One deck of screen mesh and two discharge ports can quickly remove agglomerates, dust or foreign matter from the product in one screening process

![]()

![]()

Price:$650-$5000/set

Consult now and enjoy a 10% discount

Screen Mesh: 10 mm - 400 mesh (38 microns)

Width: 500-1500mm

Length: 2000-4000mm

Capacity: 10Kg-10Tons/Hour

Layer(s): 1-6 Layers

Motor Power: 2*(0.4-3.7)kw(Ordinary type or explosion-proof type optional)

Deck inclination: 0-15°

Applications: It is used in mining, metallurgy, chemical industry, building materials, food processing and other industries, and is used in many fields such as ore screening, sand and gravel classification, chemical raw material screening, and food

processing.

Commitment: Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

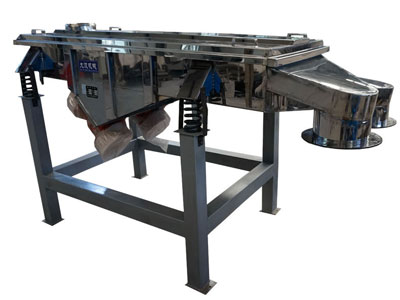

Single deck vibrating screen refers to a vibrating screen equipped with a single-layer screen and two discharge ports. It is mainly used to remove impurities, clumps, fibers, etc. in products to ensure the quality and purity of materials. Single deck vibrating screen mesh sizes range from 3/8 inch (10 mm) to 400 mesh (38 microns), with widths from 500 mm to 1,500 mm, screening areas from 1,500 to 4,000 mm long, and processing capacities of up to 20 tons/hour. Can be customized according to customer requirements.

Single deck vibrating screens serve multiple functions in various industries:

1. Screening and separation: Separate materials according to their size. It effectively screens the feed, allowing smaller particles to pass through the screen openings, while larger particles remain on the screen surface. This process aids in the classification and separation of materials.

2. Rejection and removal of oversized materials: In some applications, vibrating screens are used for rejection, which involves removing oversized or unwanted materials from the feed. This helps improve the efficiency of downstream processes and prevents equipment damage.

3. Removal of foreign matter: The vibrating screen can remove foreign matter or impurities from the materials being screened. This is particularly important in industries such as food processing, where maintaining product purity is critical.

Different types of Single Deck Vibrating Screen are designed to meet material handling requirements in different situations.

Carbon Steel Single Deck Vibrating Screen

It is usually painted, has no special properties, and is used for the treatment of conventional products.

Stainless Steel Single Deck Vibrating Screen

You can choose 304 or 316L material, which has the characteristics of high temperature resistance, corrosion resistance, sanitation and cleanliness, and has certain smoothness standards. It is usually used for processing special materials in the food and pharmaceutical industries, or for processing corrosive products in the chemical and environmental protection industry.

Single deck vibrating screen requires two vibrating machines to have an inclination angle relative to the screen surface. Under the combined force of the exciting force and the material's own weight, the material is thrown up on the screen surface and jumps forward, moving forward in a straight line. After a large number of crushed materials of different particle sizes and mixed coarse and fine particles enter the screen surface, only a part of the particles are in contact with the screen surface. The particles take the opportunity to pass through the gap and transfer to the lower layer. Because the gap between the small particles is very small, the large particles cannot pass through, so the originally disordered particles are separated, that is, stratified according to particle size, forming small particles on the bottom and coarse particles on the top. Arrangement rules, so as to achieve the purpose of screening and removing impurities.

Efficient

This vibration, along with the linear motion of the screen, effectively screens and separates materials. It ensures that a maximum amount of undersized particles pass through the screen, while oversized particles are retained, resulting in high screening efficiency.

Versatility

Versatile and can be used in a variety of materials and applications. They can handle a variety of particle sizes and types of materials, including ores, aggregates, chemicals, food and more. The screen's versatility makes it suitable for different industries and enables flexible screening solutions.

Cost-effectiveness

Single-deck vibrating screens are generally cost-effective compared to multi-deck screens or other complex screening equipment. Their design and construction are relatively simple, which helps reduce initial investment costs. In addition, its efficient screening capabilities help optimize production processes, thereby saving energy consumption and maintenance costs.

Easy to maintain

Routine maintenance tasks such as screen cleaning, inspection and screen replacement can be performed quickly and easily. This helps minimize downtime and ensure continuous operation.

1. Different uses: Single deck vibrating screen is for the screening of one material, and multi deck vibrating screen can be used for screening of multiple materials or a single material with multiple precisions.

2. Different feeding methods: the feeding amount determines the service life and output of the equipment. The single deck vibrating screen only handles one kind of material, and all materials can be appropriately increased. Since the multi deck vibrating screen handles multiple materials at the same time, it is necessary to pay attention to the amount of material when feeding.

| Model | Layer | Screening Area (mm) |

Mesh Size (mesh) |

Particle Size (mm) |

Capacity (t/h) |

Power (kw) |

Vibration Direction Angle (°) |

Screen Inclination (°) |

Dual Amplitude |

| DZSF-520 | 1-6 layers | 500*2000 | 2-400 | 0.074-10 | ≤3 | 0.37×2 | 45-60 | 0-7 | 3-4.5 |

| DZSF-525 | 500*2500 | ≤5 | 0.37×2 | ||||||

| DZSF-612 | 600*1200 | ≤8 | 0.37×2 | ||||||

| DZSF-1020 | 1000*2000 | ≤12 | 0.75×2 | ||||||

| DZSF-1025 | 1000*2500 | ≤16 | 0.75×2 | ||||||

| DZSF-1030 | 1000*3000 | ≤20 | 1.1×2 | ||||||

| DZSF-1224 | 1200*2400 | ≤23 | 1.5×2 | ||||||

| DZSF-1525 | 1500*2500 | ≤28 | 1.5×2 | ||||||

| DZSF-1530 | 1500*3000 | ≤32 | 2.2×2 |

Single deck vibrating screen is composed of feed inlet, dust cover, screen box, screen, outlet, vibrating motor, guide plate, shock-absorbing spring and base.

Screen: It is mainly used for screening materials. The aperture size of the screen is from 2 mesh to 200 mesh. There are many types and can be installed according to different screening requirements.

Screen box: The screen box is mainly used to hold the materials that need to be screened. The materials in the screen box are subjected to the action of the vibration motor to make a parabolic motion on the screen to achieve the purpose of screening.

Dust cover: The dust cover can solve the problem of dust when screening powdery materials;

Feed port and discharge port: The material enters the screen box from the feed port and is automatically discharged from the discharge port after being screened;

Vibration motor, force guide plate, shock-absorbing spring: The vibration force generated by the vibration motor drives the movement of the screen box through the conduction of the force-guide plate and the shock-absorbing spring, and the material moves on the screen, so as to achieve the purpose of screening.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.