0-400 mesh can be screened, whether it is liquid or slurry 0-600 mesh can be filtered.

![]()

![]()

![]()

Price:$800.00-$4,500.00/Set

Consult now and enjoy a 10% discount

Mesh size: 2-500 mesh

Capacity: 100(kg/h)

Power: 0.18(kw)

Feed size: <10(mm)

Divided by material: carbon steel, stainless steel (for food and pharmaceutical industries), plastic (resistance to strong acid and strong alkali corrosion)

According to different industries: ordinary type, gate type (control material screening time), edge type (prevent liquid material from splashing), ultrasonic type (prevent material clumping and clogging)

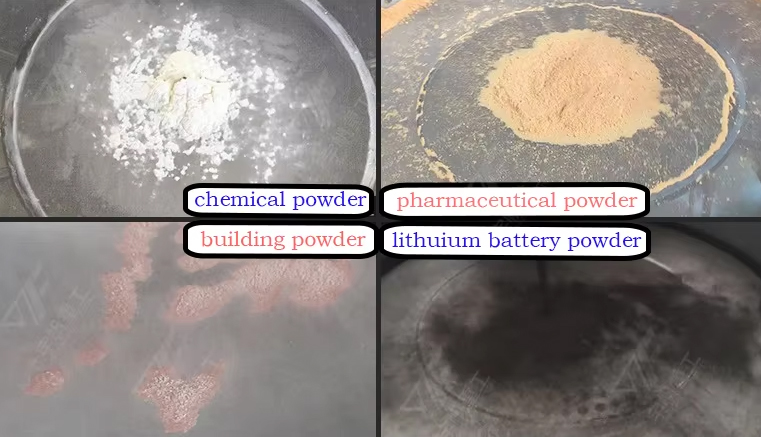

Application: Mainly used for screening, grading and filtering granular materials, such as flour, powdered sugar, starch, seasonings, chemical raw materials, etc.

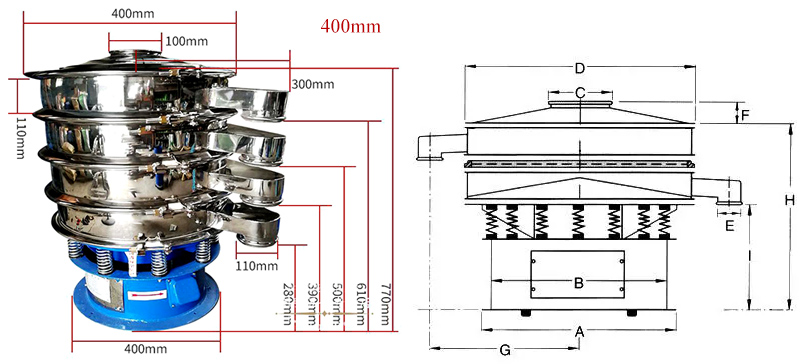

The small vibrating screen is a small type vibrating screen with a diameter of 400mm, the feeding particle size is less than 10mm, the motor speed is 1440 rpm, the motor power is 0.18kw, and the processing capacity per hour is 100kg. It is suitable for small batch production of various powders and slurries.

The small vibrating screen is suitable for the operation requirements of small screen weight. The size of the vibrating screen is not an inherent mode. It is designed and manufactured according to the screening requirements, material types, site restrictions and other conditions.

| Model | Diameter (mm) |

Feeding Size (mm) |

Frequency (RPM) |

Layers | Power (kw) |

| DH-400 | 400 | <10 | <1500 | 1-5 | 0.18 |

Small vibrating screens are often used in laboratories and some specific fields due to their small size. The main components are as follows:

Vibration motor: It will provide vibration force to make the entire screen vibrate. The vibration force of the vibration motor can be adjusted to meet the screening needs of different materials.

Screen body: The screen body is the part where the material is placed. It is a frame structure equipped with a screen.

Screen: The screen is mainly used to separate materials. The screening effect of different particle sizes can be achieved according to the aperture size of the screen.

Discharge port: The screened material is discharged through the discharge port. Generally, there are coarse material port and fine material port, which are used to collect the screened material and impurities respectively.

| Model | A | B | C | D | E | F | G | H | I |

| DH-400-1S | 380 | 280 | 150 | 400 | 100 | 70 | 280 | 715 | 350 |

| DH-400-2S | 380 | 280 | 150 | 400 | 100 | 70 | 280 | 825 | 350 |

| DH-400-3S | 380 | 280 | 150 | 400 | 100 | 70 | 280 | 935 | 350 |

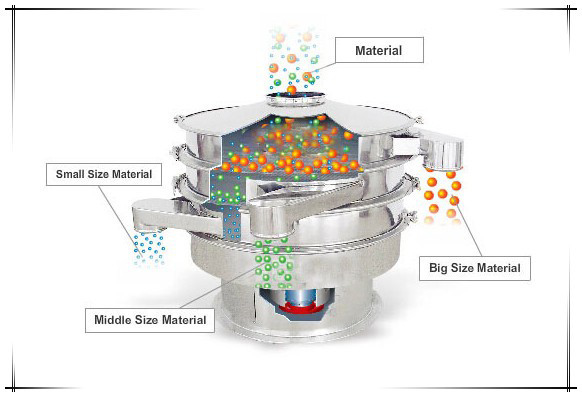

The function of a small vibrating screen (also known as a mini vibrating screen or compact vibrating screen) is to effectively separate and classify materials based on their size or other characteristics. Here are the main functions of a small vibrating screen:

1. Screening: The main function of a small vibrating screen is to screen and separate materials into different sizes or grades. This is essential for various industries to ensure that the final product meets the required specifications.

2. Grading: To grade materials into different size fractions or layers. This is very useful in industries where materials need to be separated into specific size ranges for different applications.

3. Dust removal: It can effectively remove dust, fine powder and other unwanted particles from the material. This helps to improve the quality of the final product by eliminating impurities.

4. Quality control: Small vibrating screens play a vital role in quality control to ensure that only materials of the required size and quality can pass through the screen. This helps to maintain product consistency and meet quality standards.

Common application scenarios of small vibrating screens in small batch screening:

1. Laboratory analysis:

Sample pretreatment: Before chemical analysis and physical testing, the sample is graded for particle size.

New material research and development: Particle size distribution analysis of newly developed materials to optimize the formula.

Drug research and development: Screening of drug raw materials to ensure the purity and uniformity of drugs.

2. Small batch production:

Electronic industry: Screening of electronic components, powder coatings, etc.

Food industry: Screening of food additives, seasonings, etc.

Cosmetics industry: Screening of cosmetic raw materials, such as powders, pigments, etc.

3. Scientific research and teaching:

University laboratories: Used for teaching experiments and demonstration of screening principles.

Scientific research institutions: Used for sample processing in scientific research projects.

The small vibrating screen uses a vertical vibrating motor as the excitation source. The upper and lower ends of the motor are equipped with eccentric weights to convert the rotation of the motor into a horizontal, vertical, and inclined three-dimensional motion, and then transfer this motion to the screen surface For screening, the user can change the movement trajectory of the material on the screen surface by adjusting the phase angle of the upper and lower ends.

Versatility

Despite its small size, small vibrating screens can achieve a variety of functions, such as screening, grading, filtering, impurity removal, etc., and are suitable for a variety of industries and application scenarios.

Accurate screening

Small vibrating screens can accurately screen materials of the required particle size, ensure product quality, and improve production efficiency.

Small footprint

Compared with large vibrating screens, small vibrating screens are smaller in size and occupy less space, suitable for use in limited spaces, especially for small production lines or laboratory environments.

Low cost

The price is low, the investment cost is relatively small, and it is suitable for small and medium-sized enterprises or occasions with limited budgets.

High flexibility

Small vibrating screens are usually designed to be flexible, easy to move and install, and can be moved or adjusted as needed to adapt to different production scenarios.

Easy maintenance

Due to the simple structure of small vibrating screens, maintenance is relatively easy, easy to clean and maintain, and production downtime is reduced.

Food industry: starch, salt, milk powder, soy milk, egg powder, soy sauce, fruit juice, etc.

Pharmaceutical industry: Chinese medicine powder, Chinese medicine granules, Chinese and Western medicine liquid, etc.

Chemical industry: resin, paint, industrial medicine, cosmetics, paint, Chinese medicine powder, etc.

Metals, metallurgy and mining: aluminum powder, lead powder, copper powder, ore, alloy powder, welding rod powder, manganese dioxide, electrolytic copper powder, electromagnetic materials, grinding powder, refractory materials, kaolin, lime, alumina, heavy carbonic acid Calcium, quartz sand, etc.

Pollution treatment: waste oil, wastewater, dyeing and finishing wastewater, additives, activated carbon, etc.

We are a company specializing in the manufacture and sale of small vibrating screens. Our small vibrating screens are mainly used for screening, grading, filtering and other operations of powder, granule and other materials, and are widely used in chemical, food, medicine, metallurgy and other industries. With a professional technical team and strict quality control system, we can customize solutions for customers to ensure that product quality and performance meet the best standards. We have been adhering to the business philosophy of "customer-centric, survival by quality, development by technology", constantly improving products and services, and creating greater value for customers.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.