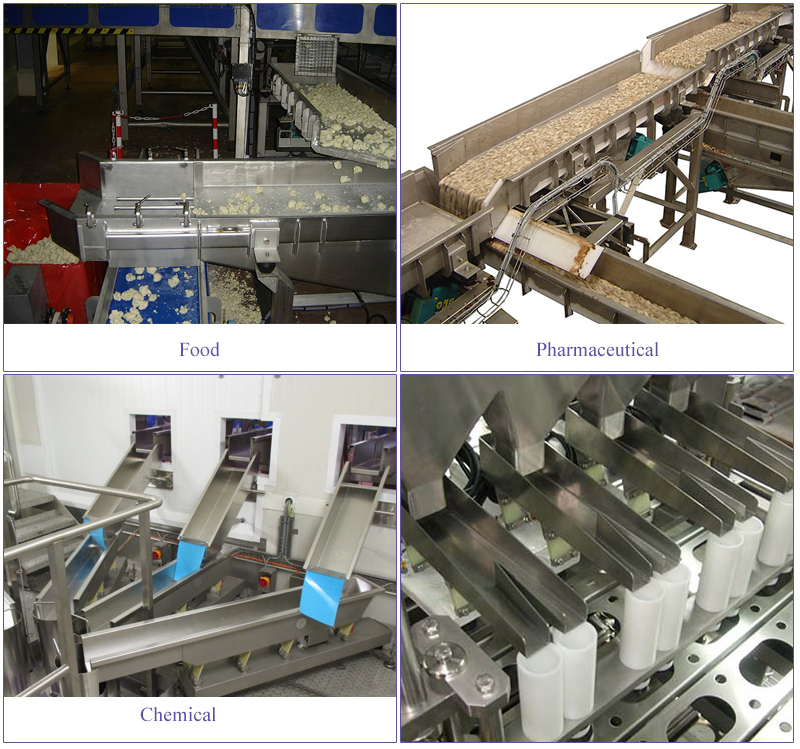

Mainly used for feeding, quantitative feeding, quantitative automatic packaging and other processes in food and pharmaceutical industries, and can realize automatic control and production process control

![]()

![]()

Price:$186.00-$1,700.00/Set

Consult now and enjoy a 10% discount

Bean: 50-500 - mm

Capacity: 10-1400 t/h

Double amplitude: 1.75 mm

Vibrating frquency: 3000rpm

Voltage: 220 v / 380 v

Application: FOR food, medicine, chemical industry all kinds of dry, wet, sticky, block, granular, powder, abrasive and other products for accurate feeding

Commitment:

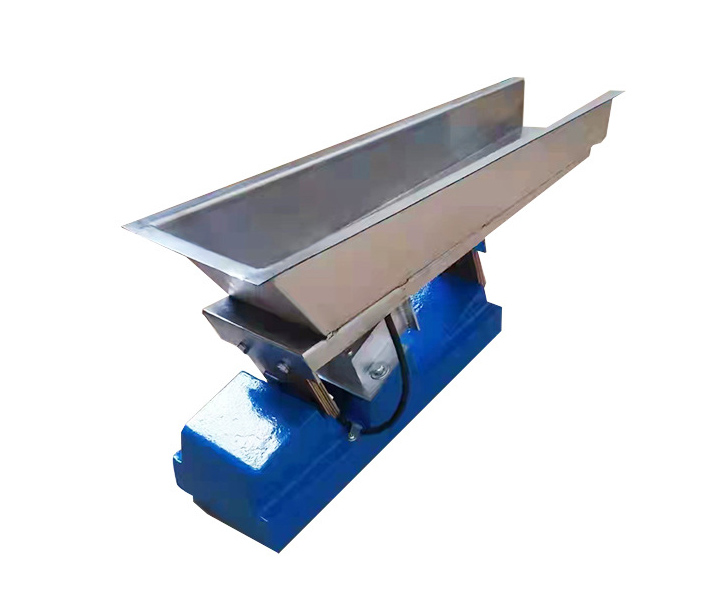

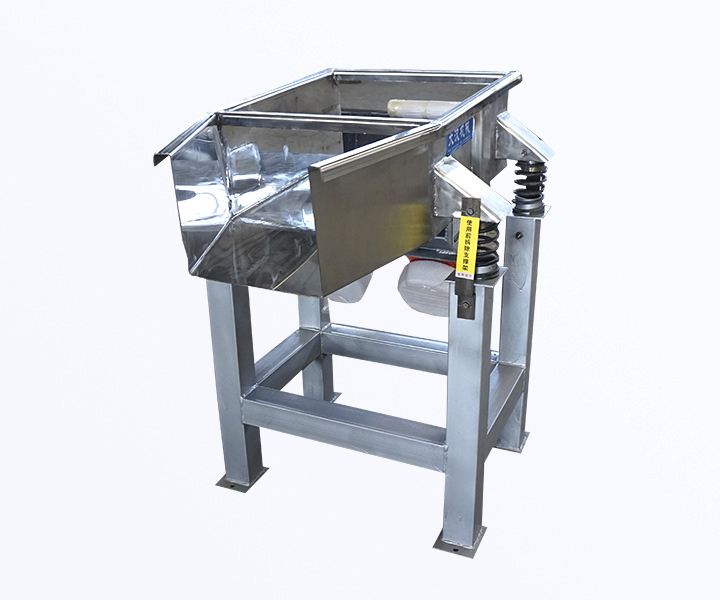

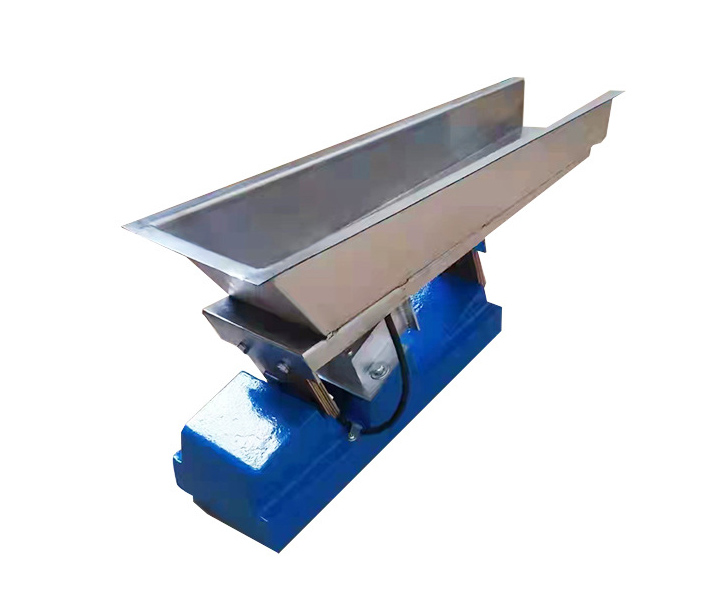

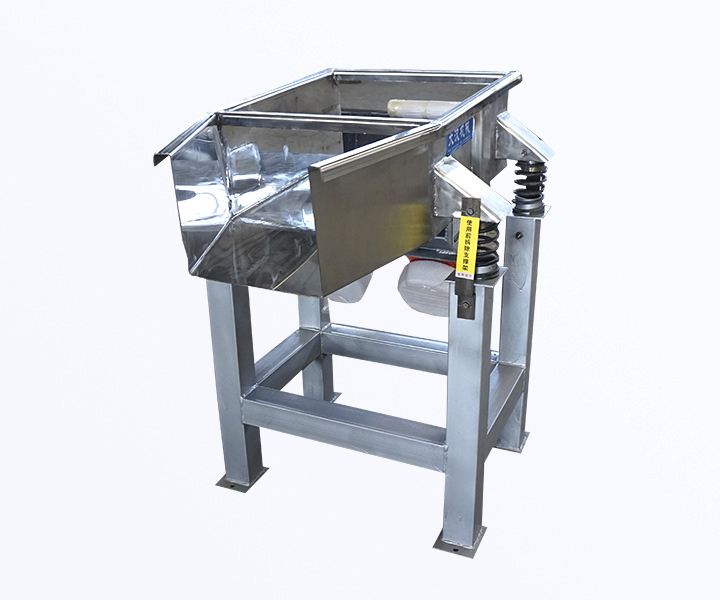

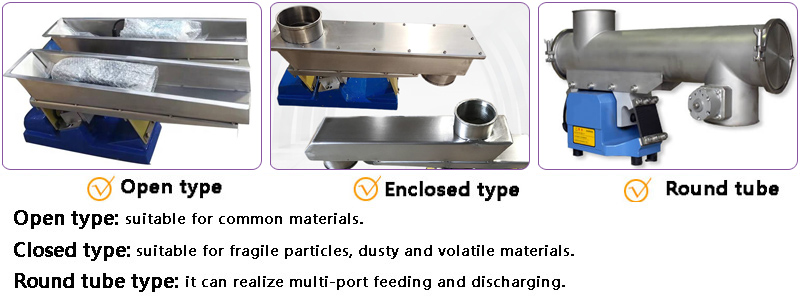

Stainless steel vibrating feeder is made of SUS304, and it is specially used in the food, pharmaceutical, and chemical industries to uniformly, continuously, and quantitatively send granular and powdery materials to the receiving device. Applications for cleanliness and perfect corrosion resistance, common applications include food, chemicals, pharmaceuticals and any other application that requires it for sanitation, corrosion or extreme temperatures.

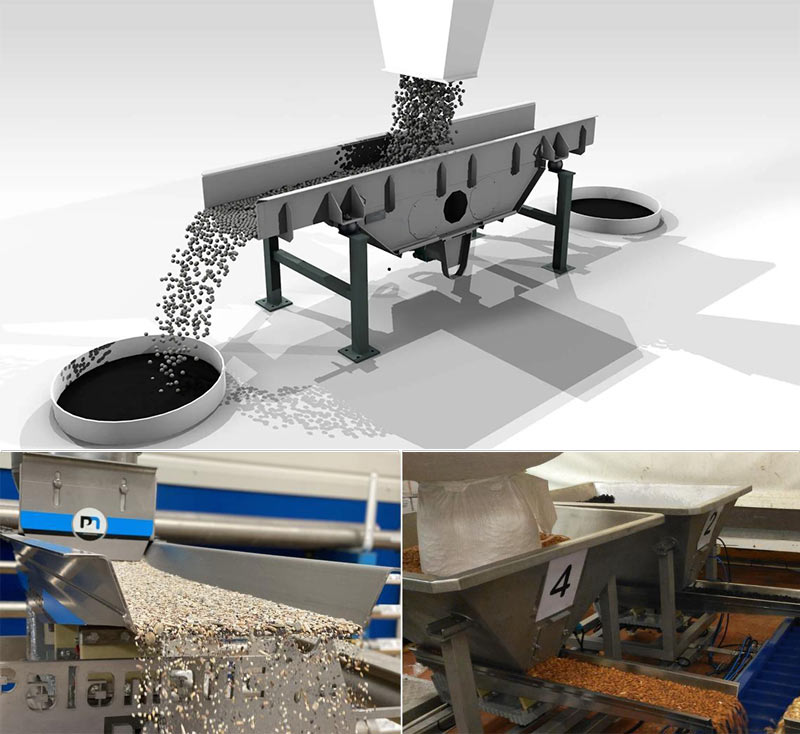

The stainless steel vibrating feeder is a fully enclosed structure that does not raise dust or scatter materials. There is no dust spillage during the entire conveying process. The material enters from the coal gate, passes through the inclined feeding chute, and reaches the tank body. The tank body is oriented by the vibration device. Periodic vibration, under the action of periodic exciting force, the material is output through the lower funnel.

Stainless steel vibrating feeders are used where any contamination of the processed material must be strictly avoided and absolute cleanliness and corrosion resistance are required, mainly in the environmental technology, flour and animal feed processing, food processing and packaging, plastics and chemicals and pharmaceutical industries . In the production process of feeding, batching and quantitative automatic packaging of powdery and granular materials, it can realize centralized control and automatic control.

Chemical industry: plastic granules, rubber powder, PVC granules

Abrasive industry: quartz sand, zirconium corundum, silicon carbide

Pharmaceutical industry: tablets, powders, granules

Food industry: rock sugar, potato chips, cocoa beans

Compliant with pharmaceutical grade and food grade

304 or 316 stainless steel material is polished, all welded joints are seamless, clean and hygienic to avoid contamination of conveyed materials.

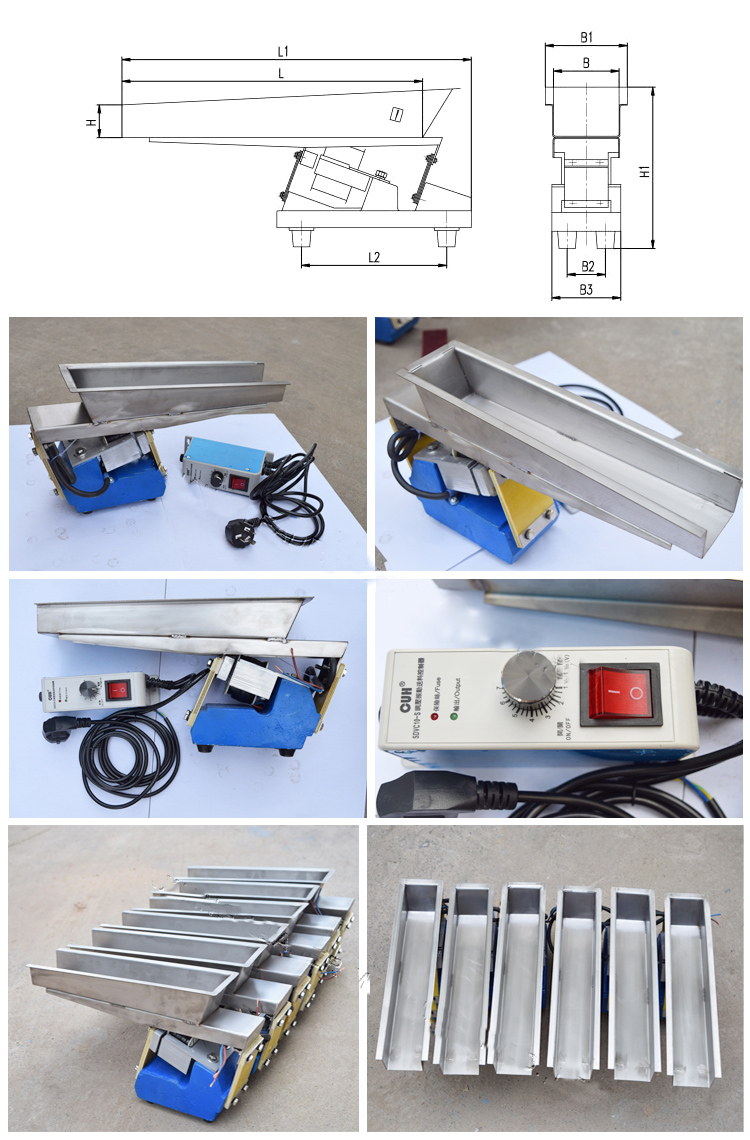

High feeding accuracy

The amplitude is 1.5-3mm, the vibration frequency is high, up to 3000 times per minute, and the material flow can be changed and opened and closed instantaneously, so the feeding amount has high accuracy.

Adjustable feeding amount

The control device adopts the thyristor half-wave rectifier circuit, so the feeding amount can be conveniently and steplessly adjusted by adjusting the open angle of the thyristor during use.

Low maintenance cost

The material in the feeding trough is continuously thrown up during the feeding process, and jumps forward according to the trajectory of the parabola, so the wear of the feeding trough is small, and the equipment replacement cost is low.

| Model | Productivity (t/h) | Feed particle size (mm) |

Double amplitude(mm) | Voltage (V) |

Current (A) | Power (KW) |

Matching control box | ||

| horizontal | —10° | Working current | Indicates current | ||||||

| GZ1 | 5 | 7 | 50 | 1.75 | 220 | 1.34 | 1 | 0.06 | XKZ-5G2 |

| GZ2 | 10 | 14 | 50 | 3 | 2.3 | 0.15 | |||

| GZ3 | 25 | 35 | 75 | 4.58 | 3.8 | 0.2 | |||

| GZ4 | 50 | 70 | 100 | 8.4 | 7 | 0.45 | XKZ-20G2 | ||

| GZ5 | 100 | 140 | 150 | 12.7 | 10.6 | 0.65 | |||

| GZ6 | 150 | 210 | 200 | 1.5 | 380 | 16.4 | 13.3 | 1.2 | XKZ-20G3 |

| GZ7 | 250 | 350 | 250 | 24.6 | 20 | 3 | |||

| GZ8 | 400 | 560 | 300 | 39.4 | 32 | 4 | |||

| GZ9 | 600 | 840 | 350 | 47.6 | 38.6 | 5.5 | XKZ-200G3 | ||

| GZ10 | 750 | 1050 | 500 | 39.4*2 | 32*2 | 4*2 | XKZS-200G3 | ||

| GZ11 | 1000 | 1400 | 500 | 47.6*2 | 38.6*2 | 5.5*2 | |||

The stainless steel vibrating feeder is composed of a trough, an electromagnetic exciter, and a shock absorber. The exciter is composed of an electromagnet (iron core and coil), an armature and a main vibration spring installed between the two. It is the excitation source that generates vibration. The work of the exciter can be controlled by a certain control device.

Application in food processing industry

Invited by a group company in Shanghai, it is necessary to purchase a feeder with a feeding capacity of 100KG, the conveying material is rice, and carry out quantitative control packaging. I want to use our stainless steel vibrating feeder to control uniform feeding. The process is as follows. The rice is put into the hopper, discharged through the outlet at the lower end, and enters into our feeder. The feeder controls the speed and feed amount, and then enters the next packaging equipment for controlled packaging to complete a simple feeding process. The material packaging production line has been used by customers very well, and will cooperate with our company in the later stage of preparation.

Application in the pharmaceutical industry

Whether you need to send needles, caps, vials or sterilized nails to a medical/pharmaceutical assembly line or packaging line, take advantage of the capabilities of a stainless steel vibratory feeder system, complete stainless steel construction, easy to clean components, pharmaceutical compliant industry production requirements.

Stainless steel vibrating feeder is one of the equipment on the batching production line of light industry, chemical industry, grain processing, commerce and other industries. It has good quality, simple structure, long life, low energy consumption and high efficiency. Feeding equipment, conventional shell cast iron material, can be customized (carbon steel, stainless steel), wear-resistant, high temperature resistance, corrosion resistance, long life, reasonable selection design according to working conditions, no jamming, uniform feeding, Made to size.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.