Dehydrated vegetables are often produced by removing the moisture from fresh vegetables, which can result in a product that is lighter and more fragile than the original vegetable. This can make the product moresusceptible to breaking or crumbling, which can result in the presence of small particles or foreign objects.Sieving machines are commonly used in the processing of dehydrated vegetables to separate the dried vegetables from any foreign objects, as well as to remove any oversized or undersized particles.

The application of sieving machines in the processing of dehydrated vegetables is critical to producing a high-quality final product. Here are some specific applications of sieving machines in the processing of dehydrated vegetables:

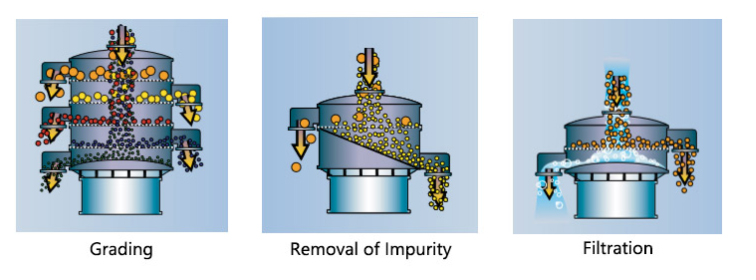

Removal of foreign objects: Dehydrated vegetables can be contaminated with foreign objects such as stones, twigs, or dirt during the harvesting and drying process. Sieving machines can be used to remove these foreign objects from the dehydrated vegetables, ensuring that the final product is safe for consumption.

Particle size classification: Sieving machines are used to classify the dehydrated vegetables based on their particle size. This helps to ensure that the final product has a consistent particle size distribution, which can improve the product's appearance, texture, and rehydration properties. Sieving machines can be used to separate the particles into different size fractions, which can then be used for different applications such as soup mixes, snack foods, or baby foods.

Removal of fines: During the dehydration process, some vegetables can break down into small particles or fines. These fines can be removed using sieving machines, which can improve the appearance and texture of the final product.

Quality control: Sieving machines are an important part of quality control in the processing of dehydrated vegetables. By removing foreign objects, classifying the particles based on size, and removing fines, sieving machines help to ensure that the final product is of a consistent quality and meets the required specifications.

Here is an example of a customer case involving the use of a sieving machine in the processing of dehydrated vegetables:

A food processing company in the United States was producing a range of dehydrated vegetables, including carrots, onions, and peppers. The company was experiencing issues with the consistency of the particle size distribution in their dehydrated vegetables, which was affecting the qual city of their final product.

Solution: To address this issue, the company invested in a vibrating sieving machine to separate the particles based on their size. The machine was able to remove any oversized or undersized particles, as well as any foreign objects or impurities, resulting in a more consistent and higher quality final product.

Results: The vibrating sieving machine was able to handle the high throughput rate required by the food processing company and was also easy to operate and maintain. The company reported that the use of the sieve machine had improved the consistency and quality of their dehydrated vegetables, resulting in increased customer satisfaction and sales.

The choice of sieving machine for sieving dehydrated vegetables will depend on several factors, such as the desired particle size distribution, throughput rate, and budget. Here are some common types of sieving machines that can be used for sieving dehydrated vegetables:

Vibrating sieving machine: Vibratingsieving machines use a vibrating motor to create a circular motion that separates the particles based on their size. They are often used for applications where a high throughput rate is required.

Rotary sieving machine: Rotary sieving machines use a rotating drum with perforated screens to separate the particles based on their size. They are often used for applications where a more gentle sieving action is required, such as for fragile dehydrated vegetables.

Ultrasonic sieving machine: Ultrasonic sieving machines use high-frequency vibrations to separate the particles based on their size. They are often used for applications where a high degree of accuracy is required, such as for powders or fine particles.

When selecting a sieving machine for sieving dehydrated vegetables, it's important to consider factors such as the desired particle size distribution, throughput rate, and the characteristics of the dehydrated vegetables, such as their fragility and moisture content. It's also important to choose a machine that is easy to clean and maintain, and that is compatible with the materials of construction used in the processing operation.

What are the factors to consider when choosing a sieving machine for dehydrated vegetables?

When choosing a sieving machine for dehydrated vegetables, there are several factors to consider to ensure that the machine is effective and efficient. These factors include:

Type of sieve machine: There are several types of sieving machines available, such as vibrating sieve machines, rotary sieve machines, and ultrasonic sieve machines. The choice of machine will depend on the specific application, throughput rate, and desired particle size distribution.

Particle size distribution: The desired particle size distribution of the dehydrated vegetables will determine the mesh size of the sieve that needs to be used. The mesh size of the sieve will also affect the throughput rate of the machine.

Capacity: The capacity of the machine needs to be considered to ensure that it can handle the required throughput rate of the dehydrated vegetables being processed. A machine with a higher capacity will have a higher throughput rate, but will also be more expensive.

Material of construction: The material of construction of the machine needs to be considered to ensure that it is compatible with the dehydrated vegetables being processed. For example, if the dehydrated vegetables are acidic, a machine made of stainless steel would be a better option.

Ease of cleaning and maintenance: The machine should be easy to clean and maintain to ensure that it operates efficiently and effectively. The machine should also be designed to prevent contamination and ensure food safety.

Cost: The cost of the machine needs to be considered to ensure that it fits within the budget of the processing operation. The cost of the machine will depend on the type of machine, capacity, and materials of construction.

Overall, the use of sieving machines in the processing of dehydrated vegetables is critical to producing a high-quality final product that is safe for consumption, has a consistent particle size distribution, and meets the required specifications.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.