Vibrating conveyor is an important inertial conveyor, which is used for short-distance and mid-distance conveying of small block, granular and powdery materials. regulated materials. Through special design and process, process requirements such as drying, heating and cooling can be achieved. This article will explain to you several common types of vibrating conveyors.

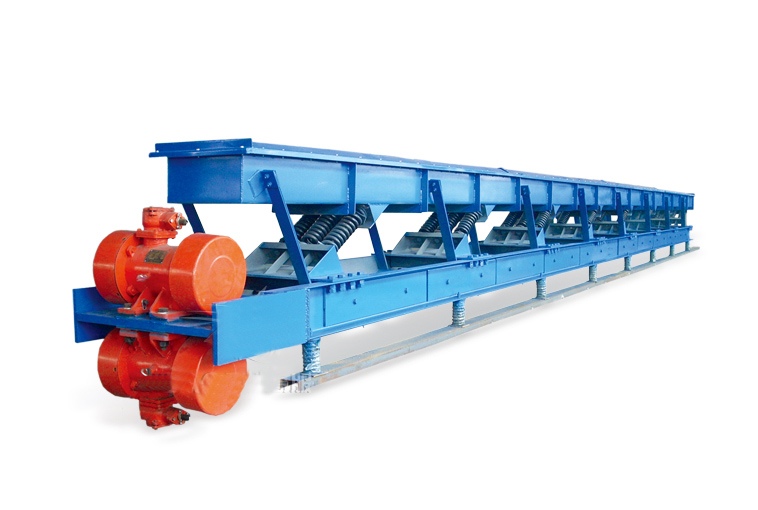

The trough vibrating conveyor (ordinary type vibrating conveyor) uses the vibrating motor as the vibration source, so that the material is thrown up and moved forward, and the reciprocating vibration of the conveying trough conveys the material. side, the length of the conveyor can reach 20 meters, the multi-machine soft connection can be extended arbitrarily as needed, and it can be conveyed upwards ≤10° inclined

The tube vibrating conveyor is used for horizontal conveying of powder and granular materials at a controlled rate in a closed circular tube. Several sections of conveying pipes can be connected for simultaneous conveying, and multi-point feeding and discharging can also be realized. Sealed structure, conveying The length can reach 60-70 meters, and the motor or electromagnetic drive can be selected according to the requirements.

The high temperature resistant vibration conveyor is mainly used for conveying high temperature materials, such as bottom ash treatment of incineration system, high temperature carbon powder of coal chemical industry, coal slag, soot, cement, etc. The material temperature does not exceed 300 degrees Celsius, and the conveying length can reach 20 meters.

The above are several types of vibrating conveyors that we commonly use. In the selection process of vibrating conveyors, we need to consider the properties of materials, space size, conveying length, ambient temperature, dust-proof requirements, etc. Special customized types can be based on actual conditions. selected.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.