Suitable for dosing, extended feeding of weigh boxes or weighed feeders to provide steady, smooth feeding to downstream equipment.

![]()

![]()

![]()

Price:$500.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Type: Electromagnetic Exciter Drive

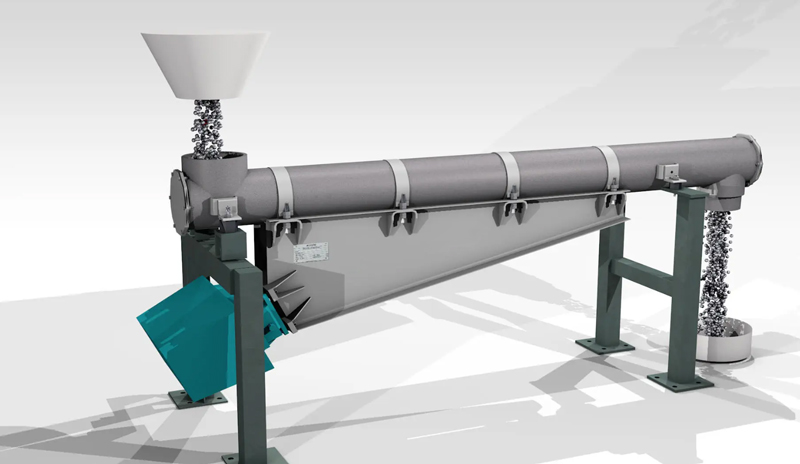

Length: 20 feet (6 meters) (when multiple units are used in series, the length can reach 100 feet (30 meters))

Flow rate: high 20 m³/h

Material: mild steel, stainless steel

Angle: 0-5°

Power: 0.25-3kw

Applications: Commonly used in various industries to convey bulk materials such as powder, granules and small parts. They are especially useful for applications that require gentle handling of materials or conveying fragile or delicate products.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

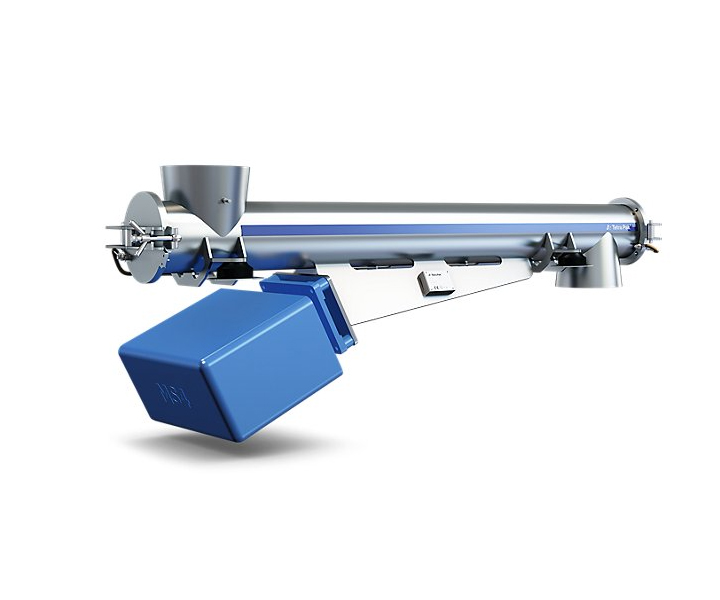

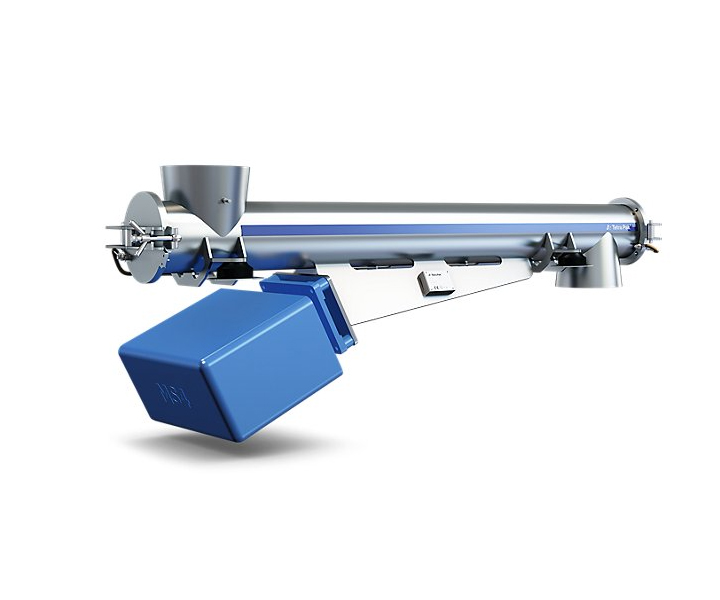

Electromagnetic tube vibrating conveyor is a type of conveying system that uses electromagnetic vibrations to transport materials. It consists of a tubular trough or channel that is mounted on a base and connected to an electromagnetic drive unit.Typically they are used to convey dusty material or used to protect material from ambient conditions. Inlet and outlet can be sealed of by means of elastic sleeves. Applications include dosing, extended feeding of weigh bins, or weigh feeders for steady and smooth feeding for downstream equipment. The tubular configuration allows for a more compact, space-saving setup compared to other conveyor types.

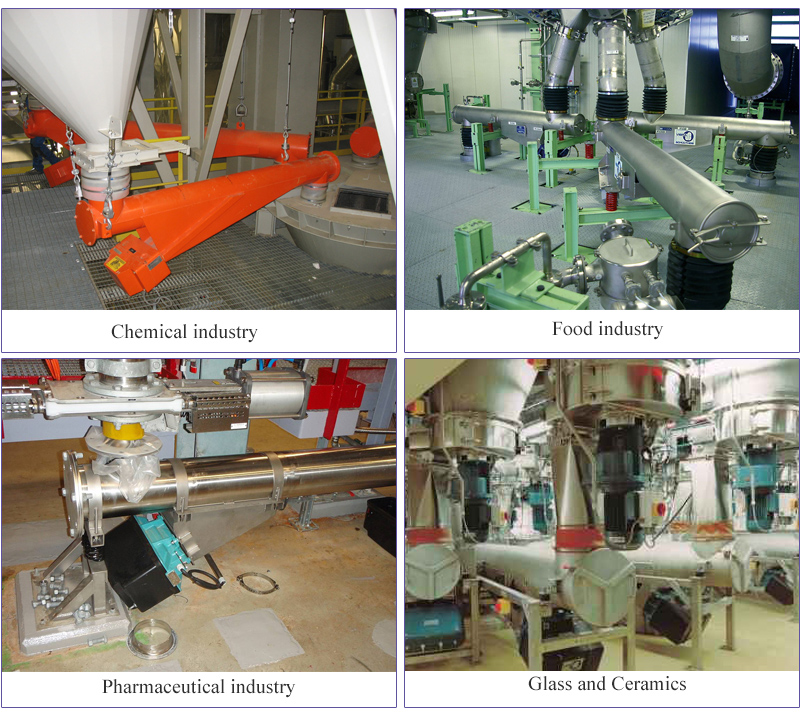

Electromagnetic tube vibrating conveyors are commonly used in various industries for the transportation of bulk materials, such as powders, granules, and small parts. They are particularly suitable for applications where gentle handling of materials is crucial or when conveying fragile or delicate products.

Electromagnetic tube vibrating conveyor is suitable for various industries that require gentle, controlled transportation of bulk materials, some common applications include:

Food Industry: Conveying food such as grains, cereals, nuts, coffee beans and powdered ingredients. Gentle vibrations help prevent product damage and maintain food quality.

Pharmaceutical industry: used to convey delicate tablets, capsules and powders in the pharmaceutical manufacturing process. Precise and controlled movements ensure the integrity of the drug product.

Chemical industry: used to transport granular or powdered chemicals, pigments and additives. Vibration aids material flow and prevents clogging or separation.

Mining and Minerals: For the transportation of ores, minerals and aggregates. They can handle abrasive and heavy materials efficiently.

Recycling: Used to transport recyclable materials such as plastic, glass and paper. Controlled vibration helps to efficiently separate and sort different materials.

Packaging industry: used to transport items such as bottles, containers and cartons. Gentle vibrations facilitate smooth transfer and alignment of packaging materials.

Foundries: transport sand, castings and metal scrap. Vibration helps to separate the sand and mold from the casting.

Recycling Industry: Used to convey materials such as shredded paper, plastic flakes and metal scrap in recycling facilities. Vibration facilitates the separation and sorting of different recyclable materials.

Wood processing: used to transport wood chips, sawdust and other wood products. Vibration aids material flow and prevents clogging.

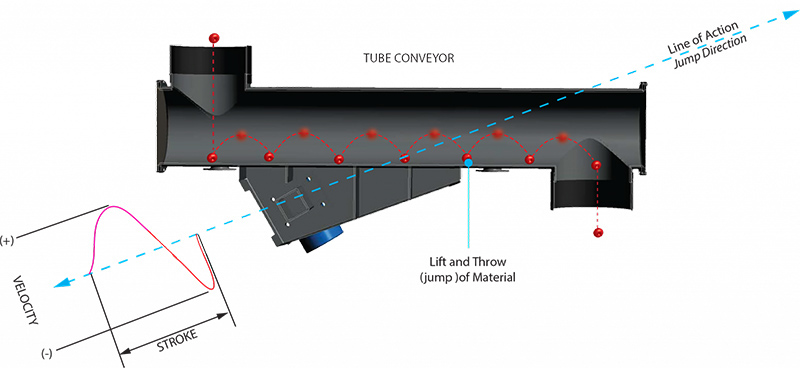

The working principle of the electromagnetic tube vibrating conveyor involves the interaction between an electromagnet and a tubular trough, resulting in a controlled vibration of the conveyed material. The following is a brief introduction to the working principle:

Electromagnetic Drive Unit: The conveyor system includes an electromagnetic drive unit located below the tubular trough. The drive unit consists of an electromagnet, which is essentially a coil wound around a magnetic core.

Generation of Electromagnetic Field: When current is passed through the coil of an electromagnet, a magnetic field is generated around the coil.

Attract and repel: The magnetic field generated by the electromagnet interacts with the tubular slot, which is usually made of a ferromagnetic material. As the magnetic field oscillates, it alternately attracts and repels the tubular slot.

Generation of vibrations: Periodic attractive and repulsive forces between the magnetic field and the tubular slot cause vibrations within the slot. The vibration frequency is directly related to the frequency of the alternating current supplied to the electromagnet.

Material Transport: The vibrating motion of the trough allows material to move along the length of the conveyor. As the chute vibrates, the material slides or moves along the chute, heading in the desired direction.

Gentle material handling

Provides a gentle delivery method that minimizes product damage or degradation. Controlled vibration ensures that delicate or fragile materials are transported without excessive shock or jostling.

Precise control

The conveying speed and vibration amplitude can be precisely controlled. This allows the conveying process to be fine-tuned to meet specific material requirements, ensuring optimum performance and efficiency.

Efficient transportation

The vibratory movement of the tank is conducive to the smooth flow and transportation of materials. It helps prevent material clogging, ensures consistent material flow and reduces the risk of blockages or bottlenecks in the delivery system.

Compact design

The compact design is suitable for installations where space is limited. They can be easily integrated into existing production lines or customized to specific layout requirements.

Dust free

The entire conveying process is carried out in a sealed pipeline, so a large amount of dust will not be generated, and the conveyed products will not be polluted.

Noise reduction

Solenoid tube vibrating conveyors produce lower noise levels during operation compared to other types of conveyors. This contributes to a quieter and more comfortable working environment.

Electromagnetic tube vibrating conveyor for rice

| Model | Production | Feed particle size | Frequency | Voltage | Tube diameter | Length | Distribution vibrator | ||

| (t/h) | (mm) | (min - 1V) | (V) | (mm) | (m) | Specification | Power (kw) | Length (m/section) | |

| GZ3G | 10 | 60 | 3000 | 220 | 250 | 2-10 | GZ3 | 0.2 | 2-2.5 |

| GZ4G | 15 | 70 | 300 | 2.5-12 | GZ4 | 0.45 | 2.5-3 | ||

| GZ5G | 20 | 80 | 340 | 2.5-12 | GZ5 | 0.65 | 2.5-3 | ||

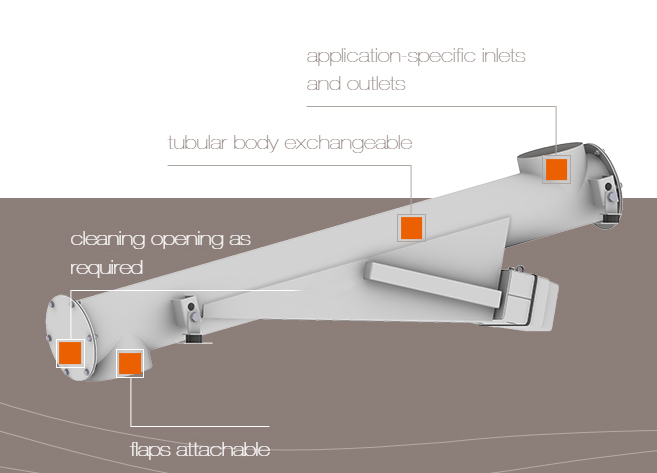

The structure of an electromagnetic tube vibrating conveyor typically consists of the following components:

Tubular Trough: The main component of the conveyor is the tubular trough or channel. It is usually made of metal or other suitable materials and serves as the pathway for the materials being transported. The trough is designed to be sturdy and durable to withstand the vibrations generated during operation.

Electromagnetic Drive Unit: The electromagnetic drive unit is responsible for generating the vibrations that propel the materials along the trough. It is located underneath the tubular trough and typically consists of the following elements:

Electromagnet: The drive unit contains an electromagnet, which consists of a coil wound around a magnetic core. The coil is connected to an external power source to generate a magnetic field when an electric current flows through it.

Control System: The drive unit is equipped with a control system that allows the operator to adjust the parameters of the electromagnetic vibrations, such as frequency and amplitude. This control system may include controls for current regulation, on/off switches, and adjustment knobs or buttons.

Power Supply: The drive unit requires an external power supply to provide the necessary electrical current for the electromagnet. The power supply may be connected to the drive unit through wiring or cables.

Base and Support Structure: The conveyor system is mounted on a base or support structure, which provides stability and rigidity. The base is designed to withstand the vibrations generated by the drive unit and the weight of the materials being transported.

Discharge and Inlet Chutes: The tubular trough may have discharge and inlet chutes at the ends to facilitate the entry and exit of materials. These chutes are designed to ensure smooth material flow into and out of the conveyor.

Support Springs or Mounts: To further enhance the vibration isolation and stability of the conveyor system, support springs or mounts may be used. These components help absorb vibrations and minimize their transmission to the surrounding environment.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.