Activated carbon for bucket elevator is a kind of mechanical equipment commonly used for carbon powder handling. Activated carbon is a material with good adsorption properties, which is widely used in environmental protection, water treatment, desulfurization and other industrial fields. Activated carbon for bucket elevator lifts activated carbon from a low place to a high place through the working principle of a bucket elevator to complete the task of conveying carbon powder.

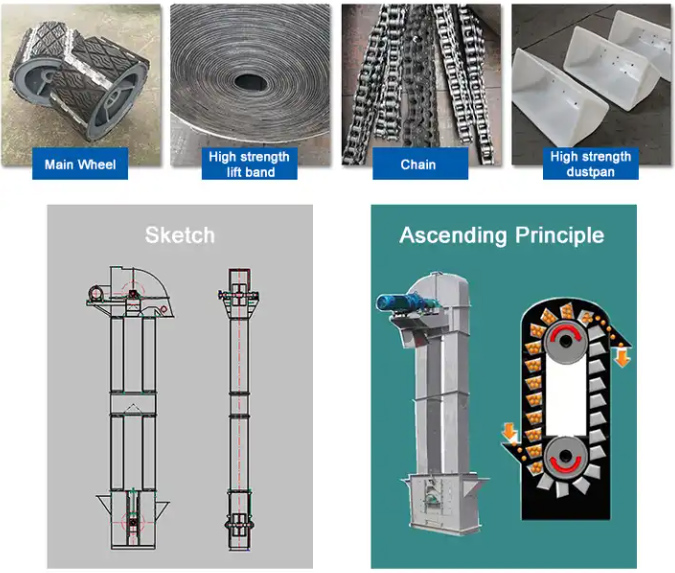

Activated carbon for bucket elevator is mainly composed of lifting frame, upper part, lower part, bucket group, transmission device and electrical control system. The hoist frame is the main part of the whole hoist, carrying bucket groups and transmission devices. The upper part is the feed port, and the lower part is the discharge port. By adjusting the height of the feed and discharge ports, the conveying amount of carbon powder can be controlled. The bucket group is composed of a group of bucket chains, bucket plates, bucket wheels, etc. The bucket chains drive the bucket plates to lift the activated carbon to a high place. The transmission device is composed of a motor, a reducer, etc. The motor drives the reducer to work to make the bucket chain run. The electrical control system is used for electrical control and monitoring of the entire hoist.

Activated carbon for bucket elevator has the following features and advantages: Sturdy structure: The equipment is made of high-quality steel with a compact structure and can withstand large loads and gravity impacts. High conveying efficiency: The bucket conveyor conveys materials in the form of buckets, has a large carrying capacity, and can convey materials quickly and efficiently. Strong adaptability: Activated carbon for bucket elevator is suitable for the transportation of various coal, ore and granular materials, and has a wide range of application scenarios. Stable operation: The equipment adopts advanced transmission and bearings, which can maintain smooth and stable operation and reduce energy consumption and maintenance costs. Easy to operate: The activated carbon for bucket elevator is easy to operate and can be controlled through the control panel or remote control, which improves work efficiency and safety.

However, activated carbon for bucket elevator also has some shortcomings. First, it occupies a large area and is inconvenient to arrange. The second is that the noise is large, which has a certain impact on the working environment. The 3rd, energy consumption is higher, and energy consumption is bigger. Fourth, operators need to have certain safety awareness and skills to avoid accidents.

In order to solve the above problems, when manufacturing the activated carbon for bucket elevator, the volume of the machine body can be reduced as much as possible to save the occupied area. When designing, optimize the transmission device to reduce noise and energy consumption. In addition, strengthen the training and education of operators to improve their safety awareness and skills. In addition, regularly maintain and maintain the hoist to ensure its good working condition and reduce the possibility of accidents.

To sum up, the activated carbon for bucket elevator is an important carbon powder handling equipment, which has certain advantages and disadvantages. During use, it is necessary to pay attention to safe operation, arrange the machine reasonably, and perform regular maintenance to ensure the normal operation of the hoist and improve work efficiency.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.