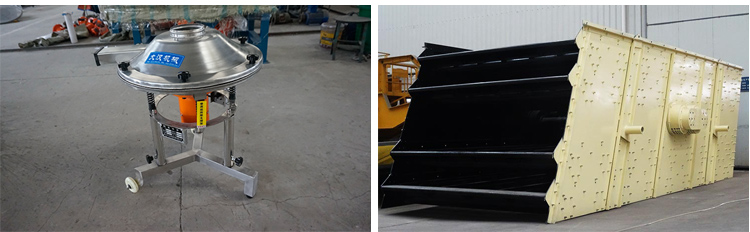

The high-frequency vibrating screen may be unfamiliar to everyone, and some users may not be able to distinguish the high-frequency vibrating screen from the vibrating screen. So today, Xiaobian will introduce the difference between the high-frequency vibrating screen and the ordinary vibrating screen.

1.The difference ofscreening materials

The high-frequency vibrating screen adopts high frequency, low amplitude, and the frequency can reach 3000 r/min. Moreover, the slurry discharge port is installed on the vibrating body, which facilitates the efficient and smooth discharge of the filtered slurry.

The type of liquid suitable for screening by the ordinary vibrating screen is the material with lower viscosity and more impurities, because more material on the screen is easier to discharge from the discharge port of the material on the screen. It is mainly composed of screen box, vibration exciter, suspension (or support) device and motor. The motor drives the main shaft of the exciter to rotate through the V-belt, and the screen box vibrates due to the centrifugal inertial force of the unbalanced weight on the exciter. By changing the eccentric weight of the exciter, different amplitudes can be obtained.

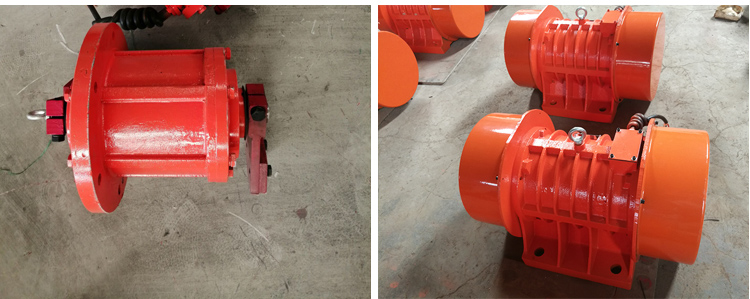

2. The difference ofmotor configuration

The vibration frequency of the high-frequency vibrating screen is increased from the original 1440r/min to 3000r/min.

The motor used for ordinary vibration screening is a 4-stage vertical vibration motor, and the speed of this type of motor is 1500rpm.

3. The difference of screening effect

The high-frequency vibrating screen is mainly a special type of screening equipment produced to deal with the filtration of thick slurry. Therefore, in order to ensure the efficient filtration and screening of the slurry, it usually adopts a single-layer open design. Therefore, in terms of screening effect, the high-frequency screen is only It can handle filtration and impurity removal, and cannot be used for classification with more than 2 particle sizes.

Ordinary vibrating screen is a general-purpose multi-functional screening equipment. The number of screen layers can be customized from 1 to 5 layers according to the different screening purposes of customers. The customer needs to carry out 2-6 levels of particle size classification for powder particles.

The above is the difference between high-frequency vibrating screen and ordinary vibrating screen, I hope it can help you to better distinguish products and choose products.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.