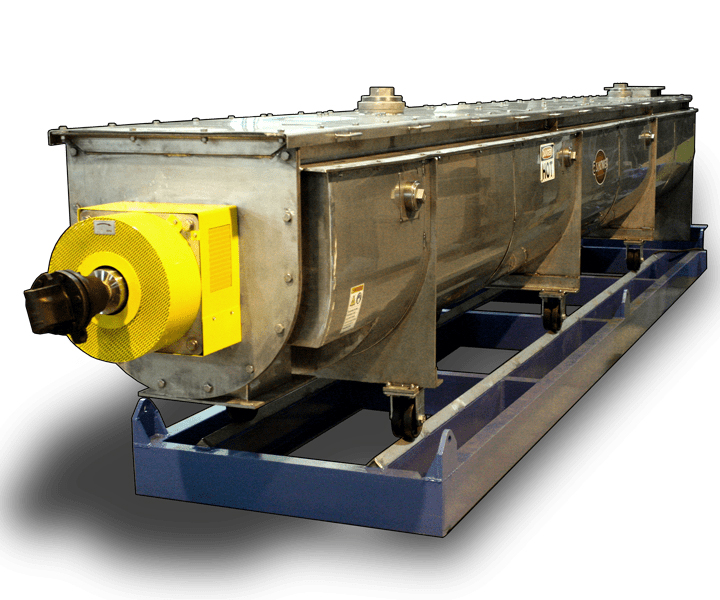

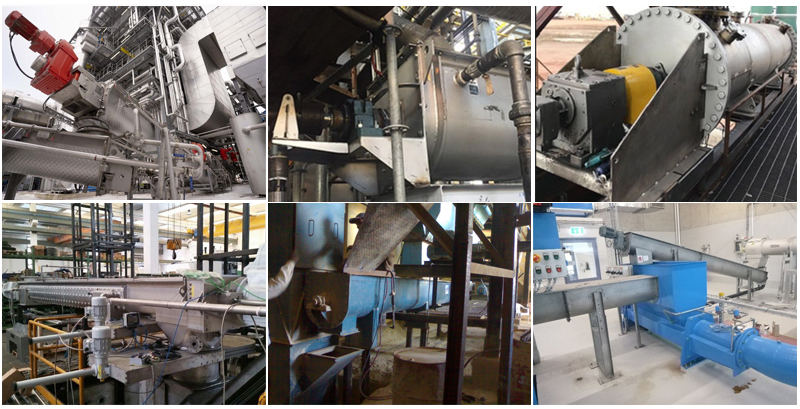

It is used to convey bulk materials at 500℃ high temperature, and can realize heat preservation or cooling during the conveying process.

![]()

![]()

![]()

Price: $550.00 - $35,000.00/Set

Consult now and enjoy a 10% discount

Spiral diameter: 300-500mm

Material temperature: Input: 450℃ Output: Below 100℃

Water temperature: Input: 40℃ Output: 55℃

Cooling water volume flow/capacity: 71.3m 3 /h

Throughput: 3-10m³/h

Conveying length: 7 meters

Application: Used in various industrial applications that require cooling or drying of materials during processing, such as high temperature slag, high temperature fly ash, cinder, carbon black, etc.

Commitment:

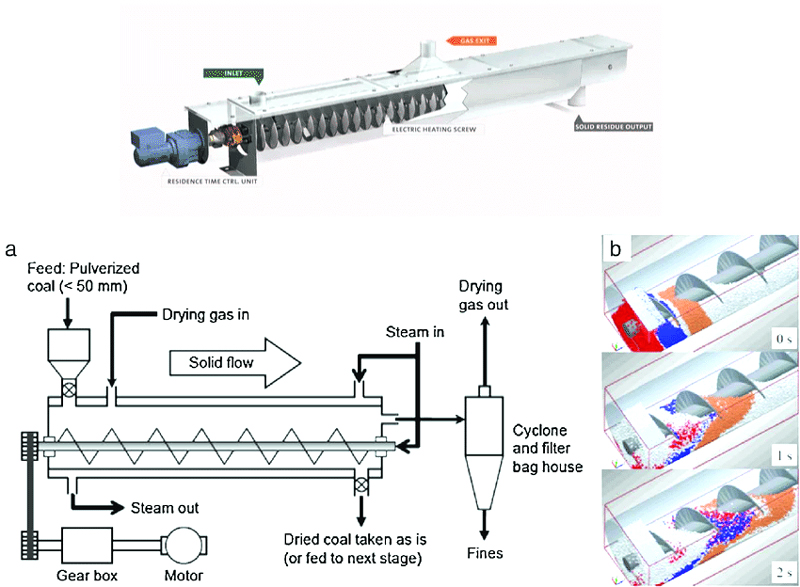

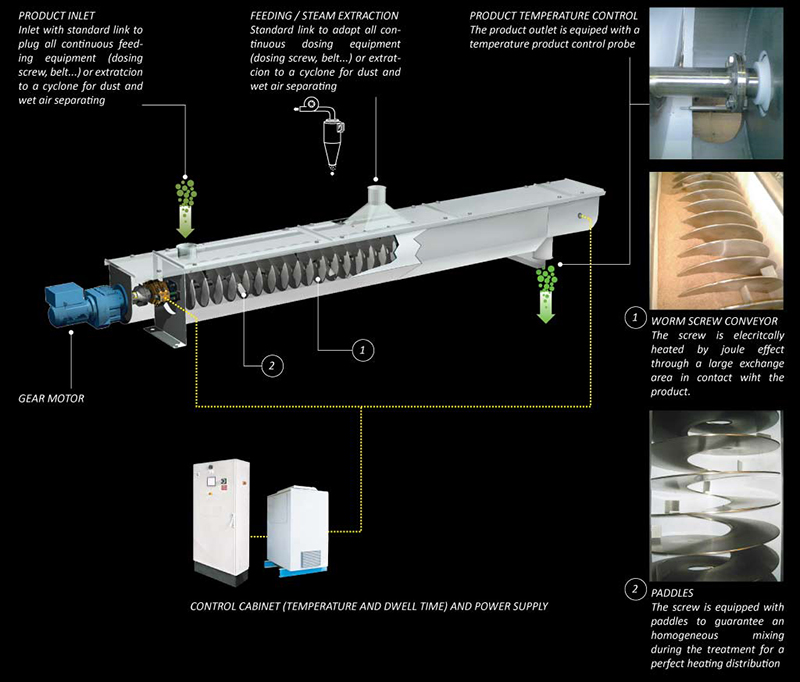

High-Temperature screw conveyor is a conveyor system designed for medium-high temperature (MT series) and high-temperature (HT series) materials, designed to move materials while providing cooling effect, this type of conveyor consists of a hollow screw, the screw Surrounded by a jacket filled with a cooling medium such as water or air. As the material travels along the length of the screw, it is exposed to a cooling medium in the jacket, which helps reduce its temperature. This is especially useful in applications where the material being conveyed generates heat during processing, or requires cooling prior to further processing or packaging.

High-Temperature screw conveyor can cool your products from 600 degrees Celsius to below 100 degrees Celsius, which can meet the feeding and discharging requirements of reclaimed sand in foundries, coal-fired power plants or drying plants, and is generally applicable to bed ash under various conditions , flue dust, sewage slurry, cyanide or pasture.

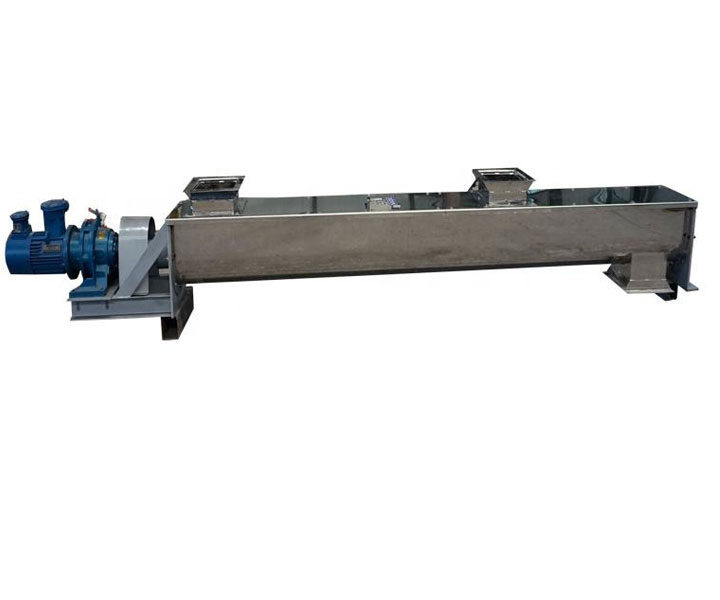

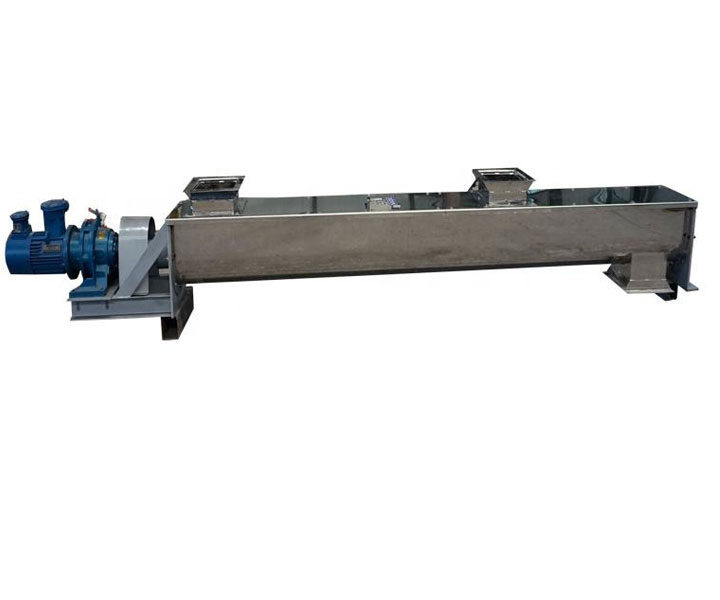

The function of a high-temperature screw conveyor is to transport materials exposed to high temperatures (typically above 200°C (392°F)) from one location to another. Conveyors consist of a screw or auger that rotates within a trough or tube to move material forward. The screws are usually powered by an electric motor, and the conveyor can be inclined or horizontal, depending on the application.

High temperature screw conveyors can perform the following functions:

Conveying Materials: Conveying materials exposed to high temperatures from one location to another. This includes materials such as cement, steel, chemicals and food.

Mixing materials: Used to mix and mix materials during transportation. This is useful for applications where multiple materials need to be combined prior to processing or storage.

Cooling material: It can be designed with cooling jacket or other cooling system to reduce the temperature of the conveying material. This is useful for applications where the material needs to be cooled before processing or storage.

Heating materials: a heating system can be designed to increase the temperature of the conveying materials. This is useful for applications where materials need to be heated prior to processing or storage.

Mixing and reaction of chemicals: used to transport chemicals that need to be mixed or reacted at high temperature. This is useful in chemical processing applications.

High-Temperature Screw Conveyor adopts the principle of hollow spiral and heat exchanger. The hollow design provides space and path for the flow of temperature-adjusting medium. At the same time, during the conveying process, the spiral blade and the screw shaft are constantly rotating and continuous with the material being conveyed. In contact, the hollow helical surface acts as a solid partition to separate the medium from the material being conveyed to form heat exchange. This design provides the High-Temperature Screw Conveyor with the ability to cool, keep warm and even heat the material as needed.

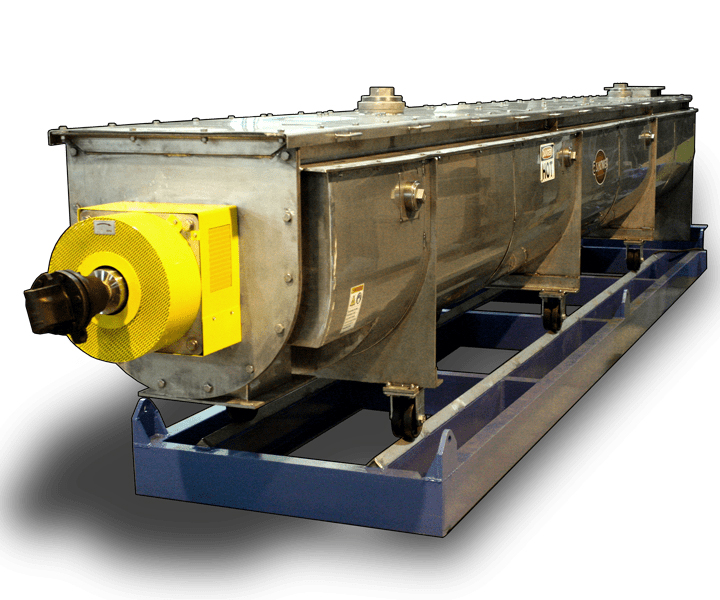

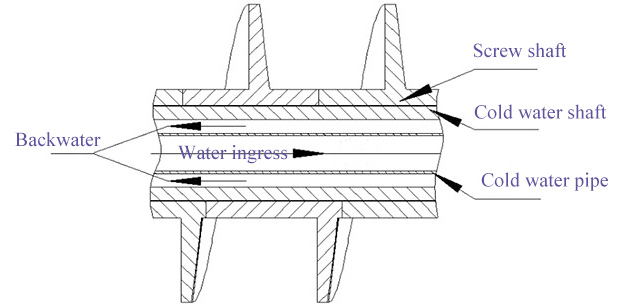

1. Circulating water cooling method: cooling water enters from the screw outlet and flows out from the screw inlet.

Circulating water cooling: The conveying pipe groove of the water-cooled screw conveyor is a sandwich design, equipped with a jacket of a certain length, and the jacket is equipped with cooling circulating water. After the material enters the conveying pipe groove, it rotates and continuously contacts with the cold water jacket to achieve the purpose of cooling.

2. Cooling method: internal cooling (spiral), external cooling (jacket), internal and external dual cooling: internal cooling refers to the screw shaft, hollow design, can be filled with cold water, external cooling refers to the jacket, which can cover a large area of materials, Maximum cooling.

3. The length of the conveying pipe groove is the key to cooling down: the materials conveyed by the water-cooled screw conveyor are generally freshly burned materials or materials with high temperature, so it takes a certain amount of time to drop to the expected temperature during the conveying process. The longer the trough length, the better the cooling effect.

1. Material handling at high temperatures: used to handle materials whose temperature is too high for conventional screw conveyors. , which can cool your product from 600 degrees Celsius to below 100 degrees Celsius. This makes them ideal for applications requiring the movement of materials at extremely high temperatures, such as furnaces, kilns or other high temperature processes.

2. Good cooling effect: the jacket surrounds the conveying pipe or conveying trough, and is filled with cooling medium, such as water or air. This allows the material being conveyed to come into contact with the cold surface of the jacket, which helps reduce its temperature. The large surface area of the conveyor tube or trough allows efficient heat transfer and the cooling effect is evenly distributed along the length of the conveyor.

3. Special materials: made of special materials that can withstand extreme temperatures. For example, screws can be made of materials such as stainless steel, Inconel, or other high-temperature alloys. The trough or housing can also be insulated to help reduce heat loss and prevent damage to conveyor components.

4. Reduced maintenance and downtime: Because high-temperature screw conveyors are designed to handle materials at high temperatures, they are less likely to experience wear or other types of damage. This helps reduce maintenance and downtime, which is especially important in applications where downtime is costly or disruptive.

5. Flexibility: The machine can be customized to handle a variety of materials and temperatures, making it a versatile solution for many different industries and applications.

| Spiral diameter(mm) | 300 | 400 | 500 |

| Pitch(mm) | 300 | 400 | 500 |

| Rotating speed(r/min) | 6 | 7 | 8 |

| Throughput(m3/h) | 3 | 5 | 10 |

| Motor Power(Kw) | 3 | 3-4 | 4 |

| Conveying distance(m) | <7 | <7 | <7 |

| Material temperature(℃) | <800 | <800 | <800 |

| Material proportion(%) | ≈0.8 | ≈0.8 | ≈0.8 |

| Blade material | SU304 | SU304 | SU304 |

| Water pressure(MPa) | 0.4-0.6 | 0.4-0.6 | 0.4-0.6 |

| import and export | DN40 | DN40-50 | DN40-50 |

A high-temperature screw conveyor is used to convey materials exposed to high temperatures (usually above 200°C (392°F)), and its structure generally consists of the following parts:

Screw: The screw or auger is the main component of the conveyor. It is a helical blade that rotates inside a trough or tube to move material forward. Screws are usually made of high temperature resistant materials such as stainless steel or Inconel.

Chute: The trough is the structure that houses the screw and guides the material being conveyed. Tanks are usually made of high temperature resistant materials such as stainless steel or carbon steel.

Bearings: Bearings support the rotating screw so that it rotates smoothly. Bearings must be able to withstand the high temperatures of the materials being transported. Special high temperature bearings may be required.

Drive system: The drive system provides power to the rotating screw. It usually consists of an electric motor and a gearbox.

Sealing system: The sealing system prevents material leakage and keeps the working environment clean. Special high temperature seals may be required to prevent premature failure.

Cooling System: A cooling system may be required to prevent overheating of material or conveyor components. For example, hollow screw designs with cooling jackets are available for heat dissipation.

Safety system: A safety system should be established to prevent accidents or injuries due to the high temperature of the transported materials. This may include temperature sensors, sirens and automatic shutdown systems.

High-temperature screw conveyors are designed for use in industries and applications where materials are exposed to high temperatures (typically above 200°C (392°F)), the following are some common applications of high-temperature screw conveyors:

Cement Production: Used to transport hot clinker from one location to another.

Steel production: High temperature screw conveyors are used to transport hot steel or other metal products in steel mills or other metal processing facilities.

Power Generation: Can be used to convey fly ash, bottom ash or other types of ash produced by power plants.

Chemical Handling: Can be used to transfer chemicals exposed to high temperatures, such as molten sulfur or other high temperature liquids.

Food processing: Can be used to convey food exposed to high temperatures during processing, such as roasted coffee beans or baked goods.

Plastic processing: Can be used to convey plastic pellets or other plastic materials exposed to high temperatures during processing.

Glassmaking: Can be used to transport hot glass in glassmaking facilities.

High-Temperature screw conveyor has a wide range of applications that require cooling of materials during processing. They can be customized to meet specific requirements for temperature control and dehumidification, making them a versatile and effective solution for many different industries.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.