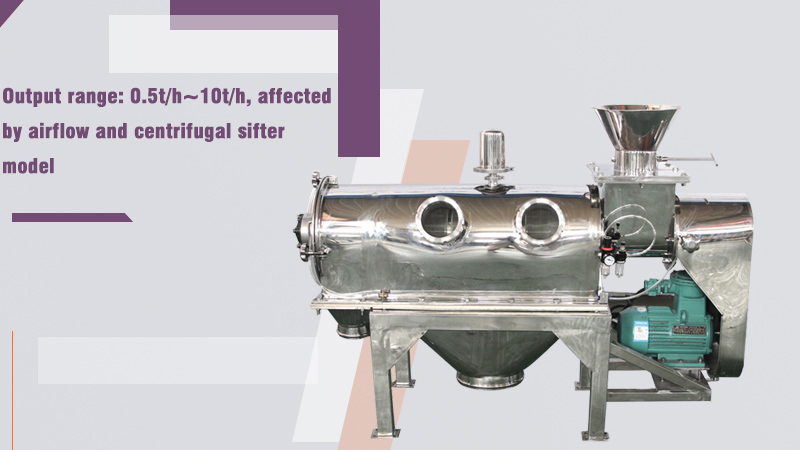

Centrifugal sifter is usually also called centrifugal sifter by us. It is a fine sieve machine that sieves by wind airflow. It is extremely suitable for sieving fine powder materials with good fluidity, small and light weight, and is also widely used:

1. Fineness range: 80 mesh ~ 600 mesh (0.023mm), coarse granular materials are not screened

2. Output range: 0.5t/h~10t/h, affected by airflow and centrifugal sifter model

Chemical industry - soda ash, plastic particles (fine powder), additives, paints, pigments, rubber powder, coatings, etc.

Non-metallic industry - carbon black (silica), quartz powder, mica, phosphor, fly ash, glass beads, etc.

Metallurgical industry - alloy powder, (gold, silver, copper, aluminum, nickel, zinc) powder, foundry sand, etc.

Food industry one (rice, noodles, milk) - powder, starch, hawthorn powder, etc.

Pharmaceutical industry - Western medicine powder, traditional Chinese medicine powder, pharmaceutical intermediates, pearl powder, etc.

Other industries - environmental protection, plastics, magnetic materials, mining, kiln industry, etc.

| Materiel | MESH | Output(kg/h) |

| Light calcium powder | 120-180 | 600 |

| Heavy calcium powder | 400 | 800 |

| starch | 300 | 500 |

| zinc powder | 325 | 900 |

| flyash | 120-200 | 364 |

| powder | 120-160 | 1000 |

| quartz flour | 180-270 | 1280 |

| wood flour | 100-300 | 2000 |

| mica flour | 300-400 | 1500 |

| Hawthorn powder | 200-300 | 1000 |

| iron oxide black | 450-520 | 900 |

(It is tested for medium-sized centrifugal sifters, the output of different models is different, for reference use)

1. The centrifugal sifter is extremely suitable for sieving small and light powder materials with good fluidity, and can produce a good screening effect on extremely fine materials as fine as 600 mesh (0.023mm);

2. Using the wind force as the screening power will blow away the materials adhering to the screen without blocking the screen;

3. The agglomerated material can be re-crushed;

4. Since the centrifugal sifter is a wind screen, it cannot screen large, heavy and easily sticking materials;

5. The output is large and the screening efficiency is high, which can reach more than 95%, and the output is 5-10 times or higher than that of the vibrating screen.

6. It can be used with single machine or multiple machines, and it can run continuously for a long time, which is safe and reliable;

7. Fully enclosed design, dust is not easy to escape;

8. Low noise, low power consumption, continuous operation and convenient maintenance.

As an important granular material screening equipment, centrifugal sifter plays an important role in industrial production. Our manufacturer produces different models of centrifugal sifters for a wide range of applications. If you are interested in centrifugal sifters, you can click on our online chat to inquire, and I will provide you with the best solution and best quotation.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.