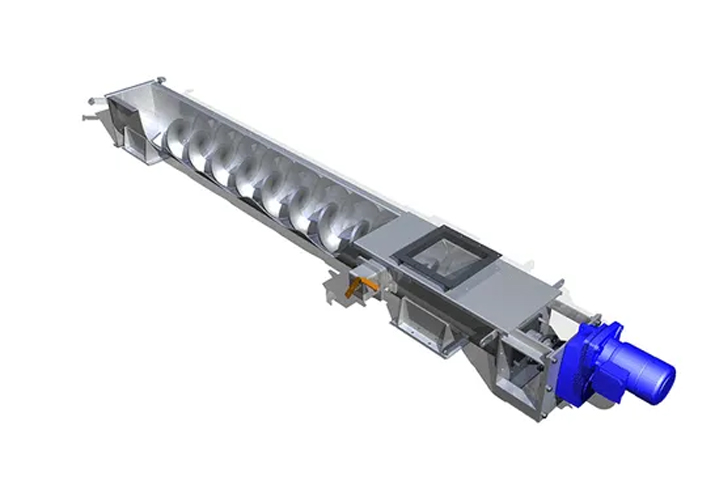

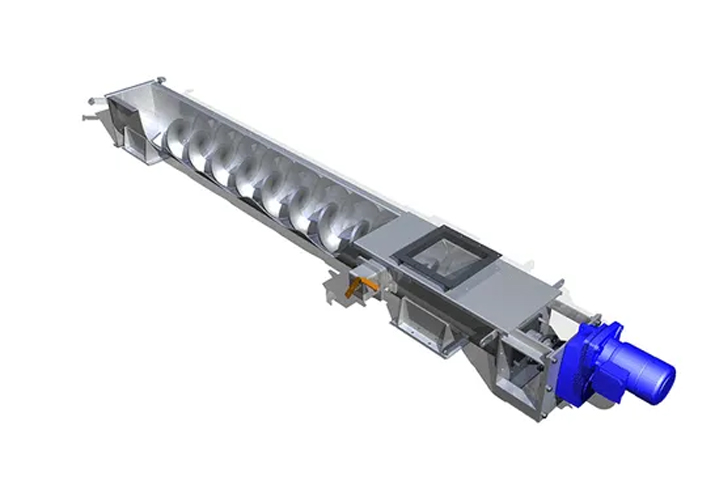

Mainly used in water and waste treatment plants for conveying slag from fine grid decontamination machines and sludge cake after sludge dewatering, etc.

![]()

![]()

![]()

Price:$750.00-$3,960.00/Set

Consult now and enjoy a 10% discount

Diameter: 150 - 470 mm Length: 30 m

Capacity: 0.8 mc/h-45 mc/h Power: 0.55 kW - 5.5 kW

Speed: 29rpm Inclination Angle: <40 degrees

Price: $750.00-$3,960.00/Set

Consult now and enjoy a 10% discount

Application: It can be used for the transportation of sludge, silt and mud cakes in various occasions, such as: sewage treatment plants, sedimentation tanks or thickening tank sludges in water works, sedimentation and coarse-grained sludge treatment from industrial wastewater, etc.

Commitment:

Slurry screw conveyors are used to handle and convey dewatered sludge, slurries from municipal sewage treatment processes, residential sewage pretreatment plants or livestock waste applications such as manure treatment systems, providing a non-clogging conveying surface due to the absence of intermediate bearings, , eliminates the accumulation of sludge and mud, and ensures barrier-free material handling. A fully enclosed tank prevents any material leakage, and tank covers with appropriate gaskets allow for odor-free operation and create a barrier to prevent any atmospheric agents from entering the system.

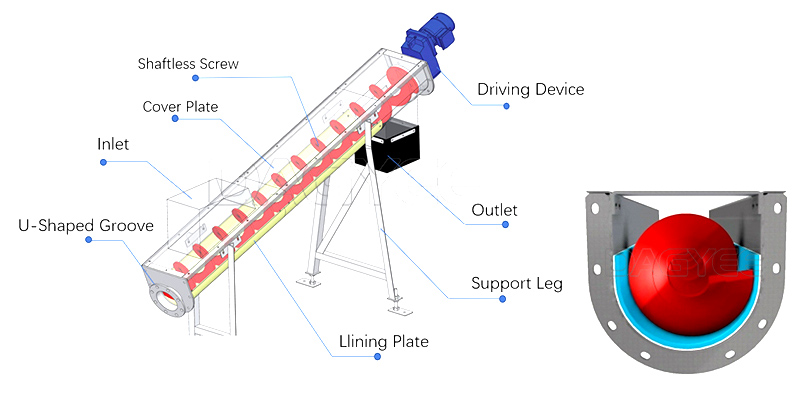

Shaftless screw (screw) allows for higher fill rates and lower rotational speeds, resulting in less wear, which reduces maintenance and downtime, delivering 1.5 times the throughput of conventional shafted screw conveyors of the same diameter.

Slurry screw conveyor is mainly used in sewage treatment plant to transport dewatered sludge and slurry to loading and unloading locations.

Conveying materials: It is used to transport sludge, mud, fine grids with a spacing of 50 mm in sewage treatment plants, transport grid slag of decontamination machines and mud cakes, sticky materials, coil materials, bulk materials, etc. of filter presses.

Conveying angle: It is suitable for horizontal conveying, and the inclination angle should not exceed 20 degrees according to the actual application.

SewageTreatment Plant

Conveying angle: 30 degrees

Conveying length: 25 meters

Conveying capacity: 3 tons/hour

Slurry After Dehydration of Domestic Sewage (moisture content 60%)

Conveying angle: 38 degrees

Conveying length: 10 meters

Conveying capacity: 10 tons/day

Sedimentation Tank

Conveying angle: 40 degrees

Conveying length: 8 meters

Conveying capacity: 20 cubic meters per hour

Conveying Oily Sludge (oil content 60%-80%)

Conveying angle: 40 degrees

Conveying length: 17 meters

Conveying capacity: 12 tons/day

Not easy to block

The sludge contains a lot of impurities and the fluidity is poor. The slimy screw conveyor adopts the design of no central shaft, and adopts the flexible integral steel screw to push the sludge. Strong anti-winding, will not cause material clogging.

Large delivery volume

Sludge is mainly used in industries that have certain requirements on conveying capacity, such as large sewage treatment plants. The conveying length of a single conveyor can reach 60 meters, and the conveying capacity is 1.5 times that of ordinary screw conveyors.

Long lasting

Due to the lack of an intermediate shaft, all the forces are on the blades, so the blades are required to have sufficient strength and rigidity, the thickness of the blades is not less than 20mm, and the height of the spiral blades is not less than 80mm, which can greatly extend the service life.

Low maintenance cost

When the material is conveyed, the blades are completed by the friction shell, so the shell needs a strong anti-friction force, and the addition of a lining plate can prevent the direct contact between the spiral body and the shell, which reduces the maintenance cost.

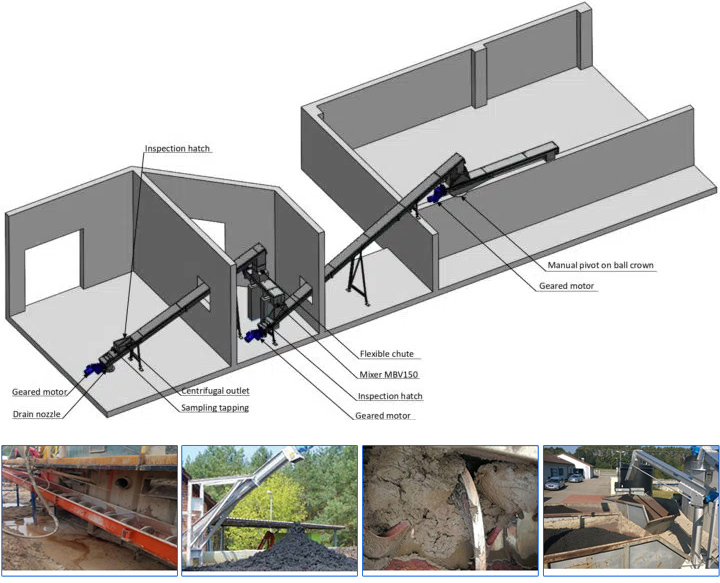

Flexible layout

Different layout methods can be adopted according to the conveying site. It can be conveyed horizontally or at a small inclination angle, and the inclination angle is not more than 25°.

No overflow

The sludge has high water content, serious pollution, easy to produce leachate, and overflow of odor. The fully enclosed and easy-to-clean spiral surface is used to reduce environmental pollution.

| Model | WLS150 | WLS200 | WLS250 | WLS300 | WLS400 | WLS500 |

| Spiral diameter(mm) | 150 | 184 | 237 | 284 | 365 | 470 |

| Outer diameter(mm) | 180 | 219 | 273 | 351 | 402 | 500 |

| Incline degree(a) | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° | 0 °-30 ° |

| Max Length(m) | 12 | 13 | 16 | 18 | 22 | 25 |

| Capacity(t/h) | 2.4 | 7 | 9 | 13 | 18 | 28 |

| Motor | Model | L ≤ 7 | Y90L-4 | Y100L1-4 | Y100L2-4 | Y132S-4 | Y160M-4 | Y160M-4 |

| Power kW | L ≤ 7 | 1.5 | 2.2 | 3 | 5.5 | 11 | 11 | |

| Model | L>7 | Y100L1-4 | Y100L2-4 | Y112M-4 | Y132M-4 | Y160L-4 | Y160L-4 | |

| Power kW | L>7 | 2.2 | 3 | 4 | 7.5 | 15 | 15Notes : The parameter above is just for reference, Model please inquiry us directly. We accept customization. |

Throughput: sludge up to 45 m³/h (26.4 cfm); screening flow up to 12.9 m³/h (15 cfm)

Material: Since most of the sludge contains corrosive materials, it is recommended to use stainless steel.

Transportation form: The conveyor is suitable for horizontal transportation, and the inclination angle does not exceed 20 degrees according to the actual application.

When the Slurry screw conveyor is to be stopped for a long time, the sludge and mud in the screw body and the U-shaped groove should be washed with water to prevent the conveying channel from being blocked after drying, and to avoid overloading when it is restarted.

Slurry screw conveyor is driven by the motor to drive the cycloid reducer, and the screw is rotated by the mechanical seal shaft and the connecting plate on the shaftless screw body. That is, the slurry is discharged from the outlet at the lower part of the U-shaped groove through the screw drive.

It is mainly composed of engine device, transmission device, casing, shaftless screw shaft, casing lining plate, feed port, discharge port, cover plate, base and so on.

Engine device: There is a motor transmitted to the cycloidal pinwheel reducer or the shaft-mounted hard-tooth surface gear reducer. The engine device should be located at the discharge port end as much as possible in the design, so that the spiral body is in a tension state during operation. . The transmission is equipped with thrust bearings, which can withstand the axial force generated when the conveyor is working.

Shell: U-shaped upper part is equipped with a rain-proof cover. The shell is made of stainless steel or carbon steel or FRP. The conveying process is basically airtight, which can effectively reduce indoor odors.

Shaftless helical shaft: will not cause blocking, the material is stainless steel or carbon steel.

Shell lining plate: The material is wear-resistant plastic plate or rubber plate, etc., with little wear and long service life.

Inlet and outlet: There are two kinds of square and round.

Installation method: The smooth screw conveyor produced by Dahan Company is normally ground-fixed.

According to the needs, we can provide hanging type: ground, hanging mixed type; mobile type, rotary type and turret type that can be rotated around the axis of the feed port.

Address:China,Yanjin county forest park gate to the west 1000 meters north road.