Dry Material Silica Powder Vibrating Sieve is designed for sieving ultra-fine, lightweight and easily agglomerated silica powder. Depending on production needs, we will use different types of vibrating screens to achieve the best results. Linear vibrating screen is suitable for silica powder separation between 10 mesh and 200 mesh, providing high-yield multi-layer grading. When finer grading is required, ultrasonic vibrating screen can effectively handle silica powder as fine as 300 mesh to 500 mesh, breaking static adhesion and ensuring high-precision separation. For applications that require cleanliness and chemical corrosion resistance, stainless steel vibrating screen performs well in the range of 20 mesh to 400 mesh, ensuring material purity and durability.

Silica Powder Linear Vibrating Sieve adopts horizontal or slightly inclined vibrating motion, which is very suitable for processing silica powder with mesh size ranging from 10 mesh to 200 mesh. It is generally used for coarse grading, dust removal and preliminary separation. The multi-layer design can separate into 2-5 particle size fractions at the same time, significantly improving production efficiency. In addition, linear sieves are highly efficient in large batch processing due to their large screening area and sturdy structure.

Ultrasonic Vibrating Screen for Silicon Powder is designed for ultra-fine and lightweight materials such as silicon powder. By adding an ultrasonic generator to the standard vibration system, the powder is prevented from agglomerating, sticking or clogging the screen. It is very effective for screening silicon powder between 300 mesh and 500 mesh. Ultrasonic vibration technology increases the screening capacity by 1.5 to 5 times compared to standard sieves, ensuring excellent separation accuracy even for difficult-to-screen powders.

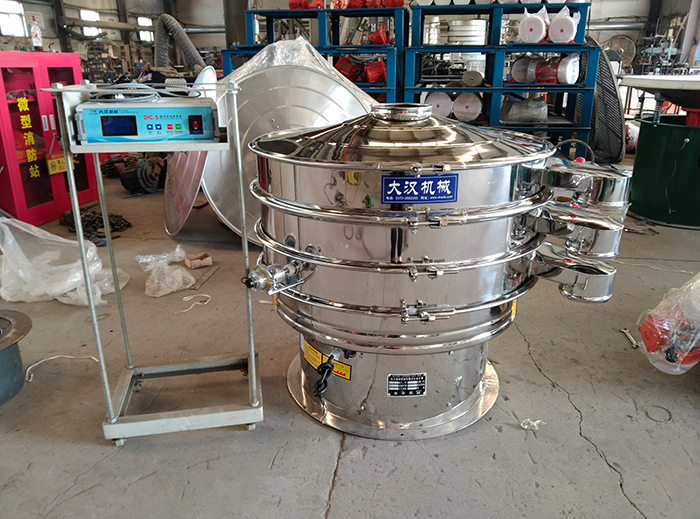

Stainless Steel Vibrating Screen for Silicon Powder For industries with strict hygiene or corrosion protection requirements, stainless steel vibrating screens are the ideal solution. The screen is made of SS304 or SS316L, ensuring high screening efficiency and excellent chemical resistance. Its wide range of particle sizes, from 20 mesh to 400 mesh, is suitable for both wet and dry screening processes.

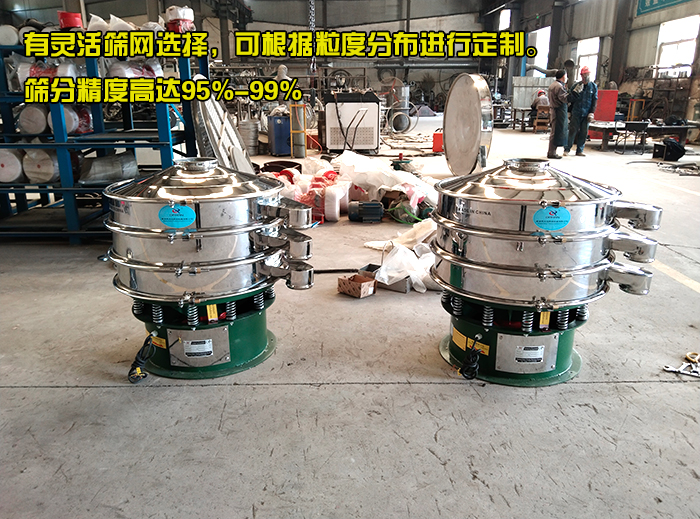

The Dry Material Vibrating Screen for Silicon Powder has flexible screen options that can be customized according to particle size distribution. Its screening accuracy is as high as 95%-99%, which can efficiently separate fine powder. The fully enclosed design prevents silicon powder leakage and environmental pollution. The dry silicon powder vibrating screen is equipped with an energy-saving vibration motor, which has lower operating power consumption. The modular structure makes it easy to replace the screen and cleaning equipment, thereby minimizing downtime and improving overall production efficiency.

Dry silicon powder vibrating screen is widely used in electronic materials, building materials, ceramics, coatings and other industries. Many customers choose to use ultrasonic vibrating screens when screening dry silicon powder, which effectively solves the problem of easy agglomeration and clogging of fine powder. The screening accuracy is stable at 300-500 mesh, and the yield rate is significantly improved. For coarse-grained silicon powder, customers often use linear vibrating screens for efficient grading of 10-200 mesh, ensuring production capacity while reducing dust leakage. In the chemical and food fields, stainless steel vibrating screens are widely used for 20-400 mesh screening to ensure the purity of materials due to their corrosion resistance and easy cleaning characteristics.

Silica powder is fine, lightweight and easily agglomerated, which presents unique challenges to the screening process. In industries such as electronics, ceramics, construction and metallurgy, efficient separation is critical because particle size consistency and purity directly affect product quality. Dry Silica Vibrating Screens address these challenges by combining advanced vibration technology with material-specific screen configurations.

The core benefits of silica vibrating screens are their ability to perform high-precision classification, dust-free operation and efficient material flow control. Whether for coarse or ultra-fine classification, choosing the right vibrating screen model is critical to achieving the desired results.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.