Tube vibrating conveyor

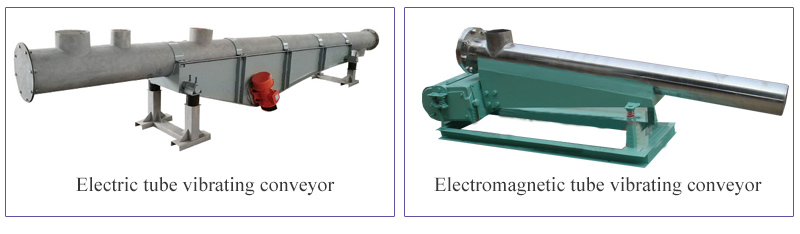

Tube vibrating conveyor Tube vibrating feeder

Tube vibrating feeder Electromagnetic tube vibrating conveyor

Electromagnetic tube vibrating conveyor Stainless steel tube vibrating conveyor

Stainless steel tube vibrating conveyor Tube vibratory conveyor

Tube vibratory conveyor

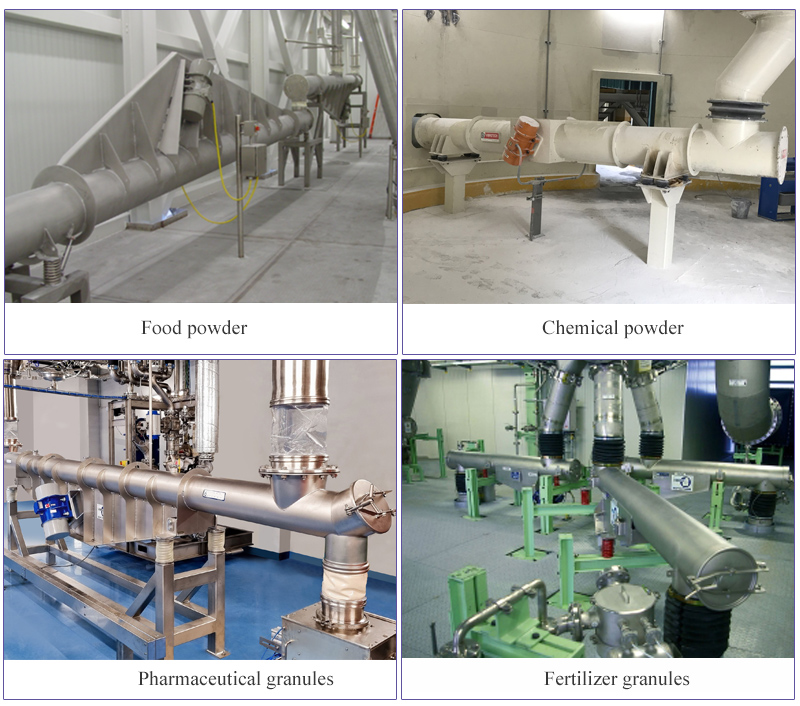

Conveying dusty or brittle dry materials in closed circular ducts for applications with strict hygiene or dust control requirements

![]()

![]()

![]()

Price:$500.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Function: conveying and metering

Type: Motor Drive/Electromagnetic Exciter Drive

Length: 20 feet (6 meters) (when multiple units are used in series, the length can reach 100 feet (30 meters))

Flow rate: high 20 m³/h

Material: mild steel, stainless steel

Angle: 0-5°

Power: 0.25-3kw

Applications: Ideal for controlled discharge of bulk materials from silos, conveying difficult-to-flow or brittle dry solids, and conveying difficult-to-flow or brittle dry solids.

Commitment:

Tube vibrating conveyor is also called tube vibrating feeder, which conveys powder and particles horizontally at a controlled rate in an open or closed environment. The low-speed conveying action is gentle and quiet, with no moving parts in contact with the powder, causing little or no product degradation.

Tube vibrating conveyors can be up to 20 feet (6 meters) in length, and can be connected in series, up to 100 feet (30 meters) in length, and can be driven by motors or electromagnetic exciters, often combined with vibrating screens, belt conveyors, bucket The hoist and other equipment are used together to realize the automatic batching, quantitative packaging, and automatic control process, and the automation of the assembly line can be realized.

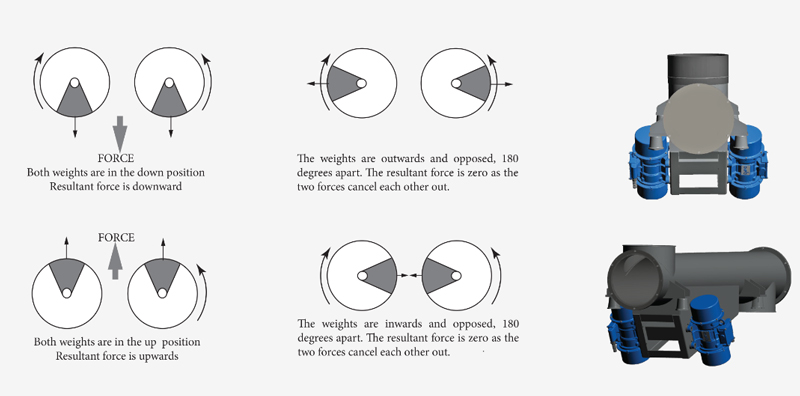

Electric tube vibrating conveyor: Vibration motor is used as excitation source to drive the conveying pipe to work, amplitude: 2-5mm, frequency: 700-3000 times/min, so the structure is simple, the installation and maintenance are convenient, and several conveying pipes can be connected to synchronize It can also realize multi-point feeding and discharging, which is widely used.

Electromagnetic tube vibrating conveyor: The electromagnetic vibrator is used as the vibration source to drive the conveying tube to work. It is characterized by a small amplitude of 1.5-3mm and a frequency of up to 3000 times/min (half-wave rectification) or 1500 times/min (after half-wave rectification). Re-frequency division), so the conveying speed is slow and the precision is high, which can realize the stepless adjustment of the conveying volume, and realize the centralized control and automatic control of the production process.

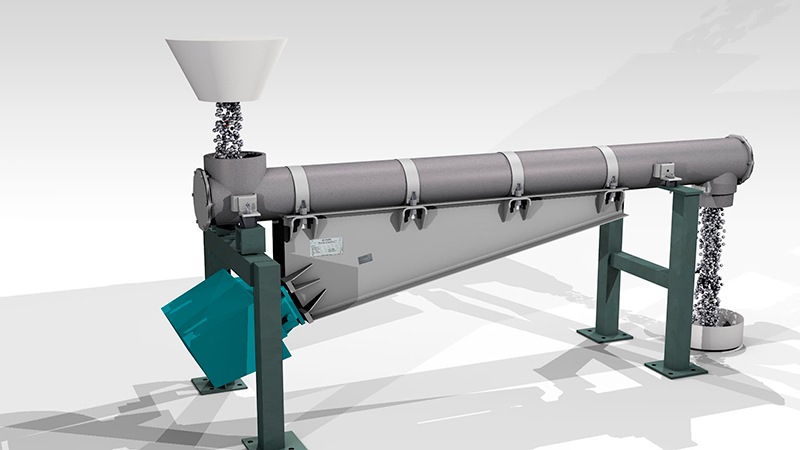

The materials to be transported are fed into the tube or trough of the conveyor.An eccentric vibrating motor is attached to the tube or trough. The motor generates vibrations that are transmitted to the tube through a series of springs.The vibrations cause the tube or trough to oscillate back and forth, creating a wave-like motion. This motion moves the materials forward along the length of the tube. As the materials move along the tube, they may encounter various obstacles such as bends or changes in elevation. The vibrations from the motor help to keep the materials moving smoothly and prevent them from getting stuck or jammed. At the end of the tube, the materials are discharged onto a receiving device such as a conveyor belt, a storage container, or a processing machine.

Long distance transportation

Available in lengths up to 20 feet, or up to 100 feet when connected in series.

Combined installation or multi-point unloading

Several sections of conveying pipes can be connected to convey synchronously, and multi-point feeding and discharging can also be realized.

Dustproof

It is an open or closed design, no dust during the conveying process, and the material is not easy to leak.

Flexible layout

Can be installed on the floor or used in suspended mode, for example under hoppers or silos.

Faster, leaner production lines

It is used in automatic weighing, quantitative packaging and automatic control processes.

Low maintenance cost

Robust and low maintenance design ensures low cost and long product life.

Tube vibrating conveyor for rice

Electromagnetic tube vibrating conveyor for fertilizer

| Model | Tube Diameter (mm) |

Power (kW) |

Angle (°) |

Capacity (T/H) |

Weight |

| DZG20250 | Φ200 | 0.25 | 0~5 | 15-20 | 260 |

| DZG20300 | 0.25 | 15-18 | 280 | ||

| DZG20350 | 0.37 | 15-17 | 300 | ||

| DZG20400 | 0.37 | 10-15 | 320 | ||

| DZG20450 | 0.37 | 10-15 | 350 | ||

| DZG25250 | Φ250 | 0.55 | 20-25 | 300 | |

| DZG25300 | 0.55 | 20-23 | 330 | ||

| DZG25350 | 0.75 | 18-21 | 360 | ||

| DZG25400 | 0.75 | 18-25 | 400 | ||

| DZG25450 | 0.75 | 15-22 | 460 | ||

| DZG25500 | 0.75 | 15-20 | 500 | ||

| DZG32300 | Φ320 | 1.5 | 20-40 | 430 | |

| DZG32350 | 0.75 | 20-35 | 470 | ||

| DZG32400 | 1.5 | 20-30 | 500 | ||

| DZG32450 | 1.5 | 20-25 | 540 | ||

| DZG32500 | 1.5 | 20-45 | 570 | ||

| DZG32600 | 1.5 | 20-35 | 610 | ||

| DZG40400 | Φ400 | 1.5 | 30-60 | 600 | |

| DZG40500 | 1.5 | 30-50 | 670 | ||

| DZG40600 | 2.2 | 30-40 | 740 | ||

| DZG40700 | 2.2 | 30-70 | 1200 | ||

| DZG40600 | 3 | 30-60 | 1400 | ||

| DZG40700 | 3 | 30-55 | 1540 |

| Comparison item | Tube Vibrating Conveyor | Trough vibrating conveyor |

|

|

|

| Shape and design | Round or tubular | Rectangular or trapezoidal |

| Capacity and flow | Typically used in low volume applications | Can handle higher volume applications. Due to its larger surface area, it also tends to have higher flow rates than tubular vibrating conveyors. |

| Maintenance and cleaning | Easier to clean and maintain as they have fewer nooks and crannies for material to get trapped in | May require more frequent cleaning and maintenance due to their more complex design |

| Application | Typically used to convey fragile, viscous or difficult-to-handle materials | For conveying heavier, stronger materials |

| Cost | Simpler designs and lower capacities make them generally less expensive than trough vibratory conveyors, however, the cost of both types of conveyors can vary depending on the specific application, materials of construction, and other factors. | |

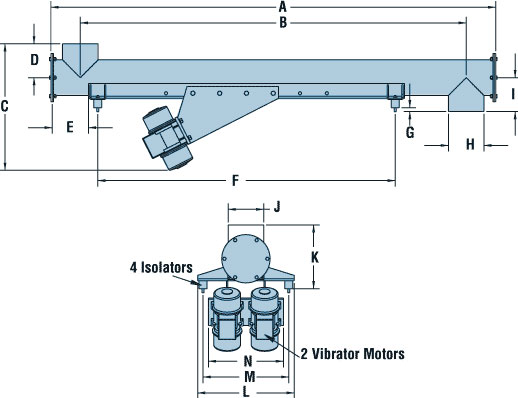

The structure of a tube vibrating conveyor typically consists of several key components that work together to transport materials efficiently and effectively. Here are the main components of a tube vibrating conveyor:

1. Tube or trough: This is the main structure of the conveyor that contains the materials to be transported. It can be made of various materials such as steel, stainless steel, or plastic, and can be designed in various shapes and sizes depending on the specific application.

2. Vibrating motor: This is the power source of the conveyor that generates the vibrations needed to move the materials along the tube. The motor is typically mounted on the outside of the tube or trough and is connected to it through a series of springs.

3. Springs: These are used to transmit the vibrations from the motor to the tube or trough. They help to isolate the motor from the materials being transported and prevent excessive wear and tear on the motor.

4. Support structure: This is the frame or base that supports the entire conveyor system. It is designed to provide stability and to prevent the conveyor from vibrating excessively.

5. Controls: These are the electronic components that control the frequency and amplitude of the vibrations generated by the motor. They can be used to adjust the speed and flow rate of the materials being transported and to ensure that the conveyor operates safely and efficiently.

6. Discharge mechanism: This is the device at the end of the tube or trough that discharges the materials onto a receiving device such as a conveyor belt, a storage container,or a processing machine. It can be designed in various shapes and sizes depending on the specific application.

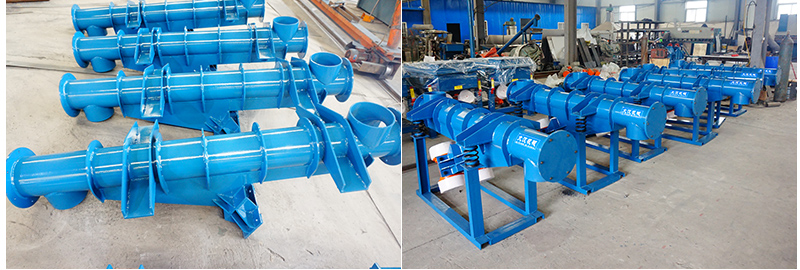

Xinxiang Dahan manufacturers can customize according to user needs:

1.Down-vibration tube vibrating conveyor: The vibrating motor is placed under the conveyor.

2.Vibrating tube vibrating conveyor: The vibrating motor is placed above the feeder.

3.Speed-regulated tube vibrating conveyor: The vibration frequency of the vibration motor can be steplessly regulated within the range of 0-rated frequency.

4.Open type tube vibrating conveyor: The top of the conveyor is open, which is more suitable for the vibration type.

5.Sealed type tube vibrating conveyor: The conveyor is completely sealed except for the inlet and outlet to prevent dust pollution and also protect the conveyed materials from pollution.

6.Pedestal tube vibrating conveyor: For large (heavy) conveyors, a pedestal structure is generally used.

Tube vibrating conveyor is used for feeding powdery, granular and lumpy materials. It uses sealed pipes to convey materials to ensure that the conveyed materials are not polluted. It can be used with vibrating screens, belt conveyors, bucket elevators or crushing The machine is used in conjunction with the process of automatic batching and quantitative packaging. The conveying length of a single machine can reach 10 meters, and multiple machines can be used in series to achieve long-distance conveying. The machine can not only transport all kinds of normal temperature and ordinary materials, but also many unconventional materials such as high temperature and poisonous materials; if special processing is carried out on the carrier, the material screening, drying, heating, cooling and other processes can be realized during the transportation process Require.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.