The small vibrating screen is a widely used screening machine. Compared with other large-scale vibrating screens, it has the characteristics of lightness, flexibility and small footprint. It is suitable for users who have general requirements for material screening and output. Stainless steel, straight row, ultrasonic, plastic and other designs. This article will introduce the use of standard small vibrating screen to you, let's take a look:

1. Filter and remove impurities

For some production lines in the food industry or processing industry, the first step is to remove impurities in the material to obtain a relatively clean product. Or screen out unqualified finished products to control product quality.

The small vibrating screen is designed with a detachable screen box. The single-layer small vibrating screen can filter and remove impurities from materials with more impurities; after filtering impurities, the materials can be further processed.

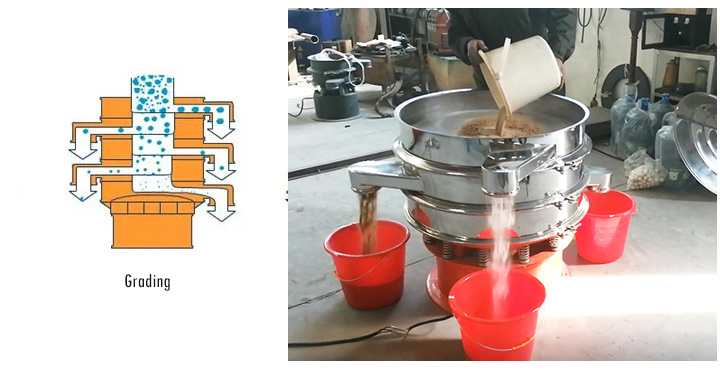

12. Uniform grading

Different fineness of some materials will have different uses, such as quartz sand, flour and other materials.

The small vibrating screen is equipped with multiple screen boxes and multi-layer screens, and the materials are screened layer by layer, and the maximum can be divided into 6 levels (5 layers). The screen machine can evenly screen the materials of each screen layer through three-dimensional motion. If there is a higher requirement for the uniformity and fineness of material classification, the edged small vibrating screen can be selected.

1Screen 0.028mm fine materials

The mesh of the small vibrating screen can be as fine as 500 mesh (0.028mm), which can meet the screening requirements of powder and liquid materials. If the material is very fine and prone to static electricity and clumping, it is recommended to choose a small ultrasonic vibrating screen and an explosion-proof motor for safer production.

1Screening output up to 3t/h

The screening output of the small vibrating screen is generally about 3-5 tons per hour for the large-scale vibrating screen.

In addition, if you need to screen corrosive materials with high hygiene standards, you can use a small vibrating screen made of 304/316 stainless steel, which can screen those materials with acid and alkali corrosion and high hygiene standards (lye paint, Aluminum chloride solution, flour, pharmaceutical preparations, etc.).

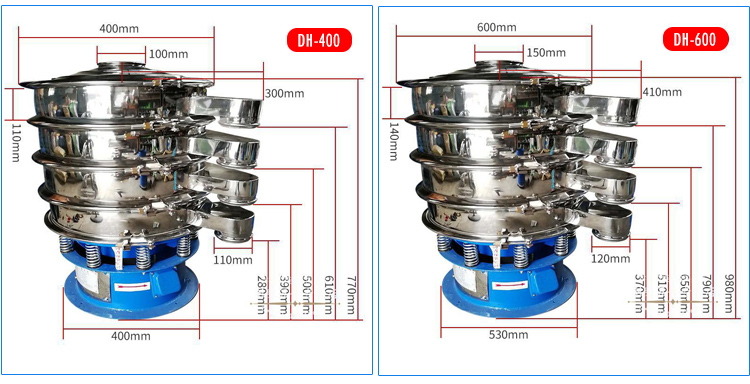

| Model | Diameter (mm) | Feed particle size (mm) | Speed (r/min) | Voltage (v)) | Power (kw) | Capacity (kg/h) |

| DH-400 | 350 | <10 | 1440 | 380 | 0.18 | 100 |

| DDH-600 | 550 | <10 | 1440 | 380 | 0.25 | 500 |

Food industry: flour, milk powder, condiments, beverages, juices, etc.

Pharmaceutical industry: raw materials of medicinal materials, Chinese and Western medicine granules, pills, etc.

Metallurgical industry: quartz sand, graphite, electromagnetic materials, electrolytic copper powder, etc.

The selection of mesh size usually depends on the particle size and screening accuracy of the material being screened. The following are some recommendations for commonly used mesh sizes:

20 mesh to 60 mesh: Suitable for screening larger particles, often used to screen impurities in granular materials.

60 mesh to 120 mesh: Suitable for powder and slurry impurities, and for the removal and classification of main materials.

120 mesh to 400 mesh: Suitable for screening flour, resin powder and other materials with finer particle sizes.

400 mesh and above: Used for high-precision screening of materials, mainly used for screening smaller impurities in materials or grading.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.