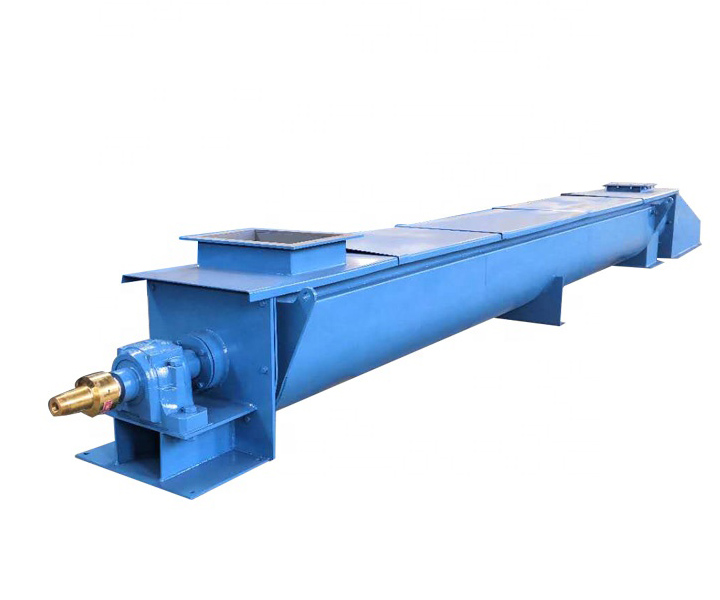

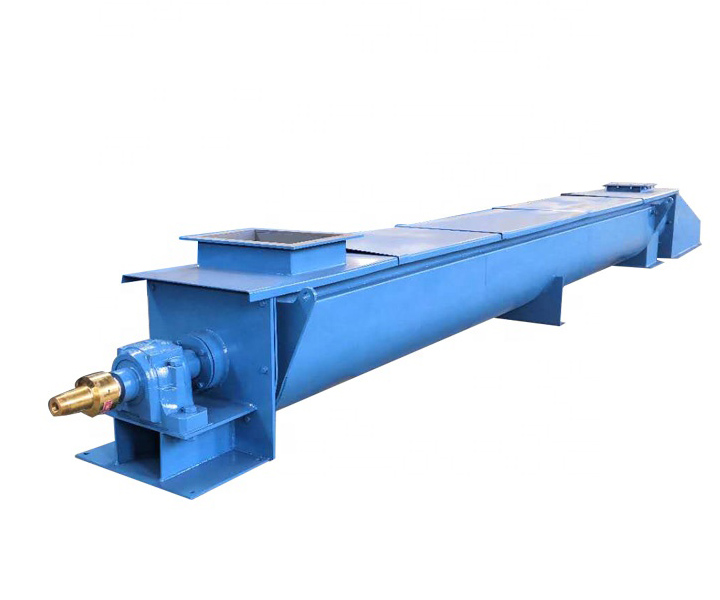

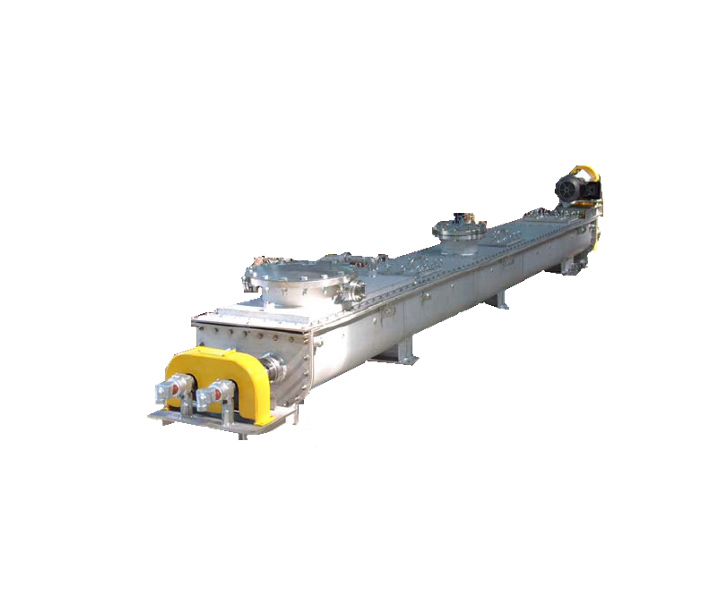

Water cooled screw conveyor

Water cooled screw conveyor Water jacketed screw conveyor

Water jacketed screw conveyor Cooling screw conveyor

Cooling screw conveyor Stainless steel water cooled screw conveyor

Stainless steel water cooled screw conveyor U trough jacket water cooled screw conveyor

U trough jacket water cooled screw conveyor

Suitable for continuous conveying of powder or small particles in high temperature environment (the temperature of the material entering the screw inlet is 450 degrees, and the temperature should drop below 100 degrees when discharging)

![]()

![]()

![]()

Price:$700.00 - $35,000.00/Set

Consult now and enjoy a 10% discount

Spiral diameter: 300-500mm

Material temperature: Input: 450℃ Output: Below 100℃

Water temperature: Input: 40℃ Output: 55℃

Cooling water volume flow/capacity: 71.3m 3 /h

Throughput: 3-10m³/h

Conveying length: 7 meters

Application:incineration system bottom ash handling, high temperature carbon powder in coal chemical industry, pyrolysis residue, flue dust, cement, etc.

Commitment:

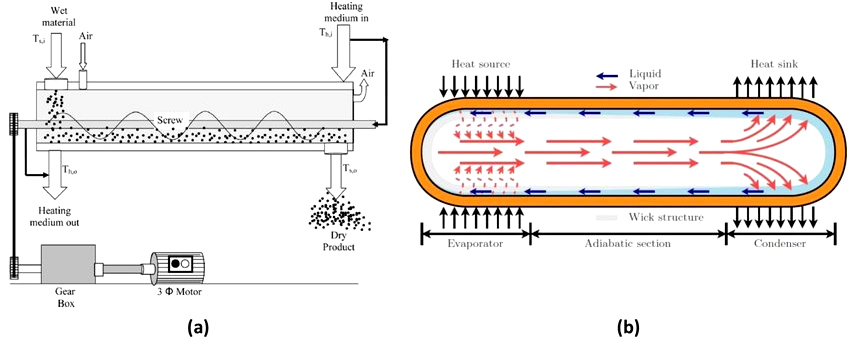

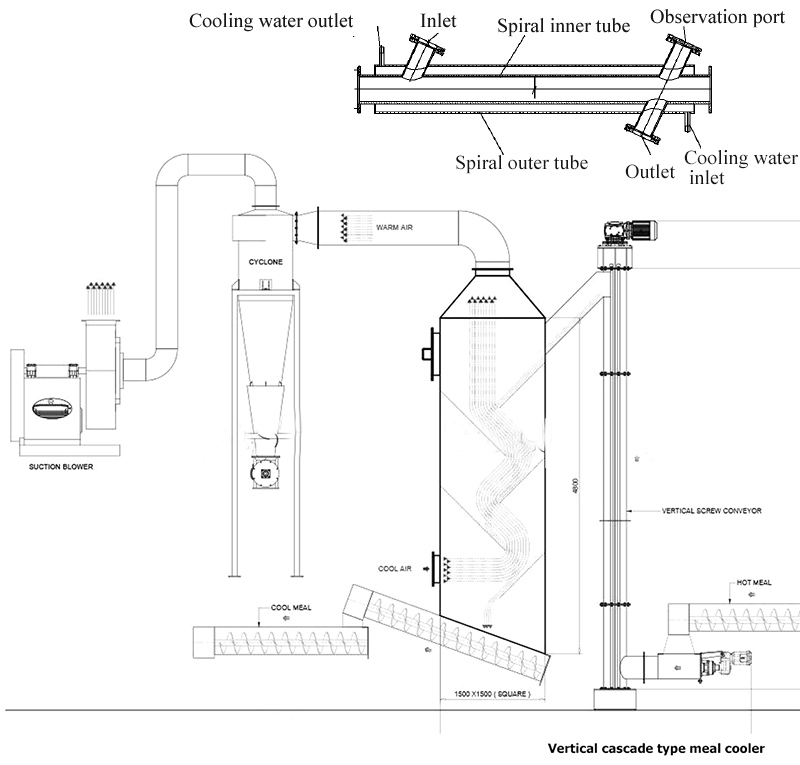

Water cooled screw conveyor, also called jacket cooling screw conveyor, introduces heat transfer medium, such as cold water, hot oil or steam, through special trough jacket and/or the pipes and hollow threads of screw conveyor, and indirectly transfers heat in or out out the product. By calculating the surface area of the auger and designing the system flow to match the heat load requirements of the application, achieving the specified outlet temperature of the product can cool your product from 600 degrees Celsius to below 100 degrees Celsius.

Water cooled screw conveyor is suitable for cooling high temperature materials from 100 degrees Celsius to 600 degrees Celsius. The working pressure of the cooling water is not less than 0.6MP. The cooling effect of the material is achieved by passing water through the screw jacket. The hot steel material solves the problem of exporting and conveying the high temperature charge of 100 to 600 degrees Celsius. Cooling water volume: 4.285t/h (cooling water temperature is 20 degrees Celsius before cooling, and the volume of water required at 100 degrees Celsius after cooling).

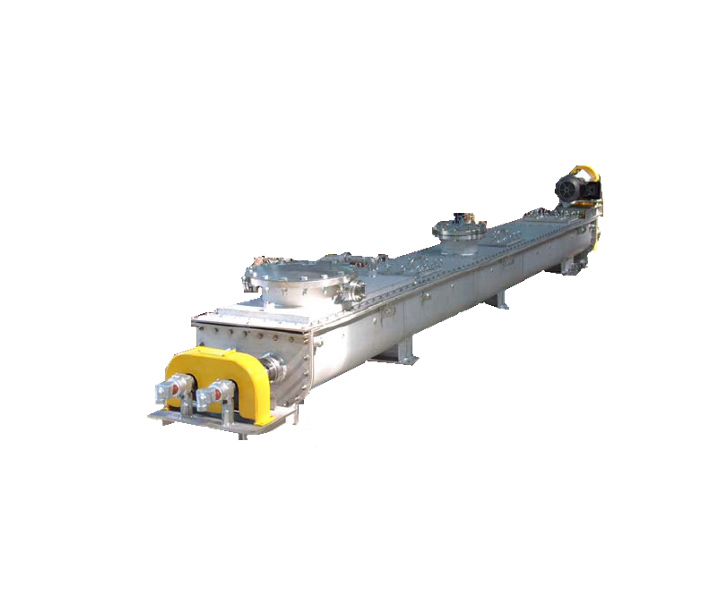

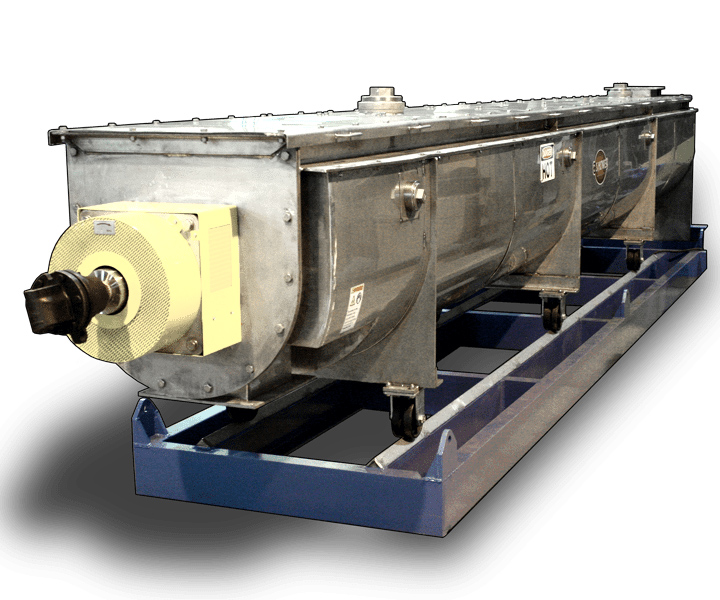

1. Circulating water cooling: a jacket with a certain length is set on the outer cylinder of the machine, and the jacket is equipped with cooling circulating water. Material cooling effect.

2. Internal and external dual cooling: The internal cooling refers to the rotating shaft, which is hollow and can be filled with cold water, and the external cooling refers to the jacket, which can cool the material to a large extent in a large area.

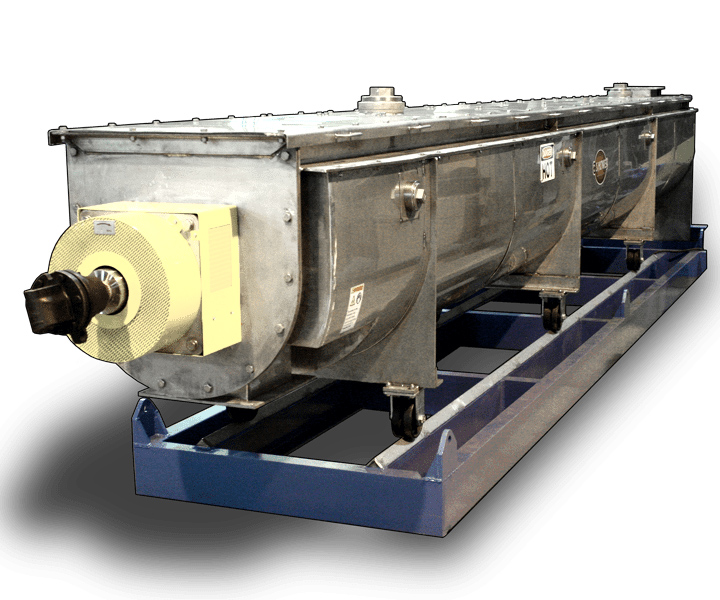

3. The length of the cylinder is the key to cooling: the materials conveyed by the water-cooled screw conveyor are generally freshly burned materials or materials with high temperature themselves, so it takes a certain amount of time during the transportation process. The longer the cylinder length, the better the cooling effect.

Water cooled screw conveyor is a conveying equipment that integrates cooling and conveying. It is equipped with a water cooling system. The cooling water flows from the inlet empty pipe through the spiral plate cavity, and then flows out from the initial empty pipe to form a cooling water channel.

Common applications: cooling fly ash from coal-fired power plant boilers, heating lime for asphalt shingle operations, maintaining a specific temperature for food, cooling drill cuttings from rotary dryers, etc.

Conveying and cooling

The cooling of the material is accomplished by passing water through the screw jacket, which can cool your product from 600 degrees Celsius to below 100 degrees Celsius.

Good cooling effect

The installation height of the equipment is 3300mm, the length is 3000mm, the width is 1100mm. The water pressure is 5kg, the water flow rate is 5T per hour, and the inlet water temperature is 40 degrees.

Large delivery volume

The conveying distance can reach 20 meters, and the multi-machine soft connection can be extended arbitrarily as needed.

Sealing system

It can be fully enclosed for transportation to eliminate dust pollution, and it can also be transported openly.

| Spiral diameter(mm) | 300 | 400 | 500 |

| Pitch(mm) | 300 | 400 | 500 |

| Rotating speed(r/min) | 6 | 7 | 8 |

| Throughput(m3/h) | 3 | 5 | 10 |

| Motor Power(Kw) | 3 | 3-4 | 4 |

| Conveying distance(m) | <7 | <7 | <7 |

| Material temperature(℃) | <800 | <800 | <800 |

| Material proportion(%) | ≈0.8 | ≈0.8 | ≈0.8 |

| Blade material | SU304 | SU304 | SU304 |

| Water pressure(MPa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

| import and export | DN40 | DN40-50 | DN40-50 |

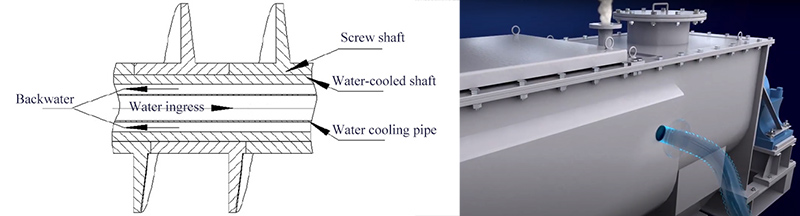

Water cooled screw conveyor consists of screw shaft, water cooling shaft, water cooling pipe and rotary joint.

1)The screw shaft is made of high-temperature and wear-resistant materials, and is made of split screw blades, which can be replaced separately during use.

2)The water-cooling shaft is a hollow structure, made of high-quality steel, and is used as the bearing shaft of the screw body to transmit torque.

3)The water-cooling tube is used for the circulating cooling of the water-cooled shaft, improving the use environment of the shaft and prolonging the service life of the shaft.

When the equipment is in use, the cooling water enters one end of the water-cooling tube through the rotary joint, and flows into the water-cooling shaft after passing through the water-cooling tube, and then the cooling water is discharged through the rotary joint through the water-cooling shaft to realize circulating cooling.

Working system: S1 (continuous working system)

Pressure: 0.6MP (cooling water working pressure);

Cooling temperature: the feed temperature is 720 degrees Celsius, and the discharge temperature is below 150 degrees Celsius

Cooling water velocity: 0.37m/s

Cooling water volume: 4.285t/h (cooling water temperature is 20 degrees Celsius before cooling, and the volume of water required for 100 degrees Celsius after cooling).

The cooling water-cooled screw conveyor is designed for the special working conditions of high-temperature charge transportation. The screw shaft and outer casing are cooled by water. The spiral blade and the screw shaft have a split structure and are made of heat-resistant steel. , delivery problems.

1) Material cooling range: the temperature difference between the maximum temperature and the minimum temperature, so as to design the cooling series, and the length of a single-stage cooling generally does not exceed 7 meters.

2) The temperature of the cooling source: the cooling source temperature of 5 degrees Celsius and the starting temperature of 30 degrees Celsius have different effects on the same equipment design, so you need to provide the necessary data to Xinxiang Dahan Machinery before designing the scheme, so as to design a reasonable water cooling for you Cooling program.

3) Material characteristics: Different materials have different heat dissipation properties. Before ordering equipment, accurate materials must be provided to Chongnuo Liu Chen, so that our company can perform calculus simulation to ensure the cooling effect.

4) Equipment installation space location: it is good for low temperature cooling applications, and the occasions where the cooling range is large requires a large area. To be arranged, it can be arranged horizontally, vertically, or inclined to meet the location requirements.

5) On-site power source: In the design of water-cooled cooling, the ultra-high temperature cooling system is not limited to the form and structure of water-cooled cooling. The Chongnuo design plan will also design composite process structures such as air-cooling and air-cooling.

Address::China,Yanjin county forest park gate to the west 1000 meters north road.