![]()

![]()

![]()

Price:$40.00-$500.00/Set

Consult now and enjoy a 10% discount

Model: YZO

Exciting force: 1.5-75KN

Power: 0.15-5.5KW

Vibration acceleration: no more than 7g (g: acceleration of gravity)

Ambient temperature: no more than 40°C

Altitude: no more than 1000m

Power frequency: 50HZ

Voltage: 380v

Application: It is an ideal excitation source for mechanized screening, conveying, crushing, filling and anti-clogging of powdery, granular, blocky and other bulk materials. This machine can be used alone or in combination with multiple machines.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

YZO vibration motor is a type of vertical vibration motor that is commonly used in various industrial applications, such as vibrating screens, conveyors, feeders, and sieves. It is designed to produce controlled vibrations along a vertical axis and is often used to move, sort, or separate materials.

The YZO vibration motor is available in a variety of sizes and power ratings to suit different applications. It is typically made with high-quality materials, such as cast iron or aluminum alloy, to ensure durability and long service life. The motor is also designed with a unique bearing structure that reduces noise and vibration and increases efficiency.

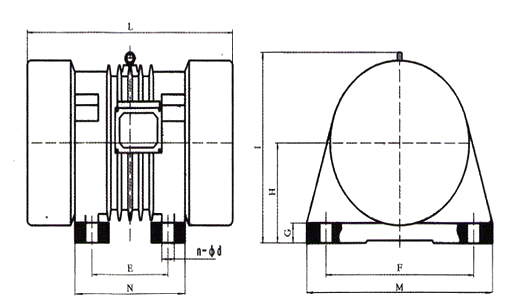

| Model | Force (KN) |

Power (kw) |

Current (A) |

Speed (r/min) |

Mounting dimensions | Weight (Kg) |

|||||||||

| E | F | G | H | I | L | M | N | n | φd | ||||||

| YZO-1.5-2 | 1.5 | 0.15 | 0.35 | 3000 | 180 | 124 | 30 | 82 | 203 | 300 | 210 | 150 | 4 | 10 | 19 |

| YZO-2.5-2 | 2.5 | 0.25 | 0.58 | 180 | 150 | 25 | 82 | 198 | 328 | 220 | 178 | 4 | 12 | 24 | |

| YZO-5-2 | 5 | 0.4 | 1.15 | 220 | 176 | 35 | 91 | 26 | 362 | 270 | 208 | 4 | 14 | 37 | |

| YZO-8-2 | 8 | 0.75 | 1.84 | 236 | 180 | 30 | 142 | 301 | 427 | 292 | 247 | 4 | 18 | 53 | |

| YZO-16-2 | 16 | 1.5 | 3.84 | 236 | 200 | 30 | 142 | 301 | 451 | 292 | 267 | 4 | 18 | 75 | |

| YZO-2.5-4 | 25 | 0.25 | 0.58 | 1500 | 180 | 150 | 25 | 82 | 198 | 328 | 220 | 178 | 4 | 12 | 27 |

| YZO-5-4 | 5 | 0.4 | 1.15 | 220 | 176 | 35 | 91 | 216 | 388 | 270 | 208 | 4 | 14 | 43 | |

| YZO-8-4 | 8 | 0.75 | 1.84 | 236 | 180 | 30 | 142 | 301 | 427 | 292 | 247 | 4 | 18 | 61 | |

| YZO-10-4 | 10 | 1 | 2.3 | 236 | 180 | 30 | 142 | 301 | 473 | 292 | 247 | 4 | 18 | 75 | |

| YZO-17-4 | 17 | 0.75 | 1.8 | 260 | 150 | 25 | 135 | 350 | 420 | 320 | 240 | 4 | 27 | 78 | |

| YZO-20-4 | 20 | 2 | 4.1 | 270 | 224 | 30 | 163 | 370 | 525 | 330 | 298 | 4 | 20 | 135 | |

| YZO-30-4 | 30 | 2.5 | 5.75 | 326 | 184 | 35 | 195 | 425 | 530 | 400 | 306 | 4 | 30 | 168 | |

| YZO-50-4 | 50 | 3.7 | 7.4 | 326 | 184 | 35 | 195 | 425 | 530 | 400 | 306 | 4 | 30 | 180 | |

| YZO-75-4 | 75 | 5.5 | 11 | 440 | 248 | 37 | 240 | 512 | 650 | 530 | 400 | 4 | 36 | 350 | |

| YZO-5-6 | 5 | 0.4 | 1.15 | 1000 | 220 | 176 | 35 | 91 | 216 | 388 | 270 | 216 | 4 | 14 | 48 |

| YZO-8-6 | 8 | 0.75 | 1.84 | 236 | 180 | 30 | 142 | 301 | 471 | 292 | 247 | 4 | 18 | 65 | |

| YZO-10-6 | 10 | 0.75 | 2.3 | 236 | 180 | 30 | 142 | 301 | 473 | 292 | 247 | 4 | 18 | 80 | |

| YZO-12-6 | 12 | 1 | 2.1 | 260 | 150 | 25 | 135 | 350 | 420 | 320 | 240 | 4 | 27 | 82 | |

| YZO-20-6 | 20 | 2 | 4.1 | 270 | 224 | 30 | 163 | 370 | 520 | 330 | 298 | 4 | 20 | 142 | |

| YZO-30-6 | 30 | 2.5 | 5.75 | 326 | 184 | 35 | 195 | 425 | 530 | 400 | 306 | 4 | 30 | 180 | |

| YZO-50-6 | 50 | 3.7 | 7.4 | 326 | 184 | 35 | 195 | 425 | 550 | 400 | 300 | 4 | 30 | 200 | |

| YZO-75-6 | 75 | 5.5 | 11 | 440 | 248 | 37 | 240 | 512 | 650 | 530 | 400 | 4 | 36 | 370 | |

YZO Vibration Motor Model Description

YZO series vibration motor model (as an example) consists of three parts

YZO-5-6

YZO --- vibration motor

5 --- maximum excitation force (kN)

6 --- Poles

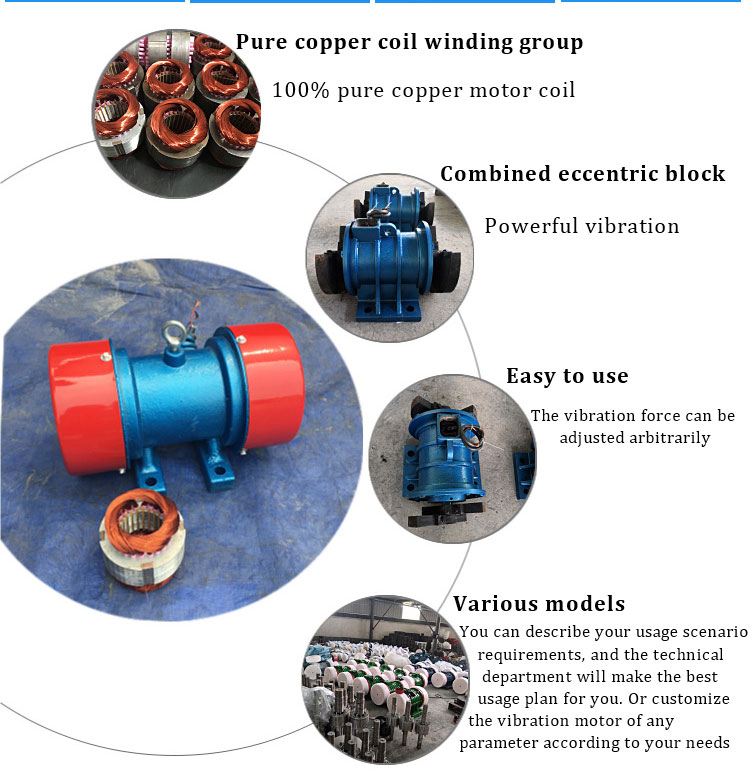

1. High efficiency and energy saving: Compared with traditional motors, YZO vibration motors use vibration power, which has the characteristics of low energy consumption and high efficiency.

2. Reliable and durable: the product is made of high-quality materials, with firm structure and long service life.

3. Easy to operate: the product is easy to operate. It is only necessary to carry out wiring and debugging according to the specified electrical parameters and mechanical parameters.

4. Easy maintenance: The vibration device adopts a modular design, which is very convenient for replacement and maintenance.

5. High adaptability: The product is suitable for a variety of working conditions and has a wide range of applications.

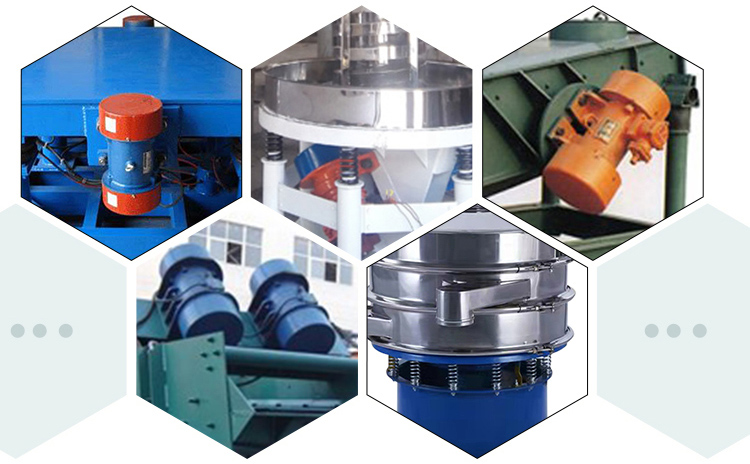

YZO vibration motor is widely used in hydropower construction, thermal power generation, construction, building materials, chemical industry, mining, coal, metallurgy, light industry and other industrial sectors. In addition to being applicable to general vibration machinery, vibration motors can also combine various vibration forms. Such as: flat rotation type, vortex type, shaking vibration type, combined linear type, combined long ellipse type, compound double frequency type, compound double width type, etc. These vibration forms can produce some new vibration machines that did not exist in the past.

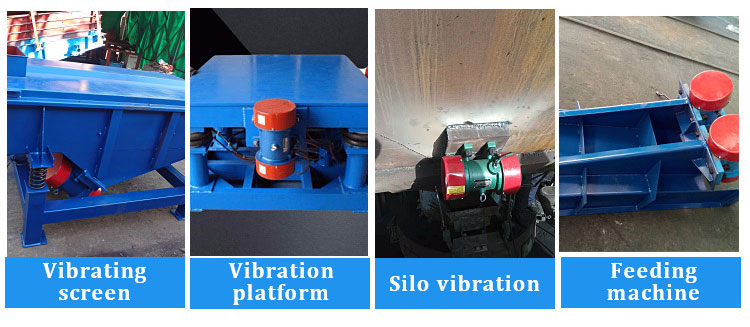

Supporting equipment:

Linear vibrating screen, rotary vibrating screen, swinging screen, straight row screen, circular vibrating screen, mining vibrating screen.

You can choose from the corresponding models according to the required vibration force, vibration frequency, power frequency, motor speed and other factors. For example, YZO-20-6, where 20 means that the vibration force is 20kN, and 6 means that the number of belt channels is 6.

1. A solid machine base and high-quality auxiliary machinery (such as shock absorbers and hooks) are required.

2. The ambient temperature should be between -20℃~+40℃, and the humidity should be less than 90%.

3. The vibrating part needs to be inspected and cleaned regularly, and appropriate protective measures should be selected according to the working environment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.