Vibrating sieve machine

Vibrating sieve machine Stainless steel vibrating sieve machine

Stainless steel vibrating sieve machine Dual deck vibrating sieve machine

Dual deck vibrating sieve machine Multilayer vibrating sieve machine

Multilayer vibrating sieve machine Powder vibrating sieve machine

Powder vibrating sieve machine

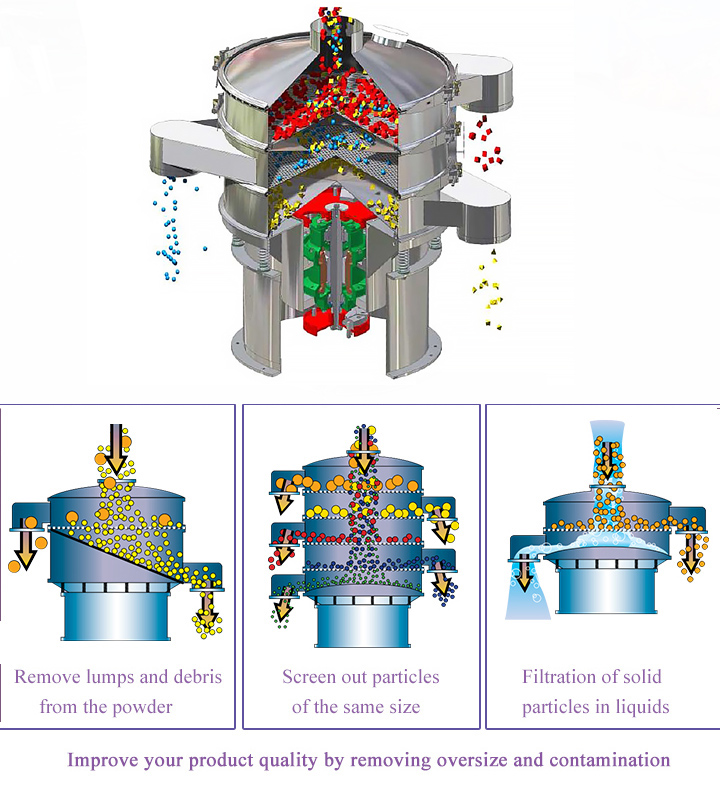

Ideal for screening wet and dry materials, it removes oversize and contamination, improving the quality of your product.

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Diameter: 400/600/800/1000/1200/1500/1800/2000mm

Mesh size: 20-500 mesh

Capacity: 100Kg-10Tons/hour

Material: Stainless Steel 304 and 316L/Q235

Layer(s): 1-5 Layers

Vibrating frequency: 1460r/min

Noise: ≤75db

Cleaning system: Bouncing ball, ultrasonic system, brush

Application: Suitable for dry or wet applications such as silica, ceramics, powder coatings, tapioca, coffee beans, copper powder, silver powder, etc.

Commitment:

Vibrating sieve machine, also called sieve machine, capable of simple safety sieving and precise classification of powders or granules, removes oversized contaminants from products, accurately separates products into 2-6 different sizes, sieves Score up to 500 meshes. The material is separated by a wire mesh, so that smaller particles pass through different mesh widths and larger particles pass through different mesh openings. The separation of large particles can also remove any impurities in the material, and through powerful three-dimensional motion (horizontal, vertical and tilting), the processing capacity is doubled to four times that of conventional machines.

The Vibrating sieve machine allows up to 5 sieves to separate up to 6 different sizes of products, possible diameters: 400, 600, 800, 1000, 1200, 1500, 1800mm, suitable for sieving from 36 microns to 25 mm . A throughput of 100 to 5,000kg/h is allowed, depending on the product, mesh size and feed flow of the machine.

Contact us for more information on our range of vibrating sieve machines and how we can help you with your unique requirements.

Vibrating Sieve

Can remove oversized particles and contaminants as an effective way to protect ingredients and final products from contamination and agglomeration, thereby improving the quality of your products and grading materials based on particle size.

Ultrasonic Vibrating Screen

It is an ultrasonic system added on the basis of ordinary vibrating sieve. It consists of a generator and a probe. The ultrasonic frequency is applied to the sieve, which can prevent the sieve from being blocked and can be accurately separated to 20µm (#635mesh).

Direct Discharge Sifter

It is a rough inspection screening and impurity removal for powders and granules, which is very suitable for screening incoming ingredients and final production inspection of finished products.

1. Removal of impurities: high fluidity powder processing, fast removal of large particles or fine powder with low content.

2. Grading and screening: Continuously select mixed materials of different particle sizes and classify them into different particle size grades. Can be divided into one, two, three, four and so on. What's more, only one operation can continuously filter up to 5 stages of product separation.

3. Solid-liquid separation: quickly remove insoluble solids in various slurries, and remove unqualified impurities or suspended solids in slurries.

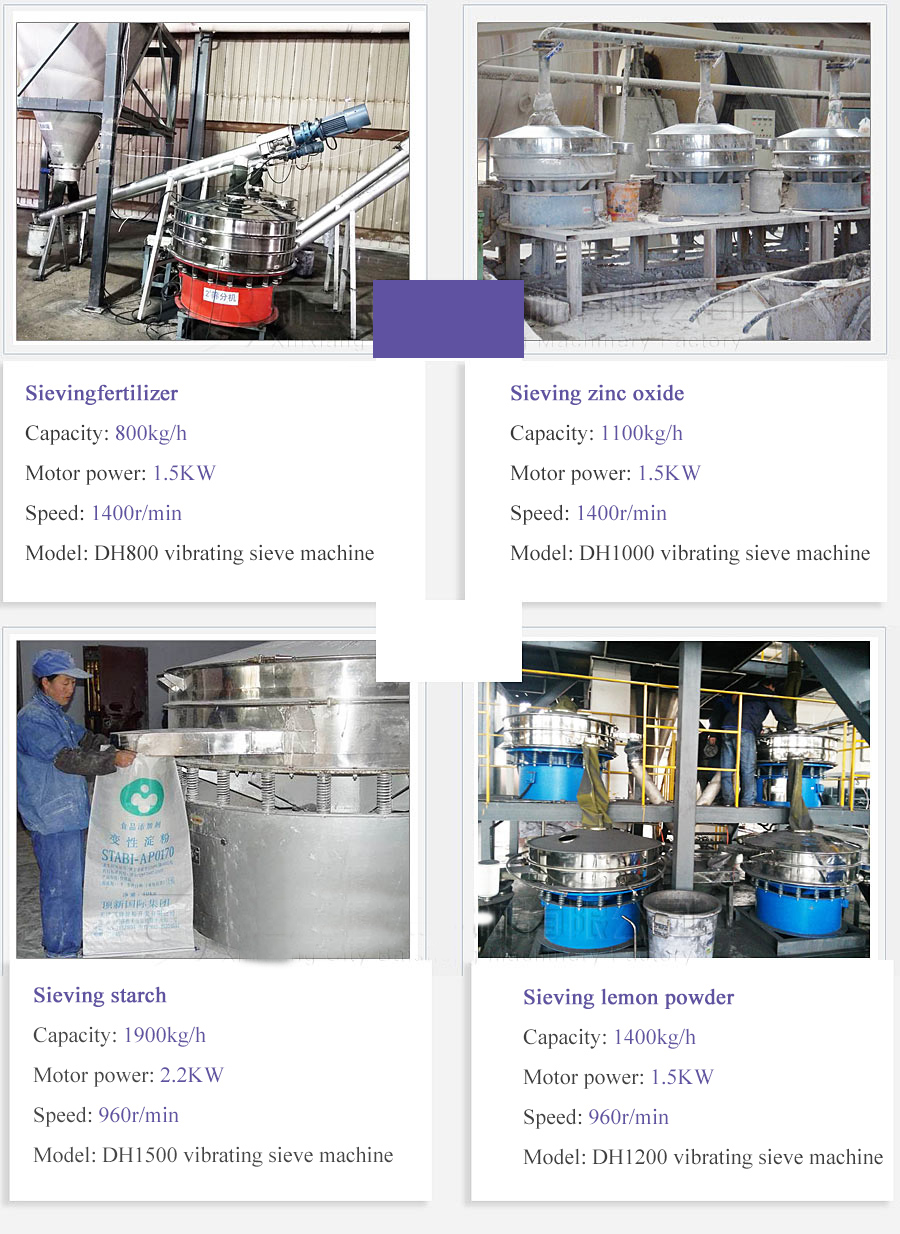

Sieving turmeric powder

Divide corn into different grades

According to different screening requirements, through 1-5 layers of screens with different mesh numbers, in the process, the bouncing balls under each layer of screens continuously hit the screens, so that the materials are smoothly screened and effectively prevent the materials from clogging the screen holes. The material (fine material) close to the screen hole falls under the screen through the screen, and the material (coarse material) larger than the screen hole size stays on the screen surface and is discharged from the discharge port.

Improve product quality

Eliminates oversizing and contamination in powder or liquid slurries, capable of sieving up to 500# to provide accurate particle size

Improve productivity

Provides higher throughput with 3x higher throughput through precise sieving, resulting in high throughput in most applications

Multistage separation

Provides up to 5 levels of classification in one operation for precise particle size distribution

Small footprint

The compact form requires minimal headroom and can easily fit into your existing production line

Eliminate dust and smoke

Closed structure design ensures complete containment of screening material

Reduce noise levels

Rubber suspension system reduces mechanical noise and ensures quiet operation

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

Capacity (kg/h) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 | 100 |

| DH-600 | 600 | 0.25 | 200 | |||

| DH-800 | 800 | 0.55 | 500 | |||

| DH-1000 | 1000 | 0.75 | 800 | |||

| DH-1200 | 1200 | 1.1 | 1200 | |||

| DH-1500 | 1500 | 1.5 | 1800 | |||

| DH-1800 | 1800 | 2.2 | 2000 |

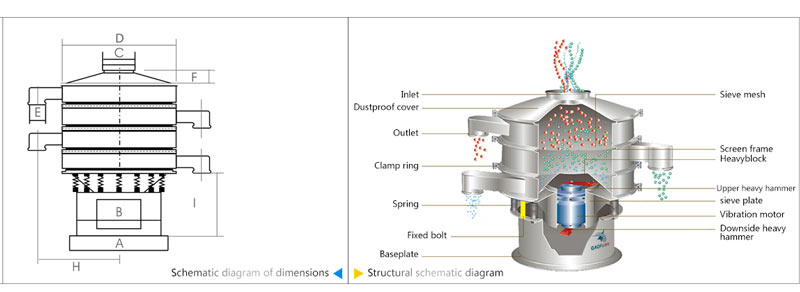

Vibrating sieve machine is composed of dust cover, sieve frame, screen mesh, mesh rack, mesh cleaning device, motor (vibration source), shock absorbing spring, base and other parts.

Dust cover: It is composed of feed inlet and inclined cone, and its lower end is connected with the screen frame to prevent workshop dust from falling into the material when the vibrating screen is working. Commonly used materials are stainless steel, carbon steel and plastic. And so on 3 kinds of materials.

Screen frame: It is rolled and welded by steel plate, with bearing rings at the upper and lower ends, and flange rings inside the lower part, which are used to fix the structure of the screen members.

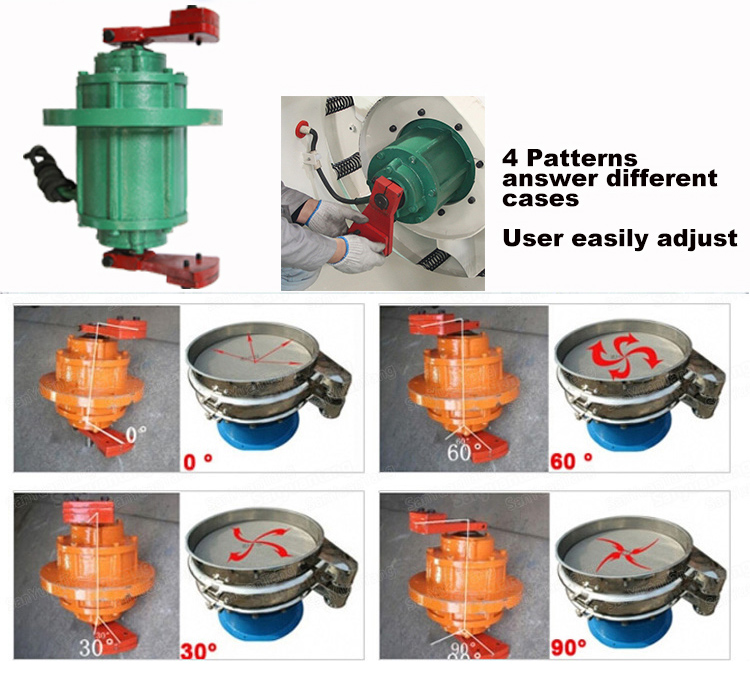

Vibration motor: vertical vibration motor, divided into four specifications: 2, 4, 6, 8, and horizontal. The vibration times are 2870, 1460, 980, and 740RPM respectively. It can be designed as an explosion-proof type (inflammable and explosive occasions)

Screen mesh: models include φ600, 800, 1000, 1200, 1500, 1800, etc., and materials include stainless steel, carbon steel, and plastic.

Cleaning device: clean the clogged materials in the screen mesh to increase the output. It is available in silicone and rubber. You can also choose an ultrasonic cleaning device (635 mesh fine powder with static electricity).

Shock-absorbing springs: There are 12-20 vibration-isolation springs along the vibration transmission body. The base is welded from steel coils. There are access doors and electrical switch housings on the bottom wall. An annular flange is welded on the upper part of the base wall, and the flange is connected with the vibration transmitting body through a vibration isolation spring.

| Normal Type | Edge Type | Gate Type | With Silo Type |

|

|

|

|

| Suitable for screening most powdery materials, the most common model | It is mostly used to filter liquid materials, suitable for a large number of filtration | Special gate design for fine screening, more material in and less out | Intermittent feeding, no need for workers to continuously feed materials, saving labor |

1. Blinding system: you can choose bouncing ball (commonly used particles, powder type below 100 mesh), brush (suitable for spherical materials and crystalline products), ultrasonic deblinding system (suitable for viscous, precise ultra-fine powder), Enables sieving of powders on sieves as fine as 20 microns without clogging or clogging.

2. Sieve deck lift system: Using two high performance pneumatic piston assemblies, multiple sieve decks can be quickly and safely lifted to a height for comfortable access to the sieve decks that need to be inspected or replaced.

3. Quick Release Clamp: An innovative quick release clamp that provides consistent and even clamping pressure. It overcomes the problems associated with frequent readjustment of the lower clamp, providing benefits such as extended life of clamp pads, seals and gaskets, as well as minimizing heat generation and damage to the mating surfaces of the vibrating sieve.

4. Magnetic Separator: Designed to provide the ultimate solution for iron contamination control when inspecting and screening dry powders, it features a unique open design for easy and efficient removal of iron contamination.

5. Bellows and Sleeves: Transfer materials from one machine to another to maintain hygiene and prevent external contamination.

| Food & Medicine industry | Metal, Metallurgy & Mining | ||||||||||

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Wheat starch | 1 | 250 | DH-1200-1S | Wet | 3200 IT | Graphite | 1.2 | 16/40/80 | DH-1000-3S | Dry | 1400㎏ |

| Flour | 0.6 | 24 | DH-1000-1S | Dry | 1500㎏ | Lead powder | 11.34 | 10/80 | DH-1000-2S | Dry | 1000㎏ |

| soy sauce | 1 | 100 | DH-1200-1S | Wet | 6500 IT | Iron powder | 3 | 400 | DH-800-1S | Dry | 230㎏ |

| Salt | 1.2 | 30/80 | DH-1500-1S | Dry | 5000㎏ | Emery | 4 | 60 | DH-1000-1S | Dry | 300㎏ |

| Medicine powder | 0.8 | 80 | DH-800-1S | Dry | 550㎏ | Aluminum powder | 0.9/1.2 | 80/120 | DH-800-2S | Dry | 350㎏ |

| Kiln Industry | Pollution Treatment & Other Industries | ||||||||||

| Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

Materials | Proportion | Mesh | Model | Processing Method | Capacity (kg/hr IT/hr) |

| Spray soil particles | 2 | 10 | DH-1000-1S | Dry | 18000㎏ | Waste water | 1-1.3 | 60 | DH-1000-1S | Wet | 15000IT |

| Mica | 0.8 | 200 | DH-800-1S | Dry | 110㎏ | Dyeing and steaming wastewater | 1 | 150 | DH-1000-1S | Wet | 22000IT |

| Feldspar | 2.5 | 60/100 | DH-1000-2S | Dry | 350㎏ | Waste oil | 0.9 | 100 | DH-1000-1S | Wet | 3800IT |

| Quicklime | 2.5 | 100 | DH-1000-1S | Dry | 480㎏ | ||||||

Dahan Machinery is committed to powder, granule, liquid screening, impurity removal and filtration, providing customers with professional solutions and mature supporting products. The screening range of vibrating sieve machine covers 0-3mm coarse powder, 20-200 mesh fine powder/ Granules, 400-500 mesh ultrafine powder, slurries within 5 microns.

If the manufacturer has passed the ISO/CE quality certification, the manufacturer promises that the quality problem will be refunded in full within 365 days of natural damage, and will be exempted from maintenance for life.

13s online

customer service

2 days customize

solutions

Factory

visiting anytime

1-10 days dispatch

the goods

One week

of installation

2 days of

training

365 days

after-sales online

Project tracking

regularly

2 days provide

maintenance plan

Address::China,Yanjin county forest park gate to the west 1000 meters north road.