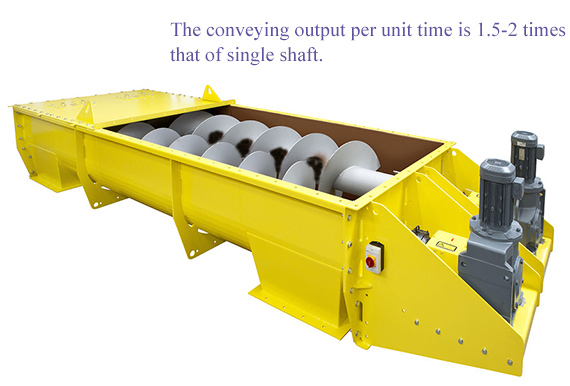

As the name suggests, the double shaftless screw conveyor is a conveying machine composed of two shaftless screw conveyors. The lead angle (or helix angle) of the double shaftless screw conveyor blade is higher than that of the single screw blade, and its conveying capacity Also bigger (1.5-2 times).

Like the single shaftless screw conveyor, the double shaftless screw conveyor is also suitable for conveying materials with high viscosity and easy winding, but compared with the single shaft, the double shaftless screw conveyor can perfectly complete the material mixing and Stir well and work loosely.

Manganese steel material: conveying materials such as stones and other abrasive materials

Stainless steel material: conveying food and medical materials

Carbon steel material: conveying general materials

The double shaftless screw conveyor is mainly used for conveying viscous and easy-to-wind materials, such as garbage, cement, white ash and other materials. layout.

1. No central shaft design, anti-winding, can prevent the material from clogging during the conveying process.

2. Double-blade structure, the conveying output per unit time is 1.5-2 times that of single shaft.

3. The double shaft design can complete the mixing and loosening of the material while conveying the material, and crush the agglomerated material.

4. The fully enclosed design structure can reduce dust phenomenon, reduce environmental pollution, and prevent material leakage.

5. The inside of the pipe groove is made of wear-resistant lining plate made of rubber plate or cast stone plate, which has a long service life.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.