A conveying system that utilizes a continuous screw to transport material in a vertical or inclined direction. It is designed to move items between different floors or floors within a facility.

![]()

![]()

![]()

Price:$500.00 - $20,000.00/Set

Consult now and enjoy a 10% discount

Conveyor trough diameter: 300-900mm Height: ≤6 meters

Conveying capacity: 3.5 tons/hour

Power: 2* (0.4-3)kw

Frame material: SUS304/Carbon Steel

Speed: Adjsutable Speed

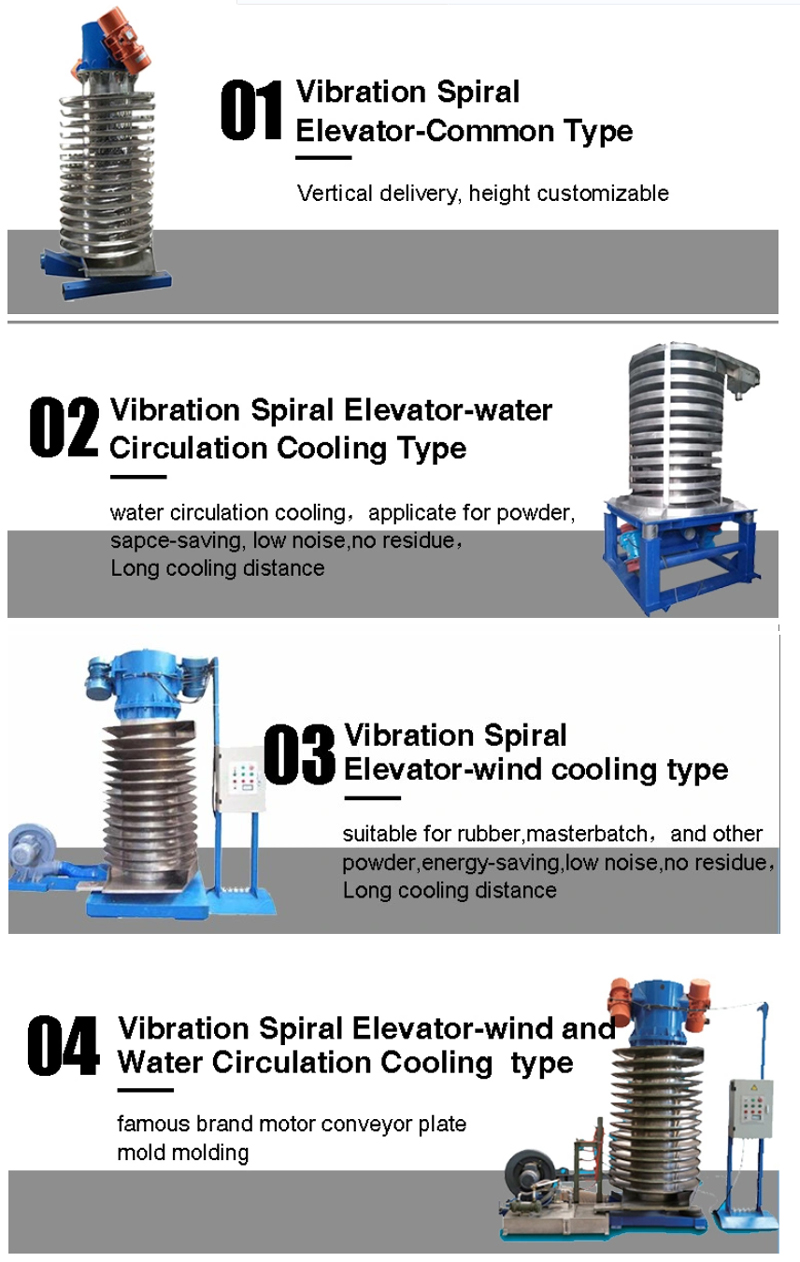

Customization: up-vibration, down-vibration, air-cooled, water-cooled, closed, open, 360-degree feeding, etc.

Application: For conveying and lifting powdery, lumpy and short-fiber materials.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

A spiral conveyor, also known as a spiral or helical conveyor, is a type of conveyor system that utilizes a continuous spiral-shaped belt or chain to transport materials in a vertical or inclined direction. It is designed to move items between different levels or floors within a facility while maximizing space utilization.

Spiral conveyors find applications in industries such as food processing, packaging, manufacturing, warehousing, and distribution, where efficient vertical or inclined transportation of materials is required.

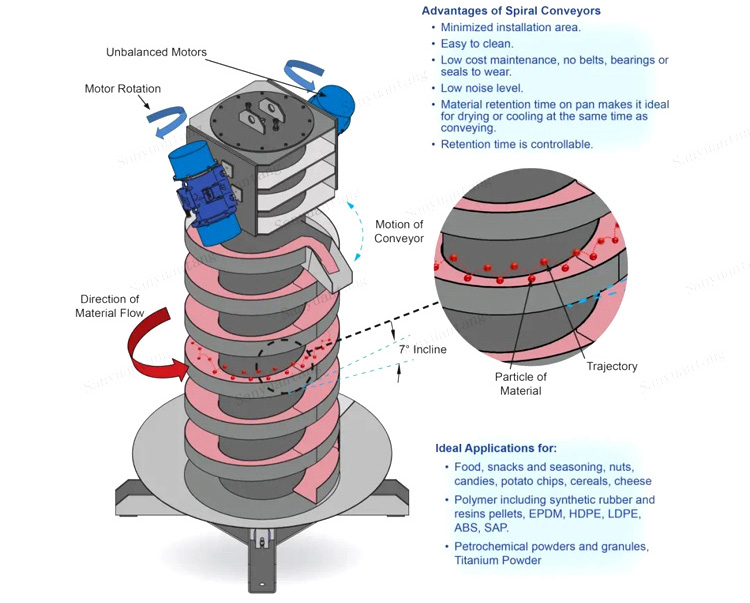

The working principle of a spiral conveyor involves the continuous movement of materials along a spiral-shaped path. Here's a breakdown of the working principle:

Loading: The materials to be transported are introduced onto the conveyor at the entry point, typically at ground level or a lower position. This can be done manually or by integrating the conveyor with other feeding mechanisms or upstream equipment.

Transport: As the spiral conveyor rotates, the materials are lifted or lowered along the spiral path. The shelves or platforms support the materials and move them in a controlled manner. The spiral design ensures a continuous flow of materials, eliminating the need for transfers or changes in direction.

Unloading: At the desired discharge point, usually at an elevated position or a higher level, the materials are unloaded from the conveyor.

Efficient vertical transport

Efficiently transport materials in vertical or inclined positions. They eliminate the need for separate lifts, hoists or inclined conveyors, simplifying material flow and reducing the overall complexity of the handling system.

Improve productivity

Helps increase productivity in material handling operations by providing a continuous flow of material, reducing product handling and transfers, and optimizing space utilization.

Space optimization

Its compact helical shape allows vertical or inclined transport while requiring a smaller footprint than conventional conveyors. This is especially beneficial for facilities with limited floor space or when using multi-story layouts.

Continuous flow

The helical design of these conveyors allows for a continuous flow of material without diversion or change of direction. This smooth, uninterrupted movement reduces the risk of product jams, jams or interruptions in the production process.

Gentle handling

The spiral motion minimizes the risk of product damage or spillage, ensuring safe transport of delicate or fragile items.

Easy to integrate

Can be easily integrated into existing conveyor systems or production layouts. They can be seamlessly connected to upstream or downstream equipment such as feeding mechanisms, sorting systems, packaging machines, etc.

Vertical Spiral Conveyor

Spiral Conveyor for Fertilizer

| Model | Diameter of Spiral chute(mm) | Lifting height (m) |

Speed (rpm) |

Double amplitude (mm) |

Power (kw) |

| DZC-500 | 50 | ≤6m | 960 | 6-8 | 2*0.75 |

| DZC-600 | 600 | ≤7m | 2 X 1.5 | ||

| DZC-800 | 800 | 2 X 2.2 | |||

| DZC-1000 | 1000 | 2 X3.0 | |||

| DZC-1200 | 1200 | 2 X4.5 | |||

| DZC-1500 | 1500 | 2 X5.5 | |||

| DZC-1800 | 1800 | 2 X6.0 |

Spiral conveyor usually consists of the following main components:

Vibrating platform or trough: It is a structure that holds material and vibrates. The vibration platform is usually made of steel plate or alloy material, which has sufficient rigidity and durability.

Vibrator: Vibrate the vibrating platform or tank by generating vibration force. The vibrator usually consists of an electric motor, an eccentric shaft or a vibration motor, and the vibration frequency and amplitude can be adjusted according to the needs.

Supporting Structure: Supporting structures are usually constructed of steel or other strong material with sufficient strength and stability.

Inlet and outlet: used for the entry and exit of materials. The feed port is usually located at the bottom for material supply, while the discharge port is located at the top or at an appropriate height for material unloading.

Control system: used to control the operation of the vibrator and adjust the vibration parameters. The control system may include components such as electrical control cabinets, sensors, and control panels so that the operator can monitor and adjust the operating status of the vertical vibratory hoist.

Food Processing: For applications such as lifting or lowering food during processing, packaging and distribution. They can transport items such as packaged goods, baked goods, frozen meals, snacks and beverages.

Bottling and Packaging: Transport bottles, cans, jars and other containers vertically. They can be integrated into fillers, labelers and packaging equipment to optimize product flows.

Pharmaceutical and Medical: For vertical transport of bottles, vials, syringes, blister packs and other medical products. They ensure efficient handling and positioning of materials during production and packaging.

Warehousing and Distribution: For vertical movement of various products including boxes, cartons and totes. They optimize space utilization and facilitate efficient material flow between different floors or mezzanines.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.