For all kinds of vibrating screen, conveyor equipment to provide power

![]()

![]()

![]()

Price:$40.00-$500.00/Set

Consult now and enjoy a 10% discount

Model: YZU, YZS, YZUL, YZO

Speed: 750~3000Rpm Series: 2, 4, 6

Rated voltage: 380V Rated frequency: 50HZ

Protection class: IP55 Insulation class: B or F

Ambient temperature: ≤40 ° C Installation direction: Any direction

Application: Used in the drive of vibration equipment, such as vibration feeder, vibrating screen, vibrating conveyor, etc., are the use of vibration motor as a driving source. In addition, the vibration motor can also be used in mixing equipment, fluidized bed equipment and other fields to achieve the full mixing of materials.

Vibration motor, also called electric vibrator motor, vibration screen motor, vibrating sieve motor, is an excitation source that combines power source and vibration source. The centrifugal force generated by the high-speed rotation of the eccentric block obtains the exciting force. The vibration motor has high utilization rate of exciting force, low energy consumption, low noise and long life. The excitation force of the Vibration motor can be adjusted steplessly, which is easy to use and can be applied to general vibration machinery.

Vibration motor models include YZS, YZU, YZO, YZUL, YZD, JZO, VB, XVM, etc. It can work under any dust conditions without explosion-proof requirements. The protection level is divided into IP44, IP54, IP55, etc., and the insulation level is B or F. Working conditions: below 1000 meters above sea level, ambient temperature -15 ~ +40 ℃.

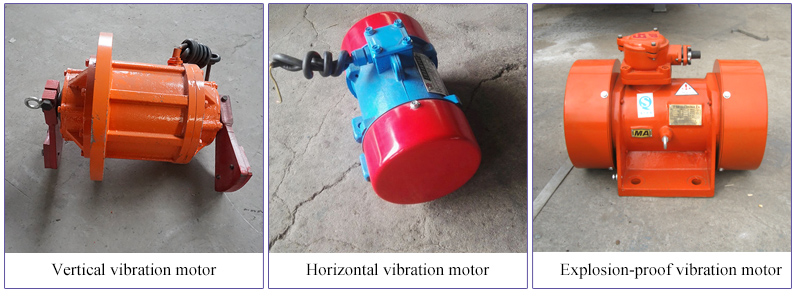

1.Vertical vibration motor: generally YZUL vibration motor, the single flange structure makes the motor easy to install and maintain, reduces the weight of the host, reduces the cost of the host, and the host can handle more materials, and the angle of the eccentric block can be adjusted without poles. Adjust the exciting force to meet various operational needs. It can be used in vibro sifter, ultrasonic vibrating screen, filter sieve and other screening equipment.

2.Horizontal vibration motor: the most common is yzu type, but also yzs, yzo and other models, the exciting force can be adjusted steplessly, easy to use, fully enclosed structure, can work under any dust conditions without explosion-proof requirements, according to different Use Select vibration frequency and amplitude. Generally used in vibrating machinery of linear vibrating screen, direct discharge sifter and vibration table.

3. Explosion-proof vibration motor: The electrical parts that may generate sparks, arcs and high temperatures are tightly isolated from the surrounding explosive gas by using a flame-proof casing, and no electric sparks are generated during operation. It can be widely used in coal mines, oil and natural gas, petrochemical and Hazardous places with flammable and explosive gases such as chemical industry.

| YZU Horizontal Vibration Motor | |||

| Model | Power(KW) | Series | Exciting force |

| YZU3-4 | 0.18 | 4 | 3 |

| YZU5-4 | 0.25 | 5 | |

| YZU8-4 | 0.55 | 8 | |

| YZU10-4 | 0.75 | 10 | |

| YZU15-4 | 1.10 | 15 | |

| YZU30-4 | 1.50 | 30 | |

| YZU50-4 | 2.20 | 50 | |

| YZUL Vertical Vibration Motor | ||||

| Model | Power(kw) | Maximum excitation force(N) | Synchronous speed(r/min) | Current(A) |

| YZULL-5-2 | 0.37 | 5000 | 3000 | 1 |

| YZULL-8-2 | 0.55 | 8000 | 3000 | 1.4 |

| YZULL-10-2 | 0.75 | 10000 | 3000 | 1.7 |

| YZULL-15-2 | 1.1 | 15000 | 3000 | 2.3 |

| YZULL-10-4 | 0.75 | 10000 | 1500 | 1.9 |

| YZULL-15-4 | 1.1 | 15000 | 1500 | 2.6 |

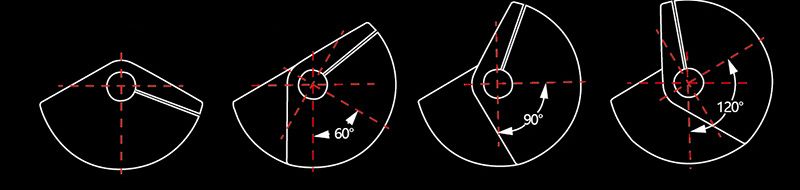

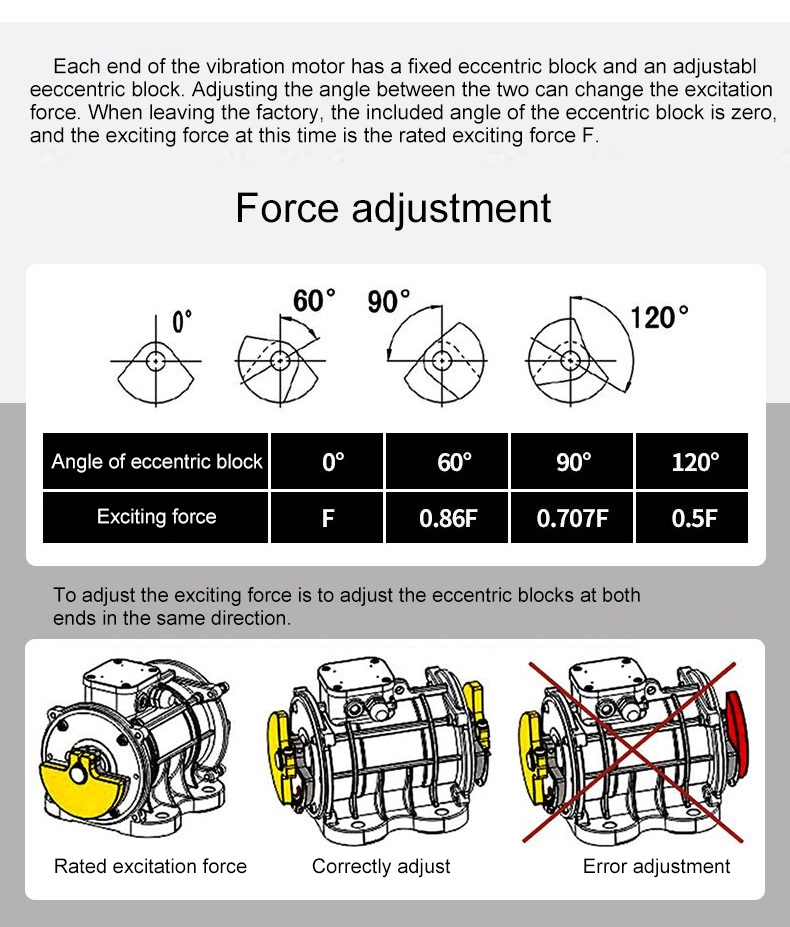

Vibration motor installs a set of adjustable eccentric blocks on both ends of the rotor shaft, and uses the centrifugal force generated by the high-speed rotation of the shaft and the eccentric blocks to obtain the exciting force. The exciting force generated by the eccentric block is transmitted to the vibration machine through the motor. The vibration motor only needs to adjust the outer eccentric block to form a certain angle with the inner eccentric block, and the exciting force can be adjusted steplessly.

1. The excitation force and power are properly matched, the vibration force is large, the body is light in weight, small in size and low in mechanical noise.

2. Because the vibration motor is a strong resistance type vibration instead of resonance, it has a stable amplitude.

3. Multi-machine combination can realize self-synchronization and can complete different process requirements.

4. The direction of the exciting force can be changed according to the installation method of the vibration motor.

5. The exciting force and amplitude can be adjusted steplessly just by adjusting the included angle of the eccentric block.

6. Complete specifications, can meet the work needs of various types of vibration machinery.

Pure copper coil: The surface is treated by special vacuum dipping, all copper wire, F class insulation treatment, pure hand-wired, safe and secure

Eccentric block: The surface is evenly sprayed with anti-rust paint, and the Angle of eccentric block is adjusted by loosening the fastening bolts to achieve the control of exciting force

Special bearings: Select brand bearings, low noise, wear resistance, Shell No. 3 lithium bearing lubrication, long service life

Protective cover: Q235 steel protective cover is selected to prevent the eccentric block from rotating when the motor is running at high speed

Extended lead: vibration motor has reserved about 1 meter of lead for easy installation. The lead can also be lengthened or shortened according to user's request

Base: Base stiffener, plus ball ground cast iron body. Standard universal mounting hole distance, higher bearing capacity

Designed for water resistant structure

All metal parts on the outer surface are made of stainless steel.

Eccentric Rotating Mass (ERM): A weighted mass is attached off-center to a rotating shaft, creating an unbalanced force that generates vibrations.

Linear Resonant Actuator (LRA): A spring-mass system is employed to produce resonant vibrations, offering higher efficiency and lower noise compared to ERMs.

Vibration motor is a general electric tube that provides power for all kinds of vibrating machinery. It is widely used in vibrating screen, vibrating feeder, vibrating crusher, vibrating platform and other vibrating machinery. It is widely used in mining, metallurgy, coal, food, medicine, chemical industry. , plastics, casting and other industries.

1. Screening equipment: linear vibrating screen, vibro sifter, mining screen, coal washing screen, abrasive screen.

2. Conveying equipment: vibrating conveyor, screw conveyor, vertical vibration hoist.

3. Feeding equipment: vibrating feeder, vibrating hopper machine, vibrating mining machine, vibrating filling machine.

4. Other equipment: vibrating fluidized bed, vibrating platform.

1. Remove the protective covers at both ends, and loosen the compression bolts of the adjustable eccentric blocks at both ends;

2. Synchronously adjust the angle between the adjustable eccentric block and the fixed eccentric block at both ends, so that the required excitation force scale line is aligned with the reference line of the shaft end;

3. Tighten the eccentric block pressing bolt and install the protective cover;

4. Check the power supply to see if there is a phase loss, and run it for 5 minutes with no load;

5. Use a 500-volt megger to measure the insulation resistance, and the value should not be lower than 0.5 megohm;

Installation of Vibration motor's foot holes: The four, six or eight foot bolts of the vibration motor should be high-strength bolts not lower than 8.8 according to the hole diameter. The length of the bolts is determined according to the user's installation situation, and can be securely tightened with a wrench. Secure and adopt anti-loosening measures. After the vibration motor has been run for 10 to 20 minutes, check the bolt tightening torque. Tighten again if necessary.

Each end of the Vibration motor has a fixed eccentric block and an adjustable eccentric block. Adjusting the angle between the adjustable eccentric block and the fixed eccentric block can change the magnitude of the exciting force. The angle of the eccentric block is 0° when it leaves the factory. Let the exciting force be the rated exciting force F.

According to the structure of the vibrating machine itself, obtain the weight G (kg) of the vibration machine, and calculate the required vibration force Fm (N), and then the motor model can be obtained.

Vibration force: Fm=G/g×r×ω2

G: Mass of the eccentric block

g: Gravitational acceleration

r: The distance between the center of mass of the eccentric block and the rotary axis

ω: The rotational angular frequency of the motor

Address:China,Yanjin county forest park gate to the west 1000 meters north road.