It is very important to choose the right vibro sifter. Here are some factors to consider when choosing a vibro sifter:

1. Characteristics of screening materials

When selecting a vibro sifter, the characteristics of the material to be screened should be considered, including the content of the material under the sieve, the content of the difficult-to-sieve particle size, the moisture content of the material, the shape and specific gravity of the material, and the content of clay and other characteristics.

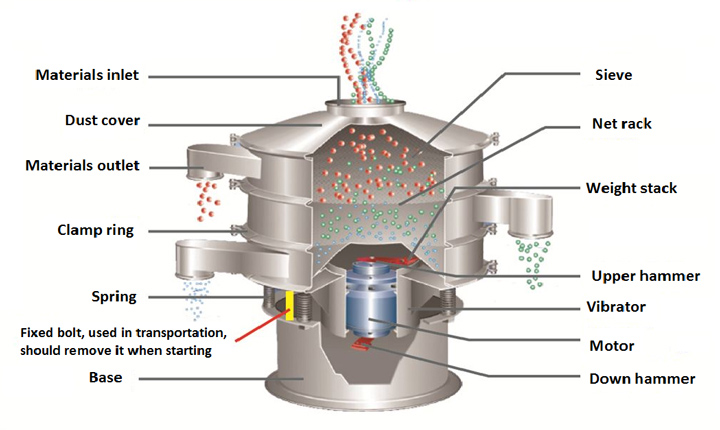

2. The structure of vibro sifter

When choosing a vibro sifter, the screen area, the number of layers, the shape, size and area ratio of the vibro sifter, as well as the movement mode, vibration frequency and amplitude of the vibro sifter should also be considered. The screening efficiency of vibro sifter is related to the movement form of the screen surface, so the screening efficiency of the fixed screen is low, and the screening efficiency of the moving screen is relatively high. For the moving screen, the vibration of the particles on the screen surface is close to the direction of the vertical screen holes, the vibration frequency is high, and the screening effect is better; if the particles slide in the direction of the screen surface, the screening effect is relatively poor.

3. Purpose of use

According to different screening purposes, different vibro sifter types need to be selected, such as:

If the material needs to be pre-screened, a circular vibrating screen is generally used; for the classification and screening of the crushed material, a large vibro sifter, a probability screen, etc. are used; for de-intermediation and dehydration treatment of the material, it is better to choose a dewatering screen; The material is used for desilting and sand cleaning, and a probability screen is used.

4. Requirements for use environment

Different production environments also affect the selection of vibro sifter. Space requirements, installation location requirements, etc. can affect the size and output of the screen machine.

Note: The production space determines the width and height of the screen machine, and the width and height of the screen machine are the main factors affecting the output.

5. Process requirements

When choosing a vibro sifter, it is also necessary to consider the processing capacity of the production line, the screening method, the screening efficiency and the inclination angle of the vibro sifter.

In the actual production of machine-made sand, it is necessary to select the largest sieve size and effective screening area as much as possible according to the actual situation and meet the requirements of the particle size of machine-made sand products, and select the appropriate sieve shape and screen surface opening. High-efficiency non-metal screen surface to improve the screening effect and work efficiency of sand and gravel materials.

Reasonable selection of vibro sifter can effectively improve production efficiency and product quality. If you have any questions when purchasing vibro sifter, please contact us.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.