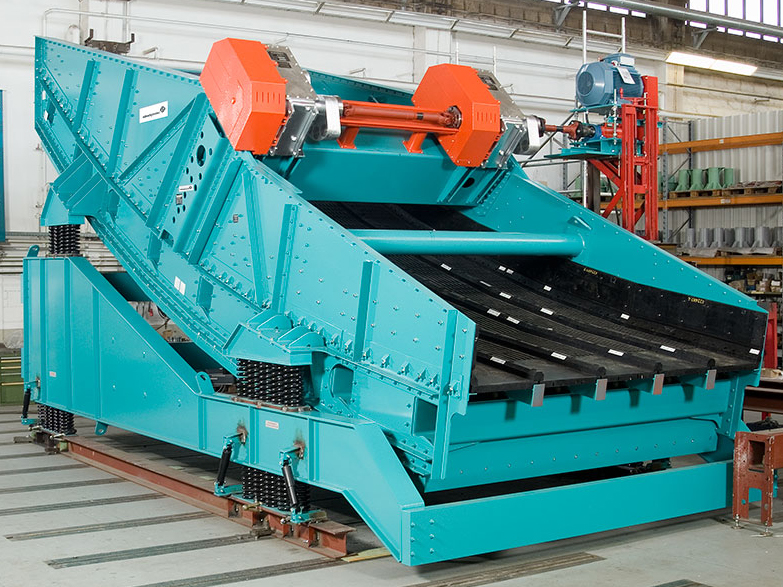

Banana-type vibrating screen is also known as linear equal thickness vibrating screen. The screen surface adopts multiple sections of screen plates arranged at different inclination angles. The longitudinal section is in the form of a broken line. The entire screen surface is banana-shaped, which ensures that the material layer thickness from the feed end to the discharge end is basically the same, greatly improving the screening efficiency and processing capacity of the screen machine. It is particularly suitable for the particle size classification of large and medium-sized materials with high fine particle content. It can also be used for dehydration, de-mediuming and de-sludge operations (fine particles refer to particles with a particle size less than half of the size of the screen hole).

It is mainly composed of a screen box, an exciter, a suspension (or support) device and an electric motor. The motor drives the exciter main shaft to rotate through a V-belt. Due to the centrifugal inertia force of the unbalanced weight on the exciter, the screen box vibrates. By changing the eccentric weight of the exciter, different amplitudes can be obtained.

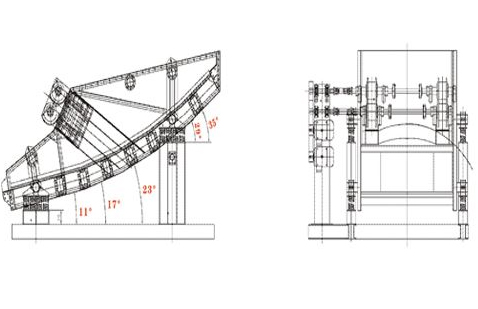

Applying the principle of equal thickness screening, different vibration parameters, number of segments and screen surface inclination angle are adopted for different material characteristics. The screen surface inclination angle is smooth, and the number of screen surface segments is 4 to 7, which can ensure the best screening process effect. At the same time, the smooth inclination transition and the large number of segments are conducive to improving the life of the screen surface.

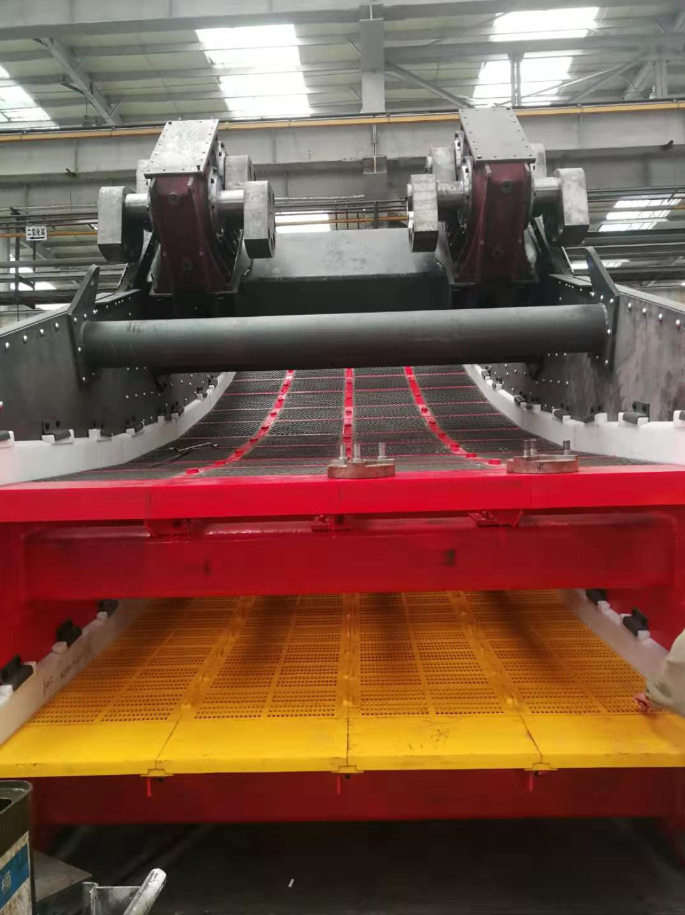

Vibrator: Adopting the world's advanced JR box vibrator (see the introduction of JR vibrator for details), splash lubrication, built-in lubrication oil channel in the box to ensure full lubrication of the bearings, high-precision helical gears, bearings for vibration equipment special bearings, oil drain plugs with magnetism, external organic plastic transparent oil mark, can easily observe the oil level, special measures are adopted to ensure the comfortable operation of bearings and gears, the vibrator noise is less than 75 decibels, and the bearing temperature is less than 50 degrees.

The exciter beam adopts a three-I-beam structure, which overcomes the problem of poor force in the middle of the square beam. It is equipped with a reinforcing rib plate, has high rigidity, light weight, and stress relief after welding.

The lower crossbeam supporting the screen surface adopts a special I-beam. The connection between the crossbeam and the screen surface system is a high-strength bolt connection, which avoids the problem of local stress concentration of the crossbeam caused by welding and the low life of the crossbeam. At the same time, users can easily maintain the screen surface system.

The side panel shape cutting and drilling are completed by a high-precision CNC lathe to ensure the accuracy of the shape and drilling. There is no weld on the side panel to avoid stress concentration on the side panel, thereby preventing the side panel from cracking.

There are two ways to fix the screen surface, one is the polyurethane pressed wood middle rail seat type at both ends, and the other is the polyurethane pressed wood middle pressure plate type at both ends. The polyurethane screen surface can be installed, or the stainless steel screen surface can be installed. Users can choose according to their needs, which is very flexible.

The banana vibrating screen has a slope surface at the feed end, starting at 34°, and then the angle drops to about 10° at the discharge end. The screen surface adopts a broken line form with different inclinations, and the thickness of the material layer from the feed end to the discharge end is constant. The ratio of material quantity to flow rate on each section of the screen is stable, the material layer is high, and the screening efficiency is significantly improved, which is 1-2 times higher than the processing capacity of the screening machine with the same effective area. For high fine particle content, especially when the material content in the material is less than 1/2 of the graded particle size, the banana-type vibrating screen has a higher screening efficiency.

The banana screen is mainly composed of a screen box, a screen mesh, an exciter, a vibration damping spring and a lower frame. The banana screen uses an electric motor and an exciter as vibration sources. The exciter is mainly composed of an eccentric shaft, a pulley, a bearing and a bearing seat. The exciter is installed on the side plate of the screen box and is connected to it by a motor through a V-belt or a soft connection. The motor drives the eccentric shaft to rotate, generating a centrifugal inertia force, forcing the screen box to vibrate.

| model |

Screen area (m2) |

Feed size (mm) |

Processing capacity (t/h) |

Screen surface inclination |

Screen size (mm) |

Double Amplitude (mm) |

Voltage (V) |

power (kW) |

| ZXD1560 | 9 | ≤300 | 80-400 |

5°-25° 5 Segment screen surface |

5-50 | 8-12 | 380 | 2x11 |

| ZXD2060 | 12 | 110-500 | 2x15 | |||||

| ZXD2560 | 15 | 130-650 | 2x18.5 | |||||

| ZXD3060 | 18 | 160-750 | 2x22 | |||||

| ZXD3073 | 21.9 | 190-800 | 2x30 | |||||

| ZXD3642 | 15.12 | 130-650 | 2x15 | |||||

| ZXD3660 | 21.6 | 200-800 | 2x22 | |||||

| ZXD2590 | 22.5 | 200-800 | 2x22 | |||||

| ZXD3090 | 27 | 240-1100 | 2x30 | |||||

| ZXD3690 | 32.4 | 300-1350 | 2x37 |

The application scope of the vibrating screen is very wide, almost involving all aspects of life. Various types of vibrating screens are needed in processing and manufacturing.

Vibrating screens are mainly used in mining, coal, smelting, building materials, refractory materials, light industry, chemical industry, medicine, food and other industries.

Vibrating screens are widely used in ore dressing plants. According to their transmission mechanisms, they can be divided into the following types: eccentric vibrating screens, inertial vibrating screens, self-centering vibrating screens, and resonance screens.

The banana-shaped vibrating screen is designed with a proprietary technology of injecting banana-shaped multi-segment screens into linear vibrating screens. There is a large slope screen surface at the feed end, which then descends step by step at a certain number of angles until it reaches the particle outlet. The slope screen surface at the feed end allows more materials to pass through the screen surface with a higher screening speed and thinner material stratification. Because large pieces of material pass through the steep slope faster, this early stratification allows fine particles to approach the screen surface faster and pass through the gaps relatively unhindered. Therefore, the banana-shaped vibrating screen has extremely high screening efficiency and a processing capacity that is 1.5-2 times higher than that of traditional grading screens. It is a popular screening machinery product.

| use | model | Feed sizemm | Processing capacityt/h | Motor | |

| Power KW | |||||

| Grading | ZXD-12*61 | ≤300 | 130-420 | 2*11 | |

| ZXD-12*61 | ≤300 | 130-420 | 2*15 | ||

| ZXD-18*61 | ≤300 | 200-640 | 2*15 | ||

| ZXD-18*61 | ≤300 | 200-640 | 2*30 | ||

| ZXD-24*61 | ≤300 | 260-1400 | 2*22 | ||

| ZXD-24*61 | ≤300 | 260-1400 | 2*30 | ||

| ZXD-30*61 | ≤300 | 330-1700 | 2*30 | ||

| ZXD-30*73 | ≤300 | 360-1800 | 2*30 | ||

| ZXD-36*61 | ≤300 | 400-2000 | 2*30 | ||

| ZXD-36*73 | ≤300 | 440-2200 | 2*30 | ||

| ZXD-24*61 | ≤300 | 460-2400 | 2*45 | ||

| ZXD-42*86 | ≤300 | 650-2800 | 2*55 | ||

|

Dehydration Desuke |

ZXD-12*61 | ≤80 | 80-150 | 2*11 | |

| ZXD-12*61 | ≤80 | 80-150 | 2*15 | ||

| ZXD-18*61 | ≤80 | 120-210 | 2*15 | ||

| ZXD-18*61 | ≤80 | 120-210 | 2*30 | ||

| ZXD-24*61 | ≤80 | 160-240 | 2*22 | ||

| ZXD-24*61 | ≤80 | 160-240 | 2*30 | ||

| ZXD-30*61 | ≤80 | 200-360 | 2*30 | ||

| ZXD-30*73 | ≤80 | 240-420 | 2*30 | ||

| ZXD-36*61 | ≤80 | 240-430 | Y250M-4 | 55 | |

| ZXD-36*73 | ≤80 | 290-500 | Y280S-4 | 75 | |

| ZXD-42*86 | ≤80 | 360-700 | Y315S-4 | 110 | |

Address:China,Yanjin county forest park gate to the west 1000 meters north road.