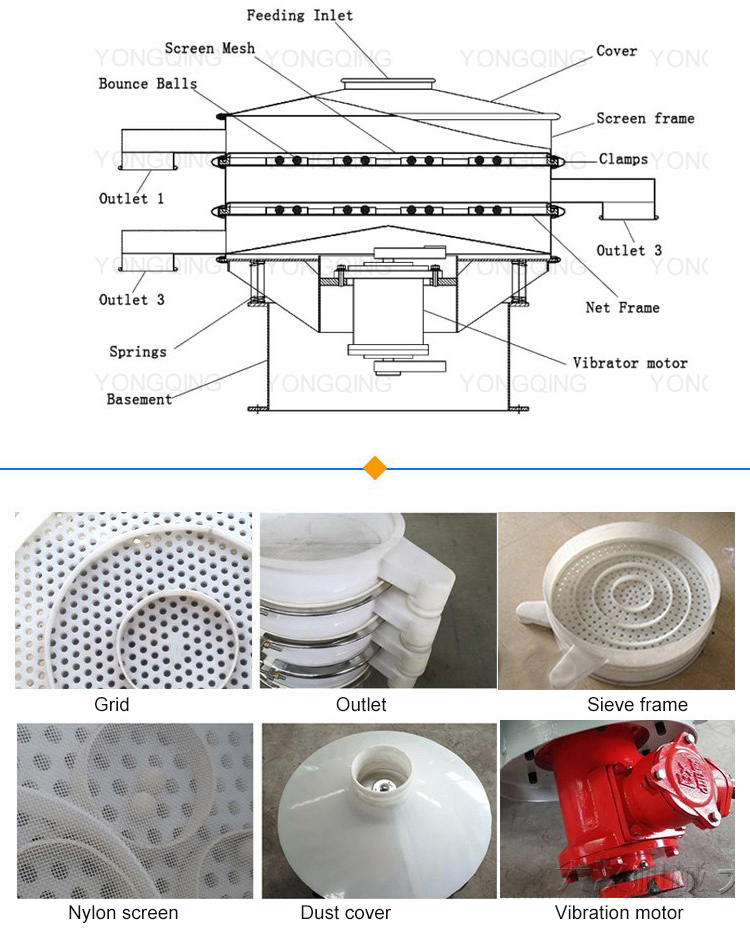

It can sieve powder, granule and filter liquid. The filtering capacity can be as high as 20 cubic meters per hour, and the screening capacity can reach 100-2000 kg per hour. The bouncing ball cleaning device can continuously impact the screen through frequency vibration, so that the material can pass through the screen smoothly without blocking the screen, and the screening efficiency is high.

Long lasting

Polypropylene will have low losses under vibration compared to other materials. For example, the wear of carbon steel materials will wear out with the up and down vibration of the vibration motor, while polypropylene screen mesh, with a density of 0.90g/cm3, is a lighter general-purpose plastic, so it has less gravity than carbon steel, so it wears more. Low. Therefore, it has a longer lifespan.

| Model | Power | Sieve diameter | Number of | Granularity | Voltage | RPM | Throughput |

| (kw) | (mm) | Layers | (mm) | (V) | (r/min) | (kg/h) | |

| (layer) | |||||||

| SLS-400 | 0.18 | 350 | 1-4 | <10 | 380 | 1440 | 100 |

| SLS-600 | 0.25 | 550 | 300-500 | ||||

| SLS-800 | 0.55 | 750 | 500-800 | ||||

| SLS-1000 | 0.75 | 920 | 900-1400 | ||||

| SLS-1200 | 1.1 | 1120 | 1500-2100 | ||||

| SLS-1500 | 1.5 | 1420 | 2100-2600 | ||||

| SLS-1800 | 2.2 | 1720 | 2600-3300 |

Material: chemical powder

Mesh: 20 mesh

Output: 4-5 tons/day

Configuration equipment: 1200mm plastic vibrating screen

Material: Disinfectant

Mesh: 30 mesh

Output: 2-3 tons/hour

Configuration equipment: 1500mm diameter plastic vibrating screen

Material: copper sulfate (specific gravity 0.7)

Mesh: 18-20 mesh

Output: 1 ton/hour (30% of the sieve)

Configuration equipment: recommended 1000mm plastic vibrating screen

Material: alumina powder

Mesh: 140 mesh

Output: 1000kg/hour

Configuration equipment: 800mm single-layer plastic vibrating screen

Dahan plastic vibrating screen models have 7 specifications such as 400-2000mm, can be installed with 1-6 layers of screen mesh, support customization (feeding hopper, feeding bin, bottom barrel height, etc.), the production equipment is made of polypropylene PP material, screen mesh It is made of nylon material, which is resistant to acid and alkali corrosion, which can solve the problems of oxidation and corrosion caused by contact with carbon steel/stainless steel materials when some special materials are screened.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.