The centrifugal sifter is a kind of screening machine that uses wind as the power to screen small and light fine powder materials. The common centrifugal sifters we see can be divided into two types: vertical centrifugal sifter and horizontal centrifugal sifter, then What's the difference between them? Find out today:

In principle, there is little difference between the horizontal centrifugal sifter and the vertical centrifugal sifter. Their differences are mainly reflected in product performance,

screening capacity, etc.

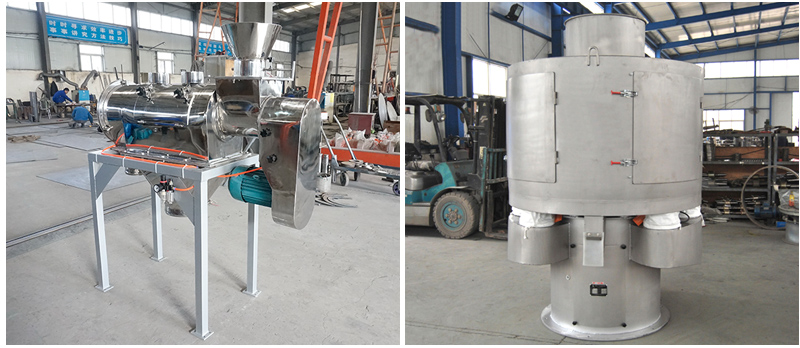

1. In terms of appearance, the screen box of the vertical screening machine is installed vertically, and the screen box of the horizontal screening machine is installed horizontally;

2. The screening accuracy of the vertical centrifugal sifter is higher than that of the horizontal centrifugal sifter:

Horizontal centrifugal sifter: the sieving mesh number is below 500 mesh, and the power is 2.2-5.5kw.

Vertical centrifugal sifter: sieving mesh 80-600 mesh, power 3-15kw.

3. Different applications:

The wind generated by the vertical centrifugal sifter will be stronger than that of the horizontal centrifugal sifter. Relatively speaking, the vertical centrifugal sifter is more suitable for large-scale industrial screening;

The vertical centrifugal sifter requires 90% or more of the fine materials in the raw materials to be screened, which is suitable for fine powder screening; while the horizontal centrifugal sifter can be used to screen materials with more coarse powders.

4. Screening form:

The vertical centrifugal sifter mixes the material with the air through the negative pressure airflow and then enters the middle of the sieve rotor, and exerts sufficient centrifugal force through the blades of the rotor to spray through the screen like a barrel screen;

The horizontal centrifugal sifter is that after the material passes through the screw conveying system, it is mixed with the airflow and atomized into the mesh cylinder, and the material is simultaneously driven by centrifugal force and cyclone through the wind rotor blades in the mesh cylinder, thereby forcing the material to spray through the mesh.

5. Each has its own advantages

Horizontal centrifugal sifter: With the latest design, the gas protection system can transport the purified air to the centrifugal sifter, effectively reducing the temperature generated by the centrifugal sifter during operation; it forms a gas isolation layer on the bearing to isolate the dust pollution, Extend bearing life, reduce maintenance frequency and improve work efficiency

Vertical centrifugal sifter: high screening accuracy, no super mixing phenomenon; vertical installation of the screen, long service life without load; operation under negative pressure semi-circulation, no need to worry about dust pollution.

6. Model

Horizontal centrifugal sifter: WSA18-65, WSA30-100, WSA50-130, different models mean different sizes.

Vertical centrifugal sifter: WS-600, WS-1000, WS-1000, the model is defined by the diameter of the vertical centrifugal sifter.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.