Double Shaft Paddle Mixers for powder mixing is a kind of equipment used for drying and mixing powder materials such as dry mortar, chemicals, pesticides, detergents, rubber additives, etc. It is also called double-shaft paddle zero-gravity mixer or double-shaft paddle zero-gravity mixer.

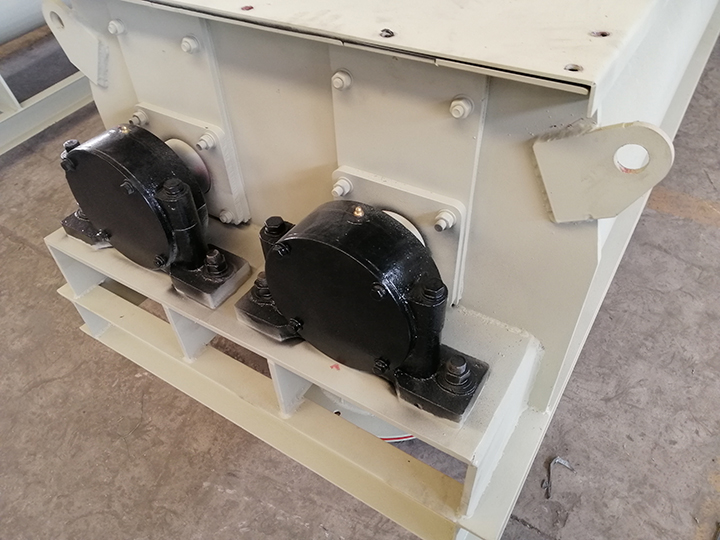

Double shaft paddle mixers consist of two horizontal shafts with interconnected paddles that rotate in opposite directions. The paddles are arranged in a specific configuration to create a fluidized mixing action. As the shafts rotate, the paddles lift the materials upwards and then drop them back down, ensuring thorough mixing and blending of the powders. This gentle yet effective mixing action results in a homogeneous mixture with minimal product degradation.

It is equipped with two parallel shafts rotating in opposite directions and paddles with different preset angles. The linear speed of the rotating stirring material exceeds the zero speed and reaches the parabola point, that is, the point of zero gravity.

The overlapping double-shaft paddles move in opposite directions, which produces high mixing efficiency and can evenly mix materials of different particle sizes and densities.

The equipment runs stably and can be customized according to user needs. It has the characteristics of efficient and fast mixing.

Dual-Shaft Configuration: The presence of two shafts with paddles ensures a more thorough mixing process by creating multiple material flow patterns.

Paddle Design: The paddles are strategically positioned on the shafts to promote material movement and prevent clumping or segregation.

Variable Speed Control: Many double shaft paddle mixers offer adjustable speed settings to cater to different mixing requirements.

Jacketed Mixing Chamber: Some mixers come with a jacketed mixing chamber for temperature-sensitive materials or processes.

Discharge Options: These mixers may feature various discharge options, such as slide gate s or butterfly valves, for easy material transfer.

Double shaft paddle mixers are commonly used in industries for efficient powder mixing. These mixers have two shafts with paddles that rotate in opposite directions, creating a fluidized mixing action. This design ensures thorough blending of powders, achieving uniformity and consistency in the final product. The gentle mixing process of double shaft paddle mixers helps prevent product degradation and ensures a high-quality mix.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.