Glass fiber horizontal airflow screen is a device commonly used for fine powder classification and screening. It is usually used to process materials with small particle size and easy to be carried away by airflow. It is especially suitable for glass fiber, powder coating, chemical raw materials and other industries. It classifies and screens materials through the action of airflow, and has an efficient and fine screening effect.

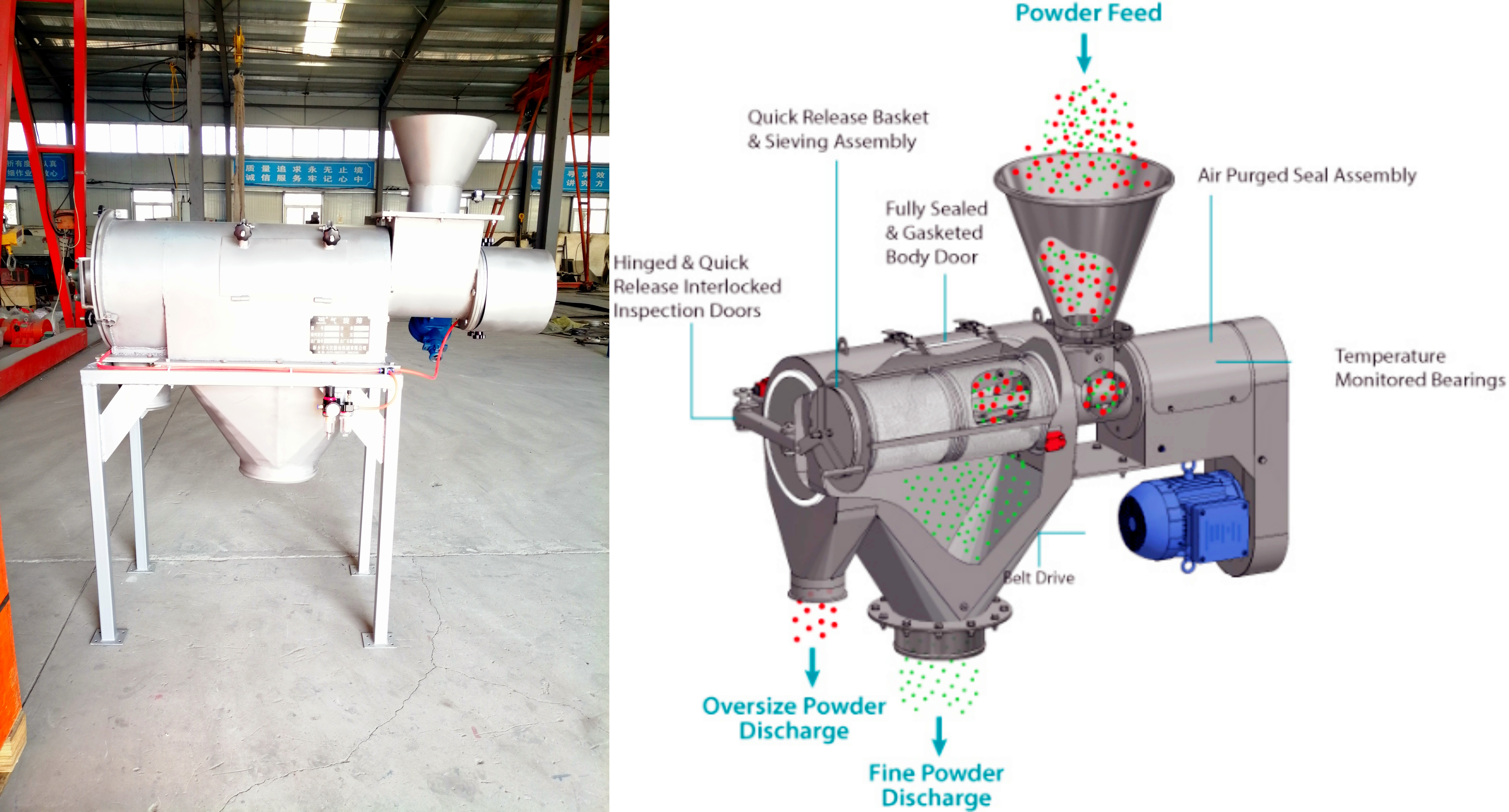

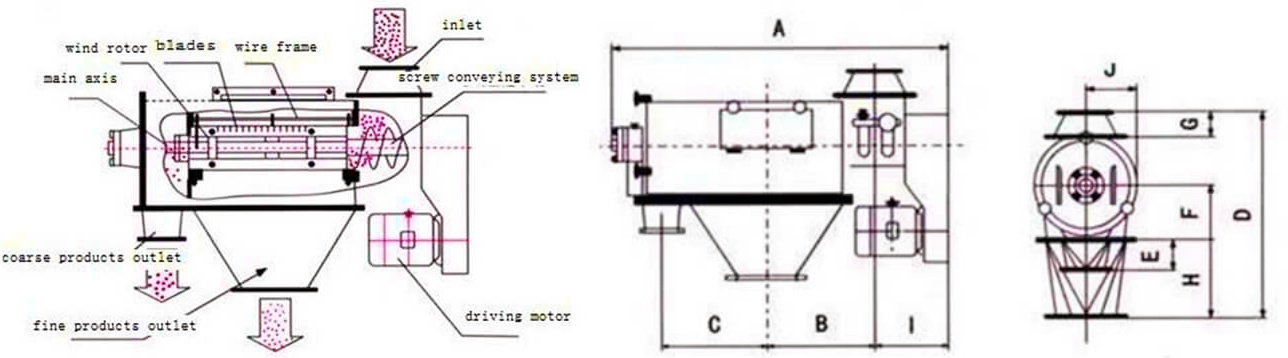

Material conveying and mixing: glass fiber material enters the equipment through the spiral conveying system, is suspended under the action of high-speed airflow, fully mixed and atomized with the airflow, and forms a uniform gas-solid mixture.

Centrifugal and propulsion action: the gas-solid mixture enters the cylindrical screen, and the wind wheel blades in the screen rotate at high speed, so that the material is subjected to centrifugal force and cyclone propulsion force at the same time. Under the combined action of these two forces, the material is accelerated and ejected toward the screen.

Screening and separation: material classification is carried out through the combined action of airflow and screen. When the glass fiber is fed into the screen machine, the airflow pushes the fine glass fiber particles through the screen through the screen, and the larger particles are blocked on the surface of the screen. The airflow can control the screening accuracy by adjusting the flow rate, thereby achieving the separation of glass fibers of different particle sizes.

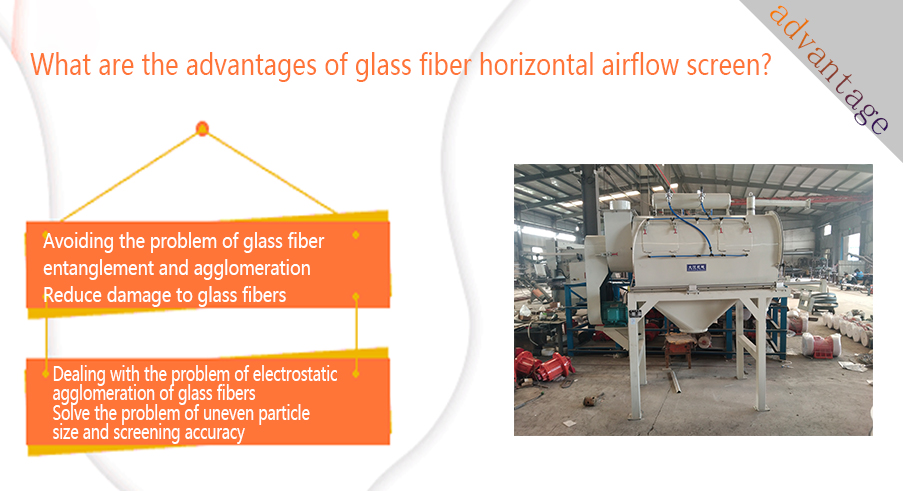

Avoiding the problem of glass fiber entanglement and agglomeration: There is a high-speed rotating blade or rotor inside the horizontal airflow screen. When the material enters the screen drum, the rotor exerts mechanical impact and stirring effects on it, effectively breaking up the entangled fiber clumps and presenting them to the screen in a more dispersed state. The airflow entering the screen drum also helps to disperse the material and reduce the entanglement between fibers.

Reduce damage to glass fibers: Compared with traditional screening equipment that relies on strong vibrations, the glass fiber horizontal airflow screen mainly relies on airflow and relatively gentle mechanical sweeping for screening. The design and speed of the rotor can be optimized to minimize damage to the length and structure of the glass fiber while ensuring screening efficiency.

Dealing with the problem of electrostatic agglomeration of glass fibers: Due to its low density and fibrous structure, glass fiber is prone to generate static electricity due to friction during transportation, causing the material to agglomerate or adhere to the surface of the conveying pipe, screen, etc. The horizontal airflow screen uses high-speed airflow as a carrier. When the material enters the screen, it is mixed and atomized with the airflow, and the strong airflow effectively breaks up the agglomerated fibers or powders.

Solve the problem of uneven particle size and screening accuracy: glass fiber raw materials, chopped strands or fillers may be unevenly mixed or agglomerated during transportation, resulting in uneven particle size distribution, affecting the quality of downstream processes. The glass fiber horizontal airflow screen uses centrifugal force and cyclone propulsion to fully disperse the material in the mesh cylinder, fine particles pass through the screen, and coarse particles are discharged along the wall of the mesh cylinder. The screening accuracy can reach more than 95%.

Coarse screen (30 mesh-80 mesh): Glass fiber horizontal airflow screen is suitable for screening of large particles of glass fiber, mainly for coarse screening and preliminary screening.

Medium screen (80 mesh-200 mesh): Suitable for screening of medium-sized glass fibers. This range is suitable for screening requirements of subdivided materials.

Fine screen (200 mesh-400 mesh): Used to screen finer glass fiber particles, suitable for application scenarios requiring high screening accuracy and purity.

1. Production and processing of glass fiber

In the production process of glass fiber, the raw materials are often broken glass, sand and other minerals, and the particle sizes of these raw materials are uneven. In the process of producing glass fiber, the horizontal airflow screen can effectively screen these raw materials to ensure that the particle size of various materials meets the production requirements and ensure the quality and stability of the product.

2. Surface treatment of glass fiber

In the surface treatment process of glass fiber, it is often necessary to process its surface coating. The horizontal airflow screen can remove surface impurities and excess particles to ensure the smooth surface of the glass fiber and avoid the uneven surface or attachments that affect its subsequent processing and application.

3. Grading of powdered glass fiber materials

In the manufacturing process of glass fiber powder, horizontal airflow screens are used to grade glass fiber powders of different particle sizes. For example, when producing fine glass fiber powder, the screener can help screen out coarse particles that do not meet the requirements, thereby improving the accuracy and uniformity of the product.

4. Production of glass fiber composite materials

Glass fiber is often combined with other materials such as resins and plastics to form composite materials, which are usually used in construction, automobiles, ships and other industries. Airflow screens can effectively separate fine particles in glass fiber to ensure the quality of composite materials. Especially when producing high-quality composite materials, it is crucial to keep the particle size of glass fiber uniform.

The selection of glass fiber horizontal airflow screen is usually based on the particle size requirements, output requirements and required screening accuracy of the material. In terms of price, due to its efficient screening function and complex structure, it is usually more expensive than traditional screening equipment. The specific price needs to be determined according to the specifications, manufacturers and technical requirements of the equipment.

If you need more detailed technical parameters or selection suggestions about the equipment, you can consult according to specific needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.