Quicklime is a common inorganic chemical substance with a wide range of applications. Quicklime is also an important construction material, used to prepare limestone slurry, limestone cement, etc. In the production process, in order to ensure product quality and use effect, quicklime particles need to be screened and classified. This is where the vibrating screen comes into play.

The quicklime particle vibrating screen is a kind of high-efficiency screening equipment, which uses a vibration excitation source to vibrate the screen surface to make the particles move and separate on the screen surface. Due to the certain adhesion and wetness of quicklime particles, conventional screens are easy to block and stick, resulting in poor screening effect. The vibrating screen has the characteristics of adjustable vibration frequency and amplitude, which can effectively solve this problem.

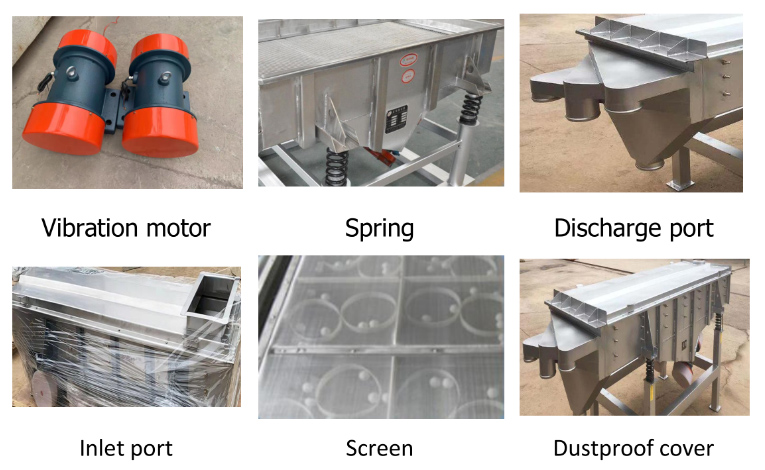

The main components of quicklime vibrating screen include casing, screen box, vibrator and screen. The casing is the shell that supports and protects the equipment, the screen box is the area where the screen is installed and the particles are separated, the vibrator is a device that provides vibration force, and the screen is the part used to screen and separate particles.

The working principle of quicklime particle vibrating screen is to make the vibrator generate continuous vibration through the vibration excitation source, and then the vibrator transmits the vibration to the screen box and screen mesh through the connecting piece. The particles in the sieve box are affected by the vibration force, resulting in continuous beating and friction, so as to achieve the purpose of screening and separation. The vibrating screen has the characteristics of high frequency vibration and large amplitude, which can effectively improve the screening effect and processing capacity.

Quicklime particle vibrating screen has many advantages. First of all, the vibrating screen has a high-efficiency screening effect, which can realize high-quality screening and classification of quicklime particles. Secondly, the vibrating screen has a self-cleaning function, which can prevent the clogging and bonding of the screen and improve the continuous operation time of the equipment. In addition, the vibrating screen also has the characteristics of simple structure and easy operation, easy maintenance and cleaning, reducing production costs and labor costs.

In practical application, quicklime particle vibrating screen is widely used in construction materials, chemical industry, metallurgy, mining, electric power and other fields. Through reasonable vibration frequency and amplitude adjustment, it can meet the screening requirements of different particle sizes and improve product quality and production efficiency. In addition, the vibrating screen can also be used in conjunction with other equipment to form an automated production line to improve production efficiency and reduce labor intensity.

To sum up, quicklime particle vibrating screen is a very important and commonly used screening equipment, which has the advantages of high efficiency, high quality and automation, and is widely used in various industries. With the continuous development and progress of science and technology, the performance and application of quicklime particle vibrating screen will also be continuously improved and innovated.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.