Ceramic powder for inclined screw conveyor is a kind of equipment specially used to transport ceramic powder. Compared with ordinary screw conveyors, the characteristic of the ceramic powder for inclined screw conveyor is that its conveying angle can be adjusted, and the inclination angle can be adjusted according to specific process requirements. This can better control the flow of ceramic powder during transportation and avoid problems such as excessive collapse or accumulation. In addition, the equipment is usually made of wear-resistant and high-temperature-resistant ceramic materials, which can adapt to the special properties of ceramic powder and also has good wear resistance and service life.

1. Raw material transportation in the ceramic production process: In the ceramic production process, ceramic powder or granular raw materials need to be transported from one location to another. The ceramic powder for inclined screw conveyor can effectively transport ceramic powder or granules to ensure production. Process continuity and efficiency.

2. Particle transportation during the production process of ceramic tiles: In the production process of ceramic tiles, ceramic powder or particles need to be transported from the raw material warehouse to the feeder or mixer for mixing or preparation. Ceramic powder tilted spiral The conveyor can reliably transport ceramic powder or granules and realize automated production.

3. Waste processing in ceramic production: In ceramic production, some waste will be produced. The ceramic powder for inclined screw conveyor can transport the ceramic waste to the waste processing equipment for recycling or processing.

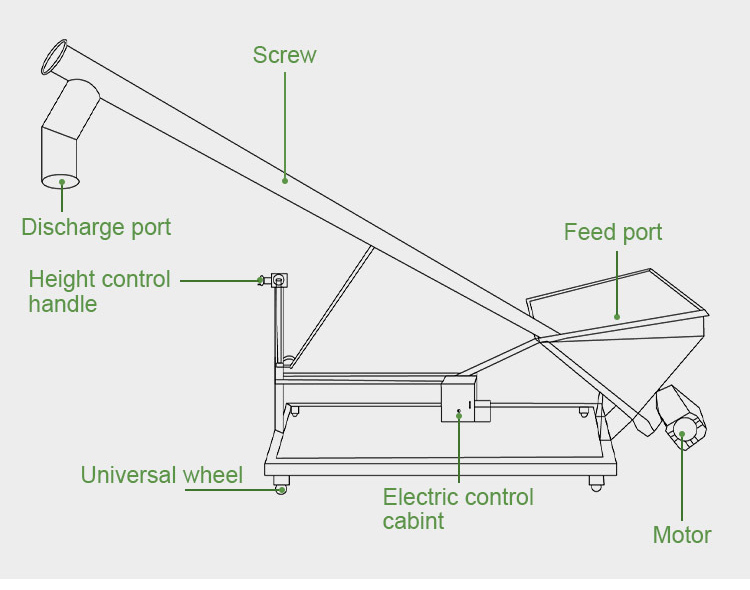

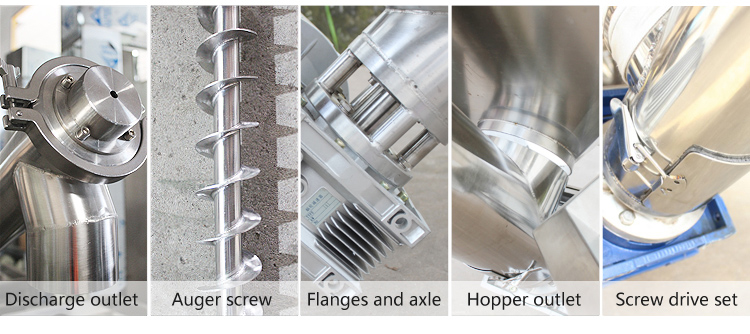

The device consists of an inclined spiral pipe and a driving device. The spiral pipe is mainly responsible for loading and transporting ceramic powder, and the driving device is used to provide power to push the ceramic powder to move in the spiral pipe.

The working principle of the ceramic powder for inclined screw conveyor is to drive the spiral pipe to rotate through the driving device, and transport the ceramic powder upward from the feed port along the spiral pipe to the set position. Due to the inclination angle of the spiral pipe, the ceramic powder will be affected by gravity during movement, resulting in a downward force, so it is called an inclined conveyor. At the same time, the spiral shape inside the spiral pipe causes the ceramic powder to be subject to friction during movement, preventing the powder from sliding or accumulating during transportation.

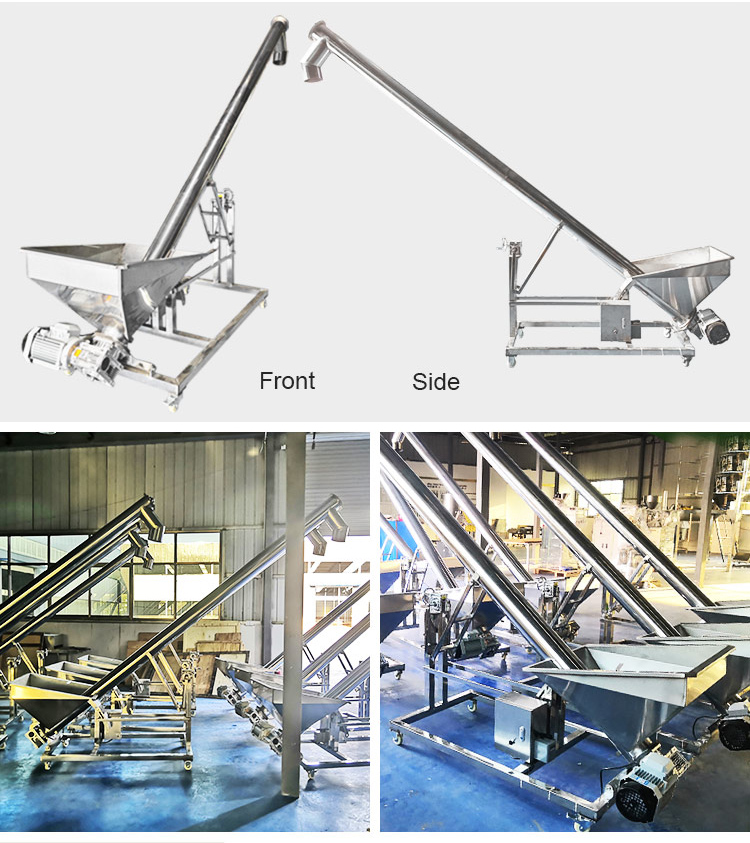

1. Simple and compact structure: The device mainly consists of a spiral pipe and a driving device. It has a simple and compact structure, is easy to install, and occupies a small area.

2. Long conveying distance: Due to the inclined design, the ceramic powder inclined screw conveyor can achieve a long conveying distance and is suitable for long-distance conveying needs.

3. Large conveying capacity: This device has a large conveying capacity and can be adjusted and customized according to actual needs to meet different production requirements.

4. Strong adaptability: Ceramic powder inclined screw conveyor is suitable for conveying a variety of granular and powdery materials, such as ceramic powder, grain, chemical raw materials, etc., and has good versatility.

5. Stable and reliable operation: The device adopts advanced driving device and has the characteristics of stable and reliable operation. At the same time, the inner wall of the spiral pipe is made of wear-resistant materials, which improves its service life.

1. Shaft series

The conveying angle of the shafted tube screw conveyor is about 45°, while the conveying angle of the shafted U-shaped screw conveyor is about 20°-30°.

2. Shaftless series

The conveying angle of the shaftless tubular screw conveyor is about 30°, while the conveying angle of the shaftless U-shaped screw conveyor is about 20°-30°.

The larger the angle of the inclined screw conveyor, the worse the conveying effect (there is no effect within 15°, and the conveying efficiency will decrease by 15% for every 5° increase).

At this time, the following items need to be considered:

More horsepower is required for inclined screw conveyors: This is due to both lifting the product and "reconveying" product that falls back.

Hangers should be eliminated: They create a "dead flow" area that is emphasized with inclined conveyors. This often results in the use of longer screws which require their own design considerations.

For materials with poor fluidity, the inclination angle can reach 50°, but to convey materials in this way, a certain pressure needs to be applied to the feed inlet, and the added materials are squeezed into the conveying main body, and the bearing at the bottom of the equipment needs to bear huge pressure , The bearing is easily damaged.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.