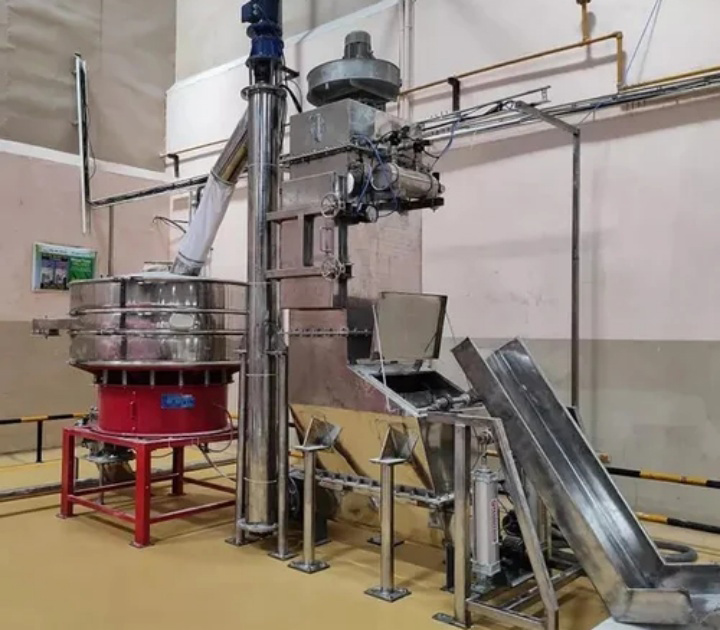

The general process of the papermaking process is: material preparation--cooking--washing--screening--bleaching--beating--finally sent to the paper machine through wire dehydration, pressing dehydration, drying cylinder, calendering and coiling. In the whole process, the following five steps are required for the circular vibrating sieve to play the role of sieving and impurity removal.

1. Pre-screening of raw dry lime

In the pulp and paper industry, a large amount of lime is usually used for clarification and bleaching, and the dry lime must be screened by vibrating sieve before entering the slurry lime tank to ensure that the particle size of the material entering the slurry lime tank is uniform. It can prevent other impurities from affecting the effect of the paper, and secondly, it can also ensure that the lime can fully contact the pulp to ensure a good clarification and bleaching effect.

2. Screening and impurity removal of papermaking fillers

Papermaking fillers refer to some substantially water-insoluble solid particles added to the pulp. The purpose of addition is to improve the opacity, brightness, smoothness, printability, softness, uniformity and dimensional stability of the paper. It can also make the paper feel good, reduce its hygroscopicity and reduce the amount of fiber. The more commonly used papermaking filler materials are talcum powder, porcelain powder, slurry calcium carbonate and slurry titanium dioxide.

These powdery materials will inevitably produce impurities in the process of pulverization, which requires the use of vibrating sieve separators to finely sieve these materials, so as to ensure the quality and flatness of the paper and improve the accuracy of papermaking fillers.

3. Crude fiber filtration of papermaking white water

Papermaking white water is the waste water in the papermaking workshop, which comes from the papermaking process of the papermaking workshop. White water mainly contains fine fibers, fillers, coatings and dissolved wood components, as well as added sizing agents, wet strength agents, preservatives, etc. Medium: calcium carbonate, starch and traces of other compounds, white water discharge is large, and these White water also contains a lot of paper fibers, and the vibrating sieve separator can effectively filter the recyclable substances in it to form secondary utilization, which not only reduces environmental pollution, but also saves materials.

4. High-precision screening of paper coatings

Papermaking coatings are mainly used to improve the printability and appearance of paper, and to perform surface treatment on the base paper to achieve the desired effect; pigment coatings are commonly used. Pigment coatings are mainly composed of pigments and adhesives. The screening of pigments is also a high-precision sieve. Points, Dahan circular vibrating sieve can complete this process very well.

5. Screening and recycling of papermaking wastewater

The circular vibrating sieve plays the role of a filter grid in the pretreatment of industrial wastewater produced in the paper industry, effectively removing large particle pollutants in the wastewater. The wastewater passes through an artificial grid to remove coarse particles such as plastic bags, branches, leaves, etc. In order to ensure the amount of pulp recovered and the quality of the effluent, reduce the load of the subsequent process, the recycled fiber is used for secondary production, the sludge screened by the vibrating sieve separator is stored for a long time and used as agricultural fertilizer, and the pulp in the wastewater is recycled. Reducing the cost of wastewater treatment to meet the standard is really killing two birds with one stone.

The above is the application of Dahan vibrating sieve in the papermaking process. It can be said that the color, feel and toughness of the finished paper are closely related to the role played by the vibrating sieve. Vibrating sieve is incorporated into the production line, If you are interested in our vibrating sieve and want to know about other applications of vibrating sieve, please click on the online chat to contact us directly, and we will be happy to introduce it to you.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.