Typically used in low-volume applications and where available space is limited.

![]()

![]()

Price::$500.00 - $6,800.00/Set

Consult now and enjoy a 10% discount

Feeding size: 25-70mm

Capacity: 1-6m³/h

Lifting height: 2-10m

Lifting speed: 1.4-2m/s

Application: Used to accurately and reliably handle a variety of materials from powders and granules to larger particles, such as grains, food raw materials, chemicals, building materials and other materials.

Commitment:Free Shipping/5 Days Delivery/30-Day Returns/Support Customization

Small bucket elevators are used in applications and processes that do not require equipment capable of moving large amounts of material, and are typically used to lift or lift small materials or bulk solids. It consists of a series of buckets attached to belts or chains that move vertically to transport materials. Small bucket elevators are typically compact in size and suitable for applications where space is limited.

The bucket width of a small bucket elevator is 160mm-250mm, the bucket volume is 0.5-4.6L, and the conveying capacity is 5.4-35 cubic meters per hour. Compared with large bucket elevators, small bucket elevators are designed to handle smaller capacity and height. They are commonly used in industries such as agriculture, food processing, mining and manufacturing that require vertical transportation of materials such as grains, seeds, powders, granules and small-sized bulk materials.

Small bucket elevators are used in many different applications, including but not limited to:

Food processing industry: used for vertical transportation of food raw materials, powders, granules, dried fruits and other food ingredients.

Agricultural field: used to transport grains, feed, seeds and other agricultural products, as well as various granular materials in agricultural production.

Chemical industry: suitable for vertical transportation of chemical products, such as fertilizers, plastic granules, chemical raw materials, etc.

Mining and building materials industry: used to transport coal, ore, gravel, cement and other materials, as well as various granular materials on construction sites.

Pharmaceutical manufacturing industry: used to transport pharmaceutical raw materials, pharmaceutical powders and other materials that need to be transported vertically during the pharmaceutical process.

Feeding hopper: ensure uniform feeding to ensure materials enter the elevator smoothly and avoid clogging or leakage.

Add movable wheels or movable base: it can be moved freely to adapt to different working areas or production line layouts.

Add a platform or guardrail: In order to facilitate operation and maintenance, a platform or guardrail can be installed on the small bucket elevator. This provides a safe working platform, allowing operators to more easily carry out inspections, repairs and cleaning tasks.

| Model | Hopper type | Transportation volume(m3/h)) | Bulk material(mm) | Model | Hopper type | Transportation volume(m3/h)) | Bulk materia(mm) |

| TD160 | Q | 5.4 | 25 | TD500 | Q | 38 | 60 |

| TD160 | h | 9.6 | 160 | TD500 | h | 70 | 60 |

| TD160 | zD | 9.6 | 25 | TD500 | zD | 58 | 60 |

| TD160 | Sd | 16 | 25 | TD500 | Sd | 92 | 60 |

| TD250 | Q | 12 | 35 | TD630 | h | 85 | 60 |

| TD250 | h | 22 | 35 | TD630 | zD | 89 | 60 |

| TD250 | zD | 23 | 35 | TD630 | Sd | 142 | 70 |

| TD250 | Sd | 35 | 35 | TD160 | Q | 4.7 | 70 |

Space-saving design

Small bucket elevators are compact in size and require less floor space than larger conveyor systems. They can be installed in areas with limited vertical space, making them suitable for facilities with limited space.

Efficient material handling

These lifts are designed to efficiently handle smaller volumes and heights. They can transport bulk materials vertically or at an angle, enabling efficient material transfer and distribution during the production process.

Gentle handling of delicate materials

Small bucket elevators are ideal for handling fragile or delicate materials such as grains, seeds and powders. Buckets are designed to minimize degradation or damage to materials during conveyance, ensuring the integrity and quality of the materials being conveyed.

Multiple material compatibility

Small bucket elevators can handle a variety of bulk materials, including grains, seeds, powders, granules and small-sized granules. They are suitable for different material types and can be customized with different bucket designs and materials to suit specific material characteristics.

Controlled discharge

These elevators provide controlled and precise material discharge at the desired location. The bucket is designed to ensure a smooth and consistent flow of material, preventing spills or uneven distribution.

Easy to maintain and operate

Small bucket elevators are generally designed to be easy to maintain and operate. They typically have simple structures and user-friendly controls that allow for easy maintenance, cleaning, and adjustment of operating parameters.

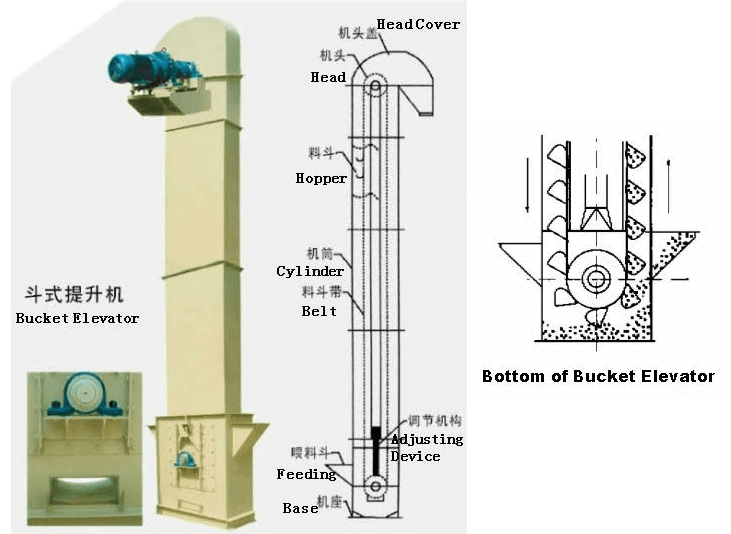

The structure of a small bucket elevator consists of several key components that work together to lift and transport materials. While the specific design may vary depending on the manufacturer and model, here are the main components typically found in the structure of a small bucket elevator:

Head section: The head section is located at the top of the elevator and houses the drive mechanism. It includes a motor, gearbox, and other components necessary for powering the elevator and driving the belt or chain. The head section also incorporates the head pulley, which is responsible for guiding and tensioning the belt or chain.

Boot section: The boot section is located at the bottom of the elevator and serves as the initial point where materials are loaded into the buckets. It includes a boot pulley that helps guide the belt or chain and maintains tension. The boot section often incorporates a boot hopper or inlet to facilitate the controlled entry of materials into the buckets.

Elevator belt or chain: The elevator belt or chain is the continuous loop that runs between the head and boot sections of the elevator. It is responsible for carrying the buckets and moving the materials vertically or at an incline. The belt or chain is specifically designed to withstand the load and abrasion associated with material handling.

Buckets: The buckets are attached at regular intervals to the elevator belt or chain. They scoop up the material at the boot section and carry it vertically or at an incline. The bucket design and material can vary depending on the specific application and material characteristics. They are typically made of durable materials such as plastic or metal.

Bucket fasteners: Bucket fasteners secure the buckets to the elevator belt or chain. They ensure that the buckets remain firmly attached during operation and withstand the weight of the materials being conveyed.

Casing: The casing provides a protective enclosure around the elevator structure. It helps contain the material being transported, prevents spillage, and ensures the safe operation of the elevator. The casing can be made of metal or other suitable materials, and it may feature access doors or inspection windows for maintenance and monitoring purposes.

Discharge chute: The discharge chute is located at the top of the elevator and serves as the point where materials are discharged from the buckets. It directs the material flow into the desired location, such as a receiving hopper, conveyor, or processing equipment.

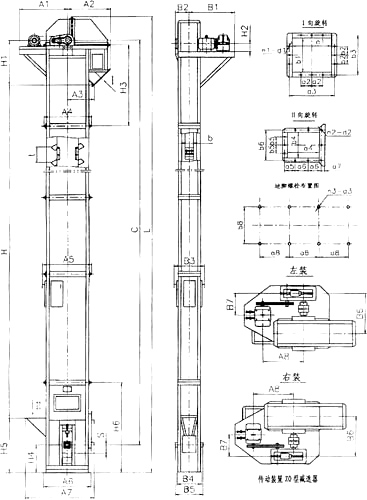

| Model | Profile height L | Overall structure | Bucket | Anchor hole | Inlet | |||||||||||||||

| H | H4 | S | t | b | a3 | b3 | n3 | d3 | H5 | a4 | a5 | a6 | a7 | b4 | b5 | b6 | n2 | d2 | ||

| TD100 | C+1100 | C-820 | 600 | 200 | 200 | 100 | 200 | 310 | 8 | Φ18 | 900 | 280 | 80 | 100 | 19 | 220 | 100 | 250 | 9 | Φ10 |

| TD160 | C+1363 | C-930 | 700 | 250 | 350/280 | 160 | 250 | 400 | 8 | Φ18 | 1000 | 260 | 80 | 100 | 19 | 220 | 100 | 250 | 9 | Φ12 |

| Model | Upper and lower casings and outlines | Discharge port | ||||||||||||||||||

| H3 | H6 | A2 | A6 | A7 | B2 | B4 | B5 | H1 | A3 | a1 | a2 | a3 | b1 | b2 | b3 | n1 | d1 | |||

| TD100 | 970 | 1210 | 692 | 776 | 1050 | 220 | 370 | 330 | 520 | 438 | 334 | 120 | 390 | 224 | 95 | 280 | 12 | Φ12 | ||

| TD160 | 1185 | 1500 | 985 | 996 | 1235 | 295 | 461 | 475 | 630 | 548 | 365 | 150 | 431 | 315 | 150 | 381 | 12 | Φ12 | ||

A chemical company customer successfully applied Xinxiang Dahan's small bucket elevator. They used the elevator for the transportation and storage of chemical raw materials, such as powder and granular chemical products. Through the small bucket elevator, the chemical company achieved efficient and stable transportation of raw materials, improved production efficiency and reduced manual handling. The customer highly praised the reliability, safety and ease of operation of the elevator.

Xinxiang Dahan small bucket elevator manufacturer is a manufacturer specializing in the production of small bucket elevators. The manufacturer is located in Xinxiang City and has many years of production experience and expertise. They are committed to providing small bucket elevator products of high quality, reliability and durability.

Xinxiang Dahan small bucket elevator manufacturer's product design and manufacturing comply with international standards and industry requirements. They use high-quality materials and advanced manufacturing processes to ensure product stability and long life.

The manufacturer focuses on technological innovation and product improvement, and constantly optimizes designs to meet the needs and applications of different customers.

In addition to high-quality products, Xinxiang Dahan small bucket elevator manufacturer also provides excellent after-sales service. They have a professional technical team and a complete after-sales support system, able to respond to customer needs in a timely manner and provide technical support and maintenance services.

When choosing a small bucket elevator, there are several key factors to consider:

Conveying capacity and lifting height: Determine the required conveying capacity (the amount of material transported per unit time) and lifting height (the vertical distance the material needs to be transported).

Material characteristics: Consider the characteristics of the transported materials, such as particle size, bulk density, fluidity, etc. Some materials may be abrasive, corrosive, or have special handling requirements.

Design and configuration: Consider factors such as bucket type (shape and size), bucket spacing, belt or chain type, drive system and discharge options.

Cost and ROI: Evaluate the overall cost of the bucket elevator, including initial investment, installation, operating costs and potential maintenance expenses. Also consider return on investment (ROI) and the long-term benefits a bucket elevator can provide in terms of increased productivity, reduced downtime and more efficient material handling.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.