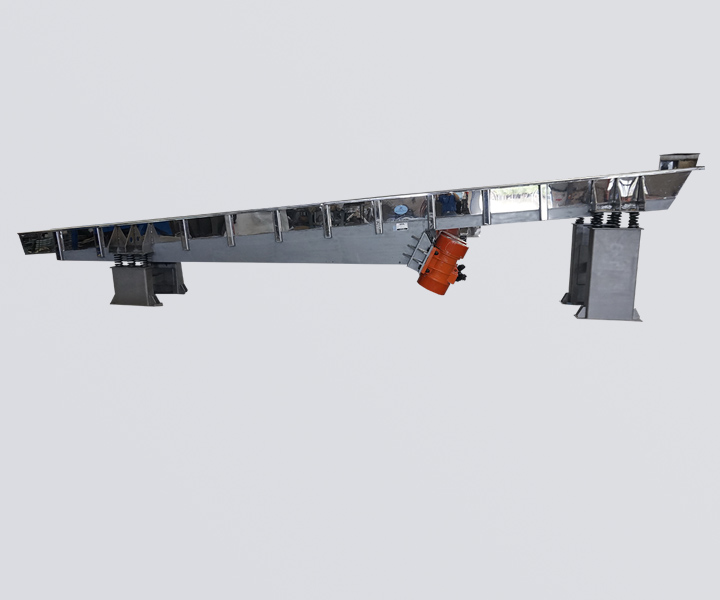

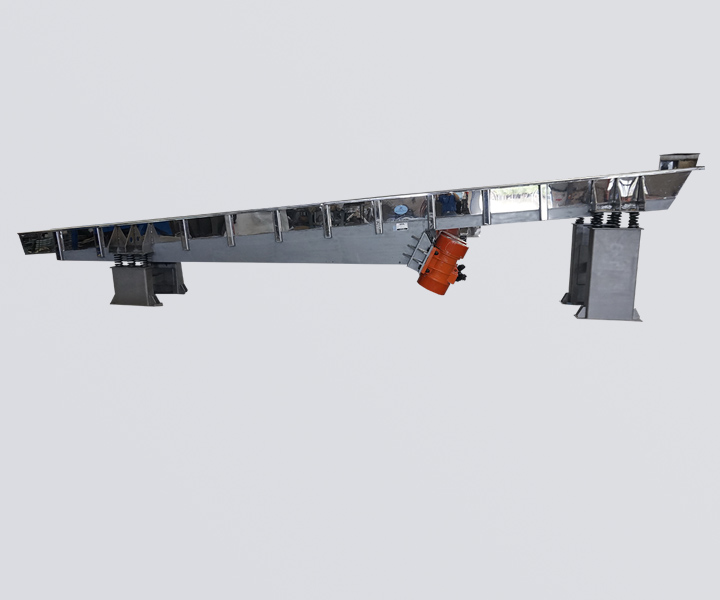

Stainless steel vibrating conveyor

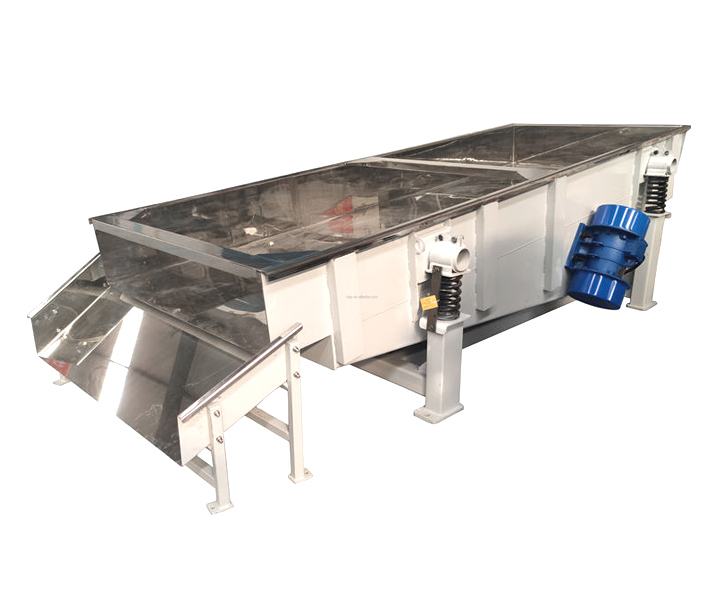

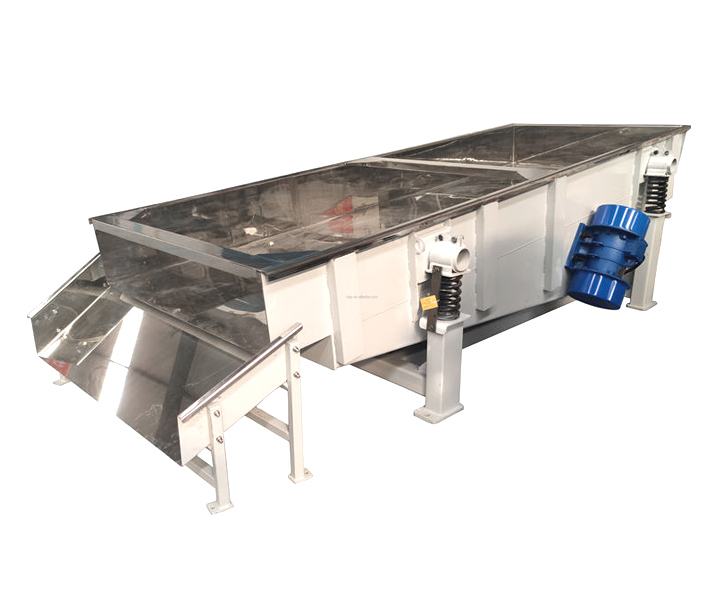

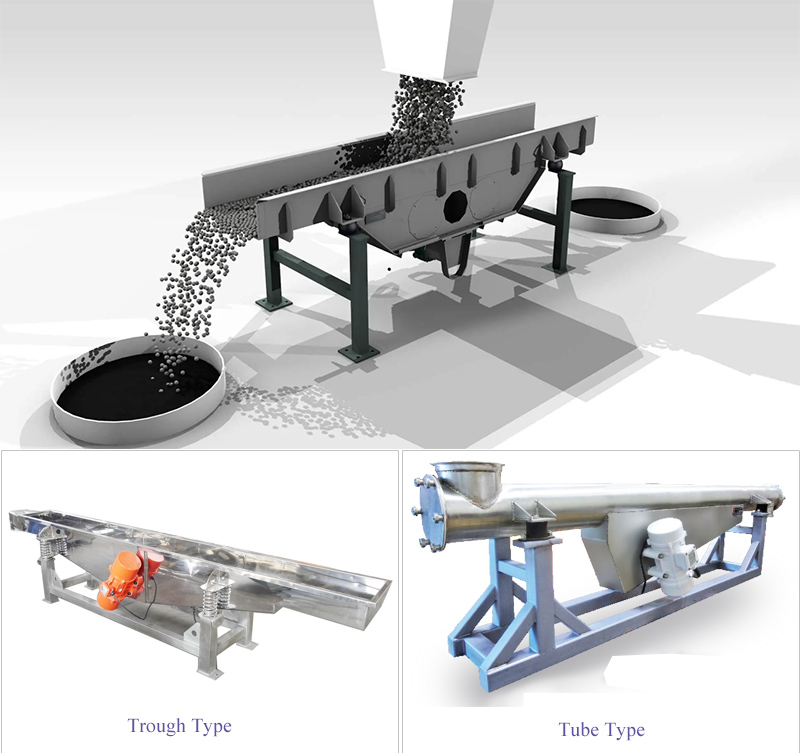

Stainless steel vibrating conveyor Stainless steel trough vibrating conveyor

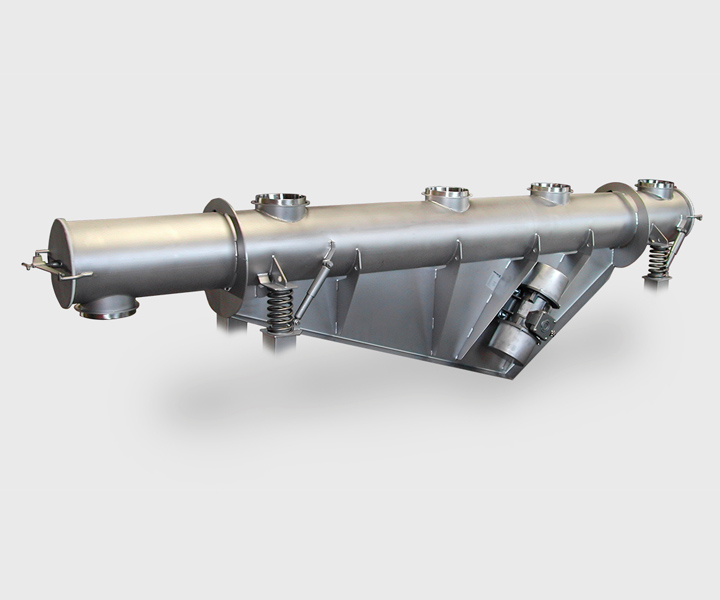

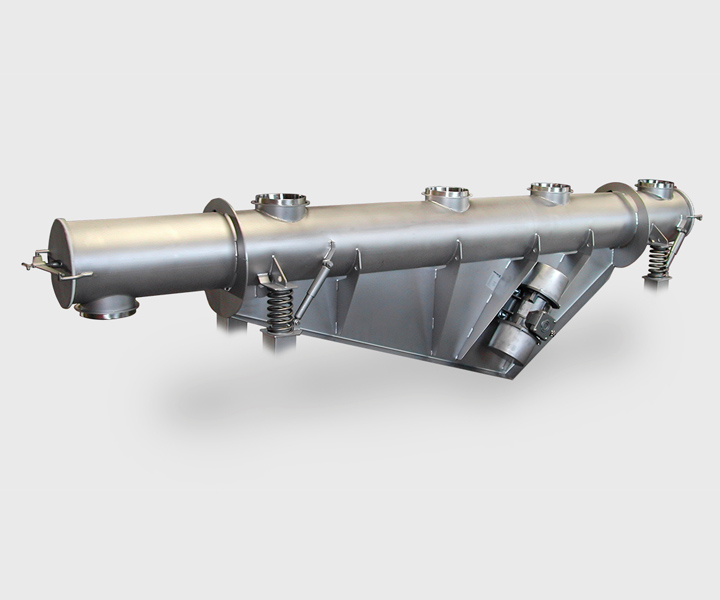

Stainless steel trough vibrating conveyor Stainless steel tube vibrating conveyor

Stainless steel tube vibrating conveyor Food grade stainless steel vibrating conveyor

Food grade stainless steel vibrating conveyor Multiple inlet stainless steel vibrating conveyor

Multiple inlet stainless steel vibrating conveyor

304/316L stainless steel, used for long-distance food, medicine, safe, clean and hygienic, to avoid material contamination

![]()

![]()

![]()

Price:$900.00-$5,000.00/Set

Consult now and enjoy a 10% discount

Material: Stainless Steel 304 or 316L

Type: Tube or Trough

Conveying length: ≤10 meters

Conveying capacity: 10-35t/h

Power: 2×(0.4-3)kw

Application: It is suitable for conveying all kinds of block and granular materials in medium and long distances (5-10 meters).

Stainless steel vibrating conveyor is made of SUS304 or 316L stainless steel. The surface finish grade is suitable for food and pharmaceutical industry applications. It minimizes material residues and ensures that the conveyed products are not polluted. It can remove various block, granular and powder materials from The storage bin or funnel is evenly and continuously fed to the receiving device, and the conveyor can be made into the form of one feeding and multiple discharging or multiple feeding and one discharging.

The trough width of stainless steel vibrating conveyor ranges from 6 inches to 5 feet, the length can reach 30 feet, and the conveying length can reach 10 meters. Multiple machines can be used in series to realize long-distance conveying.

Stainless steel vibrating conveyors are made of 304 or 316L stainless steel and are designed for food, pharmaceutical, chemical applications to convey and distribute materials evenly, where any contamination of the conveyed material must be strictly avoided, and in flour and Cleanliness and corrosion resistance are required in applications such as animal feed processing, plastics and chemicals, and the pharmaceutical industry.

1. Food processing

Stainless steel is used for polishing. The internal and external smoothness of the machine is 0.1-0.2RA, which is easy to clean. All welded joints are seamless, ensuring that there is no material deposition and the possibility of material contamination is zero. It meets the hygienic standards of the food industry and can transport things such as flour and salt. Granules, soybeans, peanuts, etc.

2. Feed processing

In the feed processing industry, it can be used for metering, extraction, feeding and conveying purposes, and can convey animal feed, aquatic feed, etc.

3. Pharmaceutical industry

Stainless steel vibrating conveyor is not easy to rust and will not cause pollution to pharmaceutical raw materials. It can transport pharmaceutical powder, pharmaceutical granules and decoction pieces, etc. The closed system eliminates the problem of dust in the air, ensuring dust-free operation and preventing material leakage.

4. Plastics and chemicals

Some plastic and chemical industries have weak acid and weak alkali, stainless steel screw conveyor can resist the erosion of acid and alkali materials, and will not damage the properties of materials.

Stainless steel vibrating conveyor

Stainless steel tube vibrating conveyor for fertilizer

SUS304/316L stainless steel

Stainless steel vibrating conveyors are made of stainless steel with a surface finish grade suitable for the application, reducing material residues to a minimum and ensuring no contamination of the conveyed products, especially suitable for the food and pharmaceutical industries.

Easy to clean and disinfect

The 304 stainless steel material can prevent rust, and the machine needs to be strictly polished to make the equipment easy to clean and disinfect in the later use process.

High temperature and corrosion resistance

Suitable for dry powder, wet powder, high temperature materials (temperature up to 200℃), corrosion resistance requirements.

Sealing structure

Good sealing performance reduces material spillage during transportation, and the surface pollutes the environment.

Long-distance transport

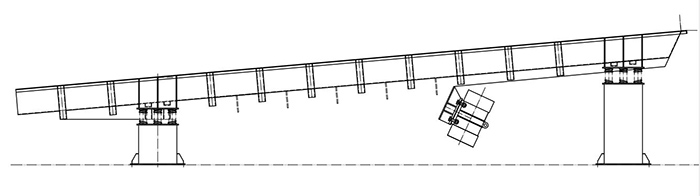

The trough widths from 6 inches to 5 feet, lengths up to 30 feet, conveying lengths up to 10 meters, and multiple machines can be used in series for long distance conveying.

Flexible layout

The feeding and discharging of the trough can also be made into the form of single-point/multi-point feeding, single-point/multi-point discharging and so on according to the needs.

| Model | Conveying Volume (t/h) |

Particle Size (mm) |

Trough Size (W×H mm) |

Conveying Length (m) |

Vibration Times (min-1) |

Motor Power (kw) |

Weight (kg) |

| DZS-250 | 10 | ≤50 | 250×250 | ~2.0 | 960 | 2×0.4 | 230 |

| DZS-300 | 15 | 300×300 | ~3.0 | 2×0.5 | 305 | ||

| DZS-400 | 20 | ≤100 | 400×300 | ~5.0 | 2×0.75 | 580 | |

| DZS-500 | 25 | 500×350 | ~6.0 | 2×1.5 | 880 | ||

| DZS-600 | 30 | ≤150 | 600×400 | ~8.0 | 2×2.2 | 1280 | |

| DZS-700 | 35 | 700×400 | ~10 | 2×3.0 | 1850 |

It can be made into three types of upper vibration type, lower vibration type and side vibration type, as well as three types of speed regulation type, normally open type and sealed type.

1. DZS series motor vibration conveyor can be made according to user needs.

2. Lower vibration type: the vibration motor is placed under the conveyor.

3. Upper vibration type: the vibration motor is placed above the feeder.

4. Speed regulation type: The vibration frequency of the vibration motor can be steplessly regulated within the rated frequency range.

5. Open type: the top of the conveyor is open, which is more suitable for the lower vibration type.

6. Sealed type: The conveyor is completely sealed except for the inlet and outlet.

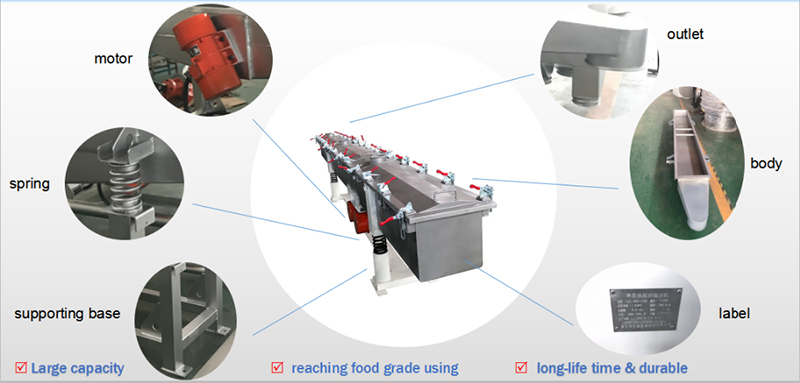

Stainless steel vibrating conveyor is composed of trough body, trough frame, bottom frame, main vibration spring, guide plate, vibration isolation spring, driving device and material inlet and outlet.

1. Driving device: It can be installed on both sides of the equipment, or on the upper or lower part. If there is no special requirement, it is generally installed on both sides.

2. The tank body: it is used to convey materials. It directly transfers energy to the materials during the vibration process, so that the materials can be continuously thrown along the conveying direction. You can choose U-shaped groove and tubular, and can also be made into open or sealed to meet different technological processes. The feeding and discharging of the trough can also be made into single-point/multi-point feeding, single-point/multi-point discharging and other types according to the needs.

3. The organic combination of the main vibration spring, the slot frame, the slot body and the base frame forms a complete elastic working system. When conveying materials, the elastic system works in a low critical resonance state, and the main vibration spring connects the slot frame and the base frame. It is elastically connected and supports a part of the weight of the trough frame and the trough body.

4. Guide plate: It guides the vibration direction of the groove frame and the bottom frame.

5. Slot frame: one is heat insulation, which separates the heat of the tank body from the elastic element when conveying hot materials; the other is that the heating and elongation of the tank body will not affect the working stiffness of the main vibration spring, so as to avoid serious bending vibration and vibration The third is to support and fix the trough body, so that the trough body and the trough frame form a complete working body.

Conveying grain or ingredients to the production line

The bulk grain unloaded by the ship unloader from the cabin is transferred to the granary for storage. During the transportation, multi-point feeding and multi-point discharging can be used, and quantitative feeding, metering and batching can be used.

Transfer powders and chemicals

SUS304 stainless steel is used. The higher the grade of stainless steel, the higher the cleanliness, the stronger the anti-rust and anti-corrosion functions. The sealed pipeline design is adopted. When conveying materials, because the materials are inside the closed loop pipe, they will not be conveyed again. Generate dust pollution.

For the food and bakery industry

The equipment is used to assist in adding ingredients to mixers and blenders, metering to downstream process equipment, sifting oversized or fine pieces from the final product, sprinkling salt, sugar or various seasonings, and supplying on demand during the packaging process.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.