In the realm of food processing and manufacturing, the efficient handling of materials is paramount. One key equipment that plays a crucial role in this process is the food grade bucket elevator. These elevators are designed to transport bulk materials vertically, offering a reliable and hygienic solution for conveying food products within production facilities. When considering the purchase of a food-grade bucket elevator, several factors come into play, including the price. Let's delve into the key aspects that influence the food grade bucket elevatorprice:

| bucket volume | 1.8L | 3.6L | 6.5L |

| bucket material | pp | ss304 | ABS |

| body material | mild steel | stainless steel | --- |

| NO.S of discharge port | single | muti-discharge port | --- |

| output | 4-6m3/h | 6.5-8m3/h | 5.5-12m3/h |

| voltage(v) | 220v/240v/as you need | 380v/415v/440v/as you need | as you need |

| speed | adjustable | ||

| conveying capacity | 3-10m3/h | ||

| price | $801.90-$874.80 | $1,000.00-$3,000.00 | $3,000.00-$6,000.00 |

1. Capacity and Size

The capacity of a bucket elevator, measured in terms of material throughput per unit of time, significantly impacts its price. Larger capacity elevators with higher throughput capabilities generally come at a higher cost. Additionally, the physical size of the elevator, determined by factors such as the number and size of buckets, also influences the price.

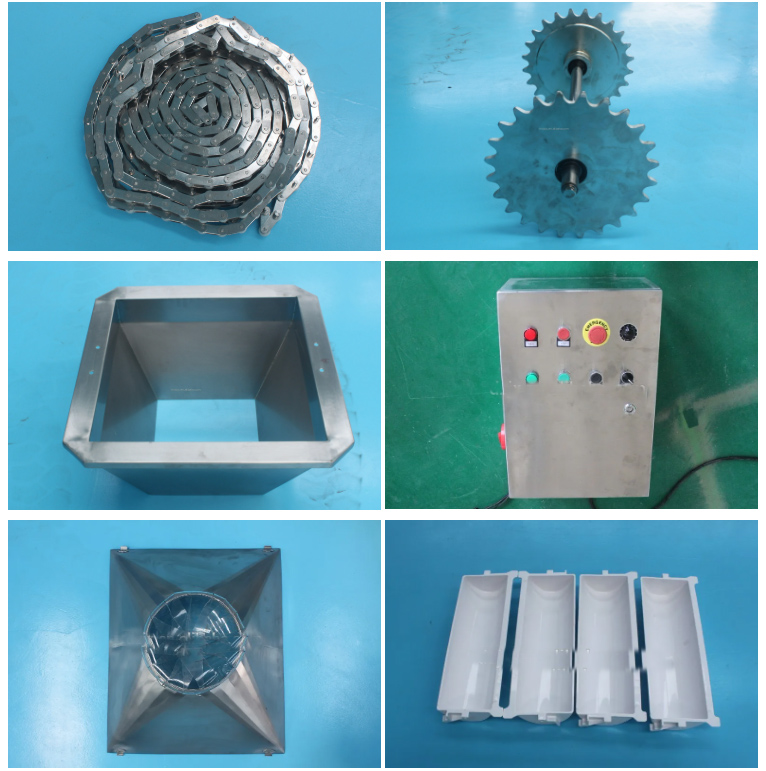

2. Material of Construction

Food-grade bucket elevators are typically constructed using materials that comply with strict sanitary standards to ensure the safe handling of food products. Stainless steel is a common choice due to its durability, corrosion resistance, and ease of cleaning. The quality and grade of the materials used in construction can affect the price of the elevator.

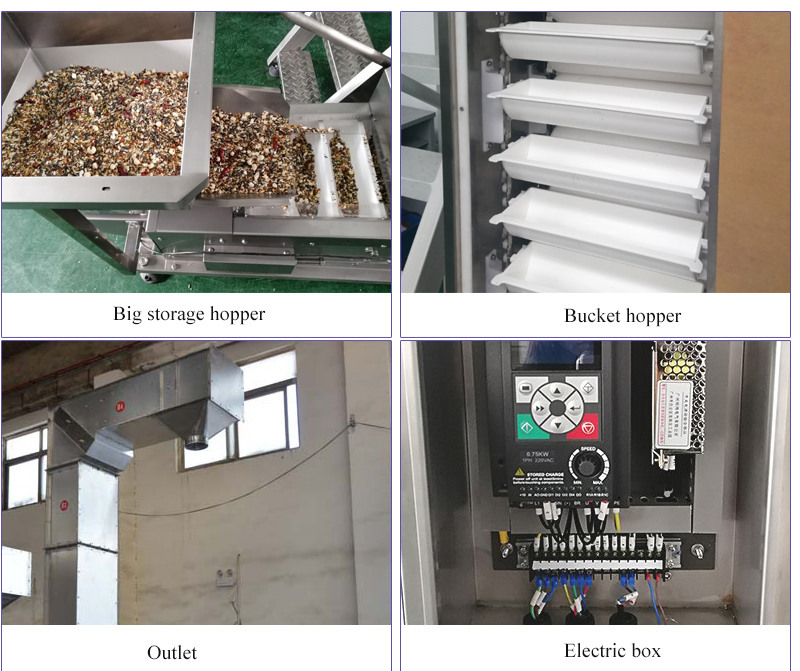

3. Design and Features

The design of the bucket elevator, including the type of buckets, belt or chain configuration, and discharge options, can impact its price. Elevators with specialized features such as self-cleaning mechanisms, explosion-proof design, and adjustable speed control may come at a higher cost but offer added functionality and safety benefits.

4.. Brand Reputation and Service Support

The reputation of the manufacturer and the level of after-sales service and support they provide can influence the price of a food-grade bucket elevator. Established brands known for their quality, reliability, and customer service may offer products at a premium compared to lesser-known manufacturers.

5. Customization and Installation

Customization options, such as specific height requirements, discharge configurations, and integration with existing production lines, can impact the price of a food-grade bucket elevator. Additionally, installation costs, including labor, equipment setup, and training, should be factored into the overall price.

Conclusion

When evaluating the price of a food-grade bucket elevator, it is essential to consider a combination of factors such as capacity, construction materials, design features, certifications, brand reputation, and customization options. By carefully assessing these aspects and comparing offerings from different manufacturers, food processors can make informed decisions to select a high-quality and cost-effective solution that meets their specific requirements for safe and efficient material handling in food production environments.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.