Sand screening machine

Sand screening machine Multi-layer sand screening machine

Multi-layer sand screening machine Inline sand screening machine

Inline sand screening machine Quartz sand screening machine

Quartz sand screening machine Casting sand screening machine

Casting sand screening machine

Before batching, the sand needs to be classified according to the particle size, and then batched according to the production requirements.

![]()

![]()

![]()

Price:$900.00-$6,500.00/Set

For screening sand for construction work

Function: Divide the sand into coarse, medium and fine grades of sand for batching.

Mesh size: 5-200 mesh

Granularity size: 0.074-60mm

Capacity: 2-30t/h

Layer: 1-6 Layers

Motor: 0.75*2kw, 380V, 50Hz, 960rpm

Application: fine-grained to medium-grained sand such as quartz sand, river sand, yellow sand, mullite sand, machine-made sand, etc.

Commitment:

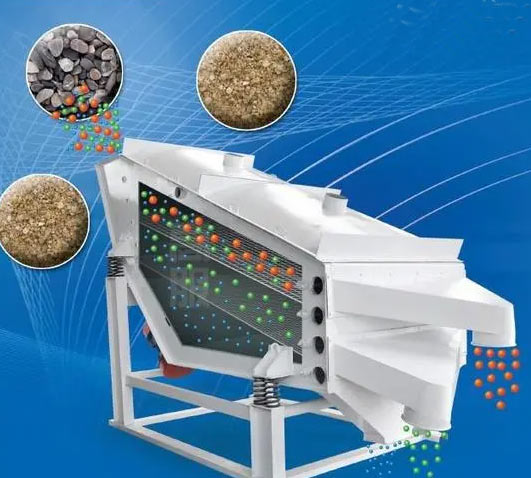

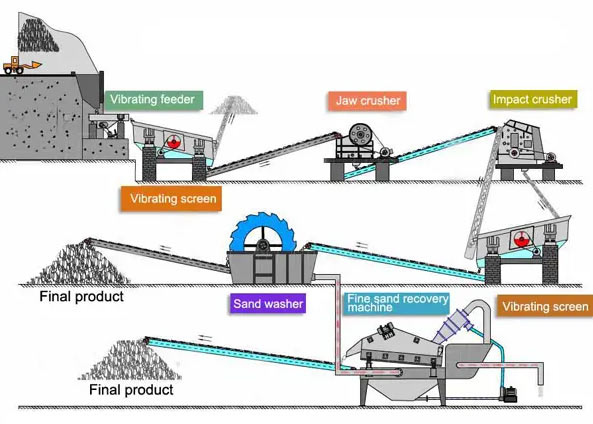

Sand screening machine is also called vibrating sand screening machine. After the sand is crushed, the coarse particles larger than 5mm need to be removed first, and then the sand is divided into coarse, medium and fine sand with different particle size grades for batching. In the process of designing sand and gravel production lines, the output of the industry is generally relatively large, and an ordinary single vibrating screen cannot meet its high output requirements, which can only be achieved with multiple sets. 4-6 screening equipment, even a small sand and gravel production line requires at least two vibrating screen equipment.

Sand screening machine can not only be used for grading and screening of finished sand and gravel, but also can be used to screen the materials crushed by primary crushing equipment and secondary crushing equipment. The screening is distinguished, and the belt conveyor can be connected with the host equipment to form a closed loop. In the sand and gravel production line, multi-layer vibrating sand screening machines are generally used in parallel operation, which can screen the materials at one time, save a lot of production time, and meet the needs of the finished aggregate particle shape.

Sand screening machine can not only be used for classification and screening of finished sand and gravel, but also for screening materials crushed by primary crushing equipment and secondary crushing equipment.

Typical applications: used for separation of sand and gravel in sand and gravel yard, used for grading of large and small stones in stone quarry, and separation of soil and stone powder.

1. Classification of finished materials

When it comes to screening, the most common thing is the screening of finished sand and gravel aggregates at the end. A production line processes more than one kind of finished aggregate, and different users have different requirements for the granularity of sand and gravel aggregates, so they are screened Products of various particle sizes are supplied to various users, which is called independent screening.

2. Pre-screening

Sometimes it is necessary to screen before crushing. For example, the particle size range of raw materials is relatively large, and large pieces of materials need to be roughly broken by jaw crusher first, while small pieces of materials can be directly screened and then sent to subsequent equipment in order to avoid over-crushing. No need to re-jaw break. The screening at this time is called pre-screening.

For sand and gravel processing plants, pre-screening can avoid ineffective crushing of materials, thereby improving the production capacity of crushing equipment and reducing power consumption. Leakage type feeder or special vibrating screen are ideal pre-screening equipment.

3. Check and screen

Many production lines also add a screening process after crushing to control the particle size of the crushed products (unqualified materials are screened out or returned to the crusher for crushing until the particle size requirements are met), which can be called inspection screening. Its purpose is to screen out the unqualified large pieces from the products of the crushing equipment, so that the products do not exceed the upper limit of the required particle size.

4. Selective screening

In some cases, screening needs to separate bulk materials by mass, such as separating sand and stone powder by grade in a sand and gravel production line. This kind of screening is called selective screening.

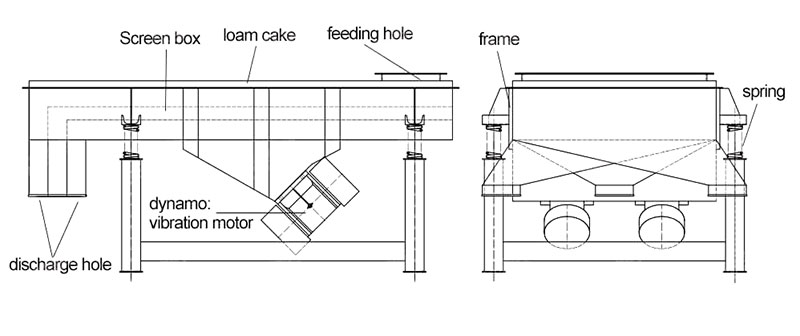

The sand screening machine is made of high-quality Q235 carbon steel, with a thickness of up to 8mm; a distributor is installed at the feed inlet to increase the width of the machine-made sand on the net, and buffer and protect the screen surface; the dual-channel design inside the screen box allows the machine-made sand to be screened and transported on both sides ;5mm woven mesh, detachable steel frame; driven by double motors, strong screening ability;

Screening process: the sand and gravel put into the screen are scattered on the screen and jump forward under the exciting force generated by the dual motors of the same frequency, and the powder and particles smaller than the mesh size in the material fall through the screen. The sundries larger than the mesh size are discharged from the screen surface through the slag outlet, thus completing the screening work.

Sieve sand

It is suitable for the classification of medium and fine range sand and natural wet sand, such as quartz sand, mullite sand, river sand, manganese sand, foundry sand, machine-made sand, etc.

Multi-layer grading

6 decks can be installed to separate different specifications of sand during the screening process, 7 different specifications can be separated, and the sand can be divided into coarse, medium and fine granularity levels.

96% screening efficiency

Using multiple layers (generally 3 to 6 layers), large inclination angle (generally 30° to 60°), and large sieve holes (the size of the sieve holes is 2 to 10 times the separation particle size), the screening efficiency is as high as 96%.

Large output

Driven by dual motors to ensure proper vibration, it is 3-6 times the output of ordinary screen machines, and the output can reach more than 80 tons/hour.

Feed evenly

A distributor can be added to the feeding section to ensure that the sieves are evenly distributed on the screen surface, and at the same time, it can buffer and protect the screen surface.

Flexible configuration

The upper cover of the equipment is designed with a dust removal device. It can be easily connected with on-site dust removal equipment. In large production lines, multiple screening equipment can be configured.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

| Materials | Proportion | Mesh | Capatity kg/h |

Model |

| Quartz sand | 1.6 | 70 mesh | 30000 | DZSF-1540-3s |

| Machine-made sand | 1.35 | 2mm | 60000 | DZSF-1540-1s |

| gravel | 2.65 | 6mm | 40000 | DZSF-1030-2s |

| drying sand | 2.1 | 0.05-2mm | 15600 | DZSF-525-2s |

| Emery | 4 | 60 mesh | 300 | DZSF-515-1S |

Screening quartz sand

It is used to screen and classify quartz sand and other materials. The specifications are: 0.5-1mm, 1-2mm, 2-4mm, 4-8mm, 8-16mm, 16-32mm, 10-20 mesh, 20-40 mesh, 40 mesh -80 mesh and 100-250 mesh can meet various application requirements and ensure that the particle size of quartz sand meets the requirements of use.

Screening corundum

Carborundum is used as abrasive, screening specifications: 0-1mm, 1-3mm, 3-5mm, 5-8mm, 8-10mm, 36 mesh, 46 mesh, 60 mesh, 80 mesh, 100 mesh, 200 mesh, 325 mesh and various A variety of fine powder can be adjusted and produced according to customer requirements.

Sieving machine-made sand

The sand making sand screening machine can have 1~8 layers of detachable screen layers according to the production needs of customers, and can screen out 7-9 kinds of machine-made sand with different particle sizes at most. At the same time, the maximum output can reach 40 tons per hour.

In the production line of sand and gravel, the sand screening machine has become the first choice for users. Its large screening capacity plays a decisive role in the quality and output of the produced stones and sand. In the sand and gravel production process, the use of the screening machine should also pay attention to some problems:

1. Screening from coarse to fine

If the screening is from coarse to fine, the screen surface of the sand screening machine overlaps according to the thickness, and at the same time, the screen surface with the large screen size should be placed on the top, so that it is not easy to wear. If the excitation force of the screening machine is increased, the fine particles can fully pass through all the screen surfaces, thereby reducing the chance of inclusion in the coarse-grained products.

2. Screening from fine to coarse

In the case of screening from fine to coarse, in order to facilitate the discharge, and to reduce the inclusion of fine particles aggregated by the discharge of various specifications. With this screening sequence, the structure size of the sand screening machine should be larger, and all the materials will pass through the fine screen surface first, which will accelerate the wear of the fine screen surface.

3. Appropriate screening methods should be used

During the screening process, wet screening or dry screening should be selected according to the mud content and water content of the materials in the sand screening machine. During the wet screening process, it is necessary to sprinkle water on the materials of the screening machine to reduce the viscosity of the mud and stone and prevent the screen holes from being blocked. If dry screening is used, it is generally used when the mud content or water content is small.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.