Square vibrating screen is specially designed to handle high feed flow rate. Double vibrating motors are installed, which together make the particles jump on the screen and separate the unwanted particles. By installing multiple layers of sieve plates with different meshes, the product can be separated into 2-7 different sizes.

The processing capacity is determined by the width and length of the screen surface. The wider the screen surface width, the thinner the material layer will be, and the larger the output will be. The higher the sorting efficiency, the screening area is available from 500mm to 1,500mm wide and 1,500 to 4,000mm long, allowing up to 20 t/h capacity.

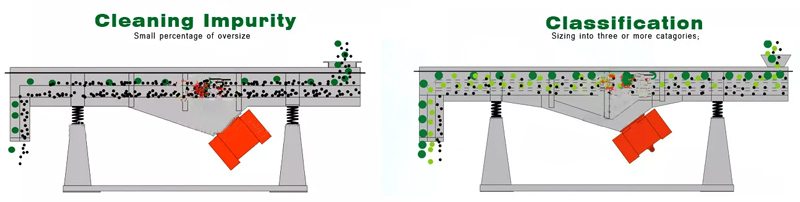

The square vibrating screen has the ability to convey while screening, and is often used for container filling and safety screening to remove agglomerates, oversized products or large particles in products that may affect subsequent processing or quality. Another common application is to combine a hopper with a screen to unload material from the hopper, remove fines and feed the material to the inspection station, thereby increasing inspection efficiency.

The Square vibrating screen uses a vibration motor as the vibration source and is driven by dual vibration motors. When the two vibration motors are rotated synchronously and in reverse, the excitation force generated by the eccentric block of the vibration motor cancels each other in the direction parallel to the axis of the vibration motor. The overlapping in the direction perpendicular to the axis of the vibrating motor is a resultant force, so the running track of the vibrating screen machine is a straight line. The two motor shafts have an inclination angle relative to the screen surface. Under the combined force of the exciting force and the self-gravity of the material, the material is thrown up on the screen surface and moves forward in a straight line, and the screens of various specifications are screened through different levels of screen meshes. The upper material and the lower material are discharged from different discharge ports.

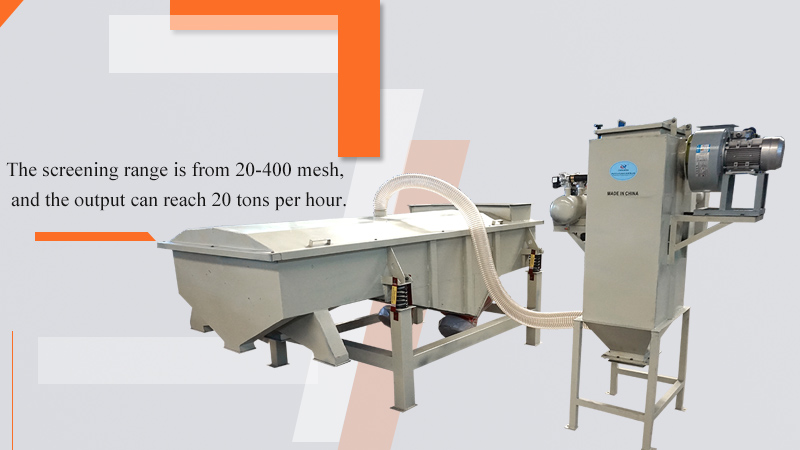

1. The screening range is from 20-400 mesh, and the output can reach 20 tons per hour.

2. Equipped with double motors, which are installed vertically to each other to obtain proper vibration flow. The arrangement of the double motors makes the screen frame move and vibrate in a straight line perpendicular to the motor, so that the super large particles have a good forward effect.

3. Materials can be screened into 2, 3, 4, 5, 6 or 7 different grades.

4. Equipped with an adjustable vibration motor, which can help achieve different speeds and vibration levels according to the degree setting.

5. The fully enclosed structure can ensure that there is no dust pollution during the screening process.

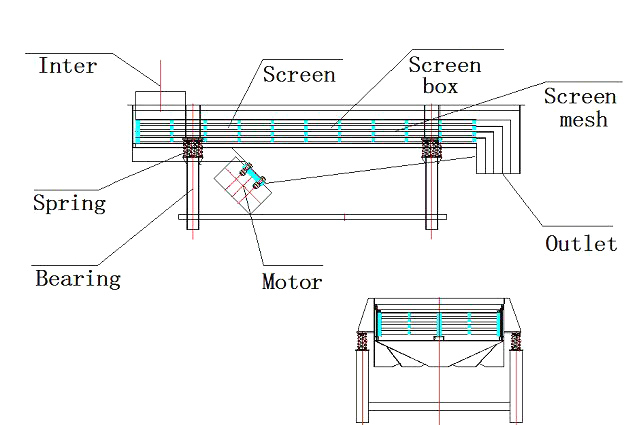

Square vibrating screen is mainly composed of screen box, screen frame, screen mesh, vibration motor, motor pedestal, vibration damping spring, bracket and so on.

Screen box: It is the main component of the square vibrating screen, which is welded by steel plates of various sizes.

Screen: It is the main working part and has various metal mesh classifications.

Vibration motor: It is the main power part, which drives the work of the entire square vibrating screen through the work of the vibration motor.

Shock-absorbing spring: used to prevent the stress of the vibration motor from working.

Bracket: The main part, which ensures the overall connection and normal work of the square vibrating sieve.

| Model | Layer |

Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Square Vibrating Screen Selection Notes

1. Model description: The regular models of Dahan square vibrating screen include: 515, 525, 530, 1025, 1030, 1240, 1530, 1540, etc. The model number represents the length and width of the square vibrating screen.

Such as: 525 type: 0.5 meters * 2.5 meters

2. Material description: Linear screen material can be selected:

1) Q235 carbon steel: The standard model is made of material, which has a wide range of uses, low cost and low investment.

2) The part in contact with the material is made of stainless steel: the bracket is made of carbon steel, which is often used in industries with high hygiene requirements such as food and chemical industry.

3) All stainless steel material: generally used in industries with very high hygiene requirements, such as medicine, food, etc., with internal and external polishing, no hygiene dead corners, in line with the hygiene standards of the food and pharmaceutical industries.

4. Level description: 1-6 layers of screen mesh can be optional.

The 1-layer screen can sieve the material into 2 different particle size grades.

The 2-layer screen can sieve the material into 3 different particle size grades...

Address:China,Yanjin county forest park gate to the west 1000 meters north road.