Rotary vibrating screen is currently a common screening machine in the industry. It has stable operation and high screening efficiency. It is widely used in the screening and filtration of particles, powder, mucus and other materials. It is widely used in the industry and is suitable for industry, food industry, For the metallurgical industry, etc., there are many types of rotary vibrating screen, which are introduced one by one below:

Rotary vibrating screen mainly includes DH-600, DH-800, DH-1000, DH-1200, DH-1500, DH-1800, DH-2000 and other models. Different types of rotary vibrating screen have different sieve sizes and sieve weights.

According to different materials, it can be classified into all-carbon steel rotary vibrating screen, standard-type rotary vibrating screen, all-stainless steel rotary vibrating screen, and plastic rotary vibrating screen:

1. Standard rotary vibrating screen

A combination of carbon steel and stainless steel. The contact surface between the body and the material is made of 304 stainless steel, and the base is made of ordinary carbon steel.

2. All stainless steel rotary vibrating screen

The whole machine is made of 304 stainless steel, the screen machine is strictly polished, welded and polished to meet the diverse needs of users.

3. All carbon steel rotary vibrating screen

Carbon steel material, low cost, suitable for general material screening and filtering, suitable for products with low budget cost, small demand, and low product requirements.

4. Plastic rotary vibrating screen (polypropylene vibrating screen)

This type of model is less and has a limited scope of application. It is mainly used under strong acid and strong alkali conditions.

Of course, in order to meet the needs of multiple users, we will also customize the rotary vibrating screen according to the needs of customers: several special designs are used:

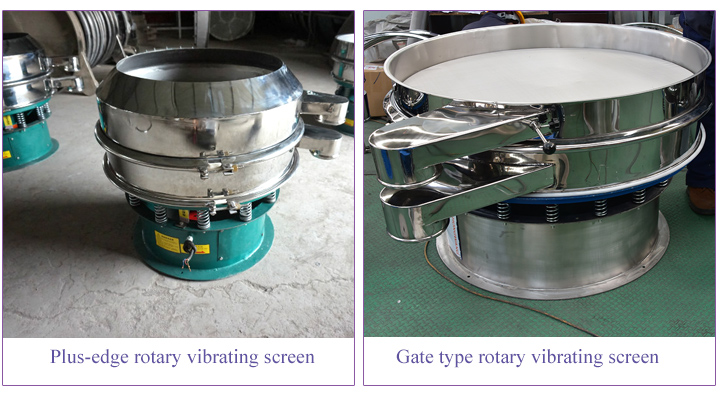

1. Plus-edge rotary vibrating screen

This kind of vibrating screen expands its inlet on the basis of ordinary vibrating screen, supplemented by special angle design to prevent liquid splashing filtration technology, so as to save cost, reduce waste and increase workload.

2. Gate type rotary vibrating screen

The main purpose of the design is to remove impurities. The main working principle is to control the in and out of materials by controlling the gate, so as to achieve the purpose of good screening and reduce the manual workload.

The above are several types of rotary vibrating screen, which can meet your various screening needs.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.